-

-

send us mail

[email protected]

Ductile Iron is a kind of cast iron, which is renowned for several properties. For instance, ductile iron has superior impact and fatigue resistance, in addition to elongation, and wear resistance in comparison to cast iron. This is due to the presence of spherical or round graphite structures seen at a microscopical level in the Ductile Iron Pipe Fittings. This is also why ductile iron is referred to as spheroidal graphite iron or nodular iron names. As a result of a higher content of carbon in the metal, the 24 inch Ductile Iron Water Pipe Fittings retains the traditional qualities of cast iron such as high compression strength, abrasion resistance, castability, as well as machinability.

Ductile iron or Di Fittings also has what is referred to as an excellent wear resistance on account of the presence of graphite spheres in the iron.

When any component abrades itself against ductile iron fitting, the surface of the fitting will wear away much slower in comparison to many other metals. Wear resistance is a property of the Ductile Iron Pipe Bend Fittings that is partially inherited from the graphite structures present in the metal which behaves like a dry lubricant on the iron.

Ductile Iron Pipe Mechanical Joint Fittings also dissipates or it gets rid of heat very well and the metal can be machined fairly easily. Although, many manufacturers note that ductile iron is much harder to work with as opposed to regular gray cast iron. Moreover, when Ductile Iron Pipe Grooved Fittings are used, it dampens vibration and sounds much better in comparison to steel. Thus, making ductile iron an ideal match for use in large machines.

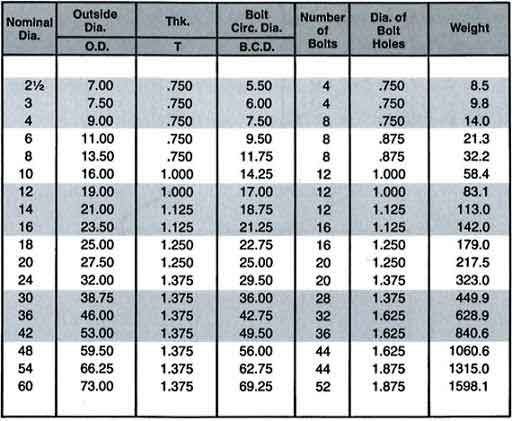

| NPS (in.) |

Outer Diameter (in.) |

B.C. (in.) |

T (in.) |

Bolt Hole Diameter (in.) |

Bolts | |

|---|---|---|---|---|---|---|

| No. Per Joint |

Size (inch) |

|||||

| 3 | 7.50 | 6.00 | 0.75 | 3/4 | 4 | 5/8 × 2 1/2 |

| 4 | 9.00 | 7.50 | 0.94 | 3/4 | 8 | 5/8 × 3 |

| 6 | 11.00 | 9.50 | 1.00 | 7/8 | 8 | 3/4 × 3 1/2 |

| 8 | 13.50 | 11.75 | 1.12 | 7/8 | 8 | 3/4 × 3 1/2 |

| 10 | 16.00 | 14.25 | 1.19 | 1 | 12 | 7/8 × 4 |

| 12 | 19.00 | 17.00 | 1.25 | 1 | 12 | 7/8 × 4 |

| 14 | 21.00 | 18.75 | 1.38 | 1 1/8 | 12 | 1 × 4 1/2 |

| 16 | 23.50 | 21.25 | 1.44 | 1 1/8 | 16 | 1 × 4 1/2 |

| 18 | 25.00 | 22.75 | 1.56 | 1 1/4 | 16 | 1 1/8 × 5 |

| 20 | 27.50 | 25.00 | 1.69 | 1 1/4 | 20 | 1 1/8 × 5 |

| 24 | 32.00 | 29.50 | 1.88 | 1 3/8 | 20 | 1 1/4 × 5 1/2 |

| 30 | 38.75 | 36.00 | 2.12 | 1 3/8 | 28 | 1 1/4 × 6 1/2 |

| 36 | 46.00 | 42.75 | 2.38 | 1 5/8 | 32 | 1 1/2 × 7 |

| 42 | 53.00 | 49.50 | 2.62 | 1 5/8 | 36 | 1 1/2 × 7 1/2 |

| 48 | 59.50 | 56.00 | 2.75 | 1 5/8 | 44 | 1 1/2 × 8 |

| 54 | 66.25 | 62.75 | 3.00 | 2 | 44 | 1 3/4 × 8 1/2 |

| 60 | 73.00 | 69.25 | 3.12 | 2 | 52 | 1 3/4 × 9 |

| 641 | 80.00 | 76.00 | 3.38 | 2 | 52 | 1 3/4 × 9 |

| Standard Specification : | Ductile Iron Pipe Fittings |

| Standard: | MSS-SP-43 Type A Fittings, MSS-SP-43 Type B Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, MSS-SP-43 Type b Fittings |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Application: | Natural Gas Industry Fabrication Industry Chemical Industry Water Pipeline Industry Nuclear Power Plant Oil And Gas Industry |

| Coating Fitting Faces : | Cold and Hot Dip Galvanized, Yellow Transparent, Oil Black Paint, Zinc Plated, Anti-rust Paint |

| Fitting Machining Equipment: | Press machine, electric bevelling machine, Bending machine, Pushing Machine, Sand-blasting machine etc |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| NPS | OD | 90 Deg Elbow | 45 Deg Elbow | 180 Deg Returns | ||||

|---|---|---|---|---|---|---|---|---|

|

(in.)

|

LR

|

SR

|

LR

|

LR

|

||||

|

(millimeter)

|

(in.)

|

Center to Face

(in.) |

Center to Face

(in.) |

Center to Face

(in.) |

Radius

(in.) |

Center to Center

(in.) |

Back to face

(in.) |

|

|

1/2

|

21.3

|

0.840

|

1 1/2

|

–

|

5/8

|

2

|

1 7/8

|

|

|

3/4

|

26.7

|

1.050

|

1 1/8

|

–

|

7/16

|

2 1/4

|

1 11/16

|

|

|

1

|

33.4

|

1.315

|

1 1/2

|

1

|

7/8

|

3

|

2 3/16

|

|

|

1 1/4

|

42.2

|

1.660

|

1 7/8

|

1 1/4

|

1

|

3 3/4

|

2 3/4

|