-

-

send us mail

[email protected]

The Carbon Steel Fittings are used in the oil and gas as well as the petroleum industries. While there are different types of carbon steels available in the market, it is the content of carbon or other elements is what makes them different. For instance, killed steel is an alloy which is completely de-oxidized. Which means that there is no free oxygen left in the alloy, thus the resultant alloy not only has a uniform composition, but the Killed CS Seamless Fitting also has superior toughness properties. The percentage of alloy present in Plain Carbon Steel Sch 40 Fittings is what usually affects properties such as weldability, hardening process and resistance to corrosion. The content of carbon present in these varieties of steels for e.g. Carbon Steel Elbow is what determines their use in manufacturing processes.

Carbon Steel Fittings

Carbon Steel Buttweld Fittings

Killed CS Seamless Fitting

Carbon Steel Fittings is primarily used across piping systems for its hardness, moderate to good tensile strength and inexpensiveness.

During the installation process of Carbon Steel Buttweld Fittings, these factors should be taken into consideration. Piping systems generally carry compressed gas at temperatures as low as -25°C to -4°C, making crack growth and brittleness an issue in the severe arctic environment. Therefore, steels such as Low Temp Carbon Steel Forged Pipe Fittings are used for applications involving natural gas piping systems, where they must meet more demanding requirements as compared to that of the oil industry.

| Standard Specification : | Carbon Steel Fittings |

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | MSS-SP-43 Type B Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, MSS-SP-43 Type b |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Coating Fitting Faces : | Cold and Hot Dip Galvanized, Zinc Plated, Yellow Transparent, Oil Black Paint, Anti-rust Paint |

| Carbon Steel Fittings Machining Equipment: | Press machine, electric bevelling machine, Bending machine, Pushing Machine, Sand-blasting machine etc |

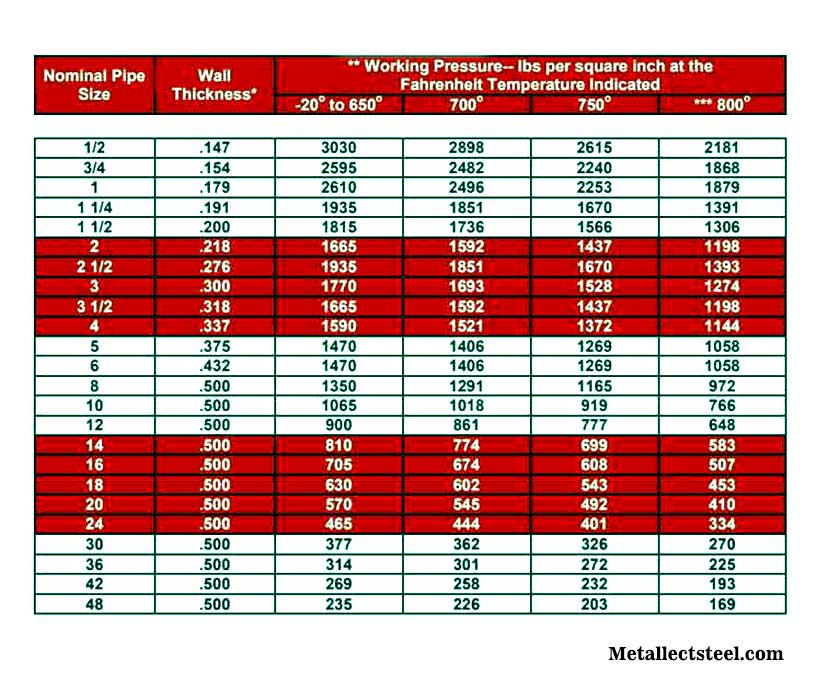

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Application: | Nuclear Power Plant Oil And Gas Industry Chemical Industry Natural Gas Industry Fabrication Industry Water Pipeline Industry |

| Element | Content (%) |

| Iron, Fe | Balance |

| Chromium, Cr | 18-20 |

| Nickel, Ni | 11-15 |

| Molybdenum, Mo | 3-4 |

| Manganese, Mn | 2 |

| Silicon, Si | 1 |

| Phosphorous, P | 0.045 |

| Carbon, C | 0.03 |

| Sulfur, S | 0.03 |

| Properties | Metric | Imperial |

| Tensile strength | 595 MPa | 86300 psi |

| Yield strength | 260 MPa | 37700 psi |

| Modulus of elasticity | 200 GPa | 29000 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 55% | 55% |

| Hardness, Rockwell B | 85 | 85 |

| Material | Fttg | ||||

| Carbon Steels | A234 Gr WPA | ||||

| A234 Gr WPB | |||||

| A234 Gr WPC | |||||

| Carbon Steels Alloy High-Temp |

A234 Gr WP1 | ||||

| A234 Gr WP11 | |||||

| A234 Gr WP12 | |||||

| A234 Gr WP22 | |||||

| A234 Gr WP5 | |||||

| A234 Gr WP9 | |||||

| Carbon Steels Alloy Low-Temp |

A420 Gr WPL6 | ||||

| A420 Gr WPL3 | |||||

| Material | Fttg | ||||

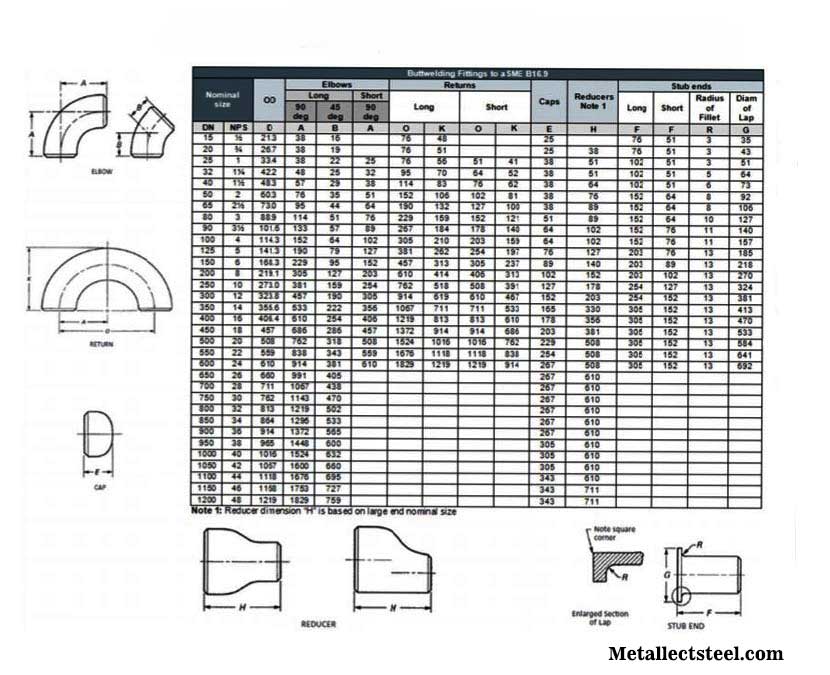

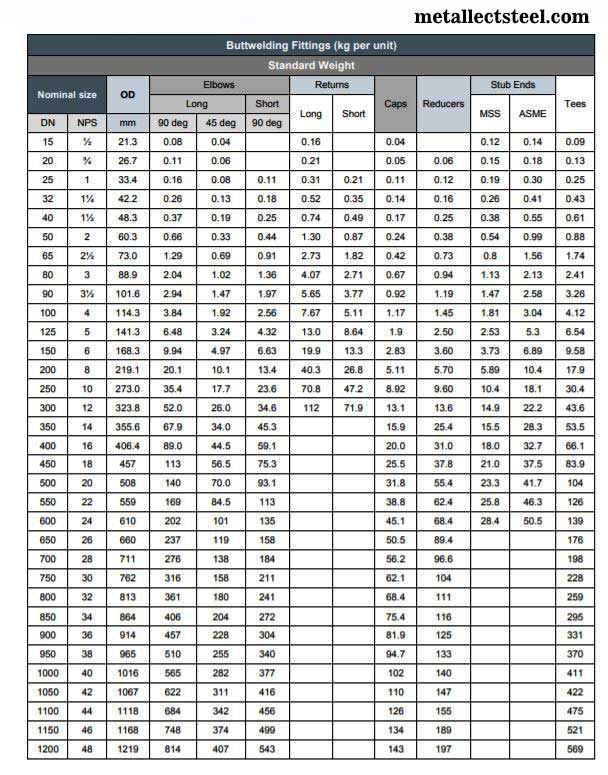

Check Carbon Fittings Size Chart

| Products | Size |

| Carbon Steel Cup | 1/2'' NB to 14'' NB |

| Carbon Steel Stub Ends | 1/2'' NB to 14'' NB |

| Carbon Steel Socket Weld | Upto 2'' NB |

| Carbon Steel Nipple | Upto 4'' |

| Carbon Steel Coupling | Upto 4''NB |

| Carbon Steel Elbow | 1/2'' NB to 14'' NB |

| Carbon Steel Reducer | 1'' NB to 14'' NB |

| Carbon Steel Tee | 1'' NB to 14'' NB |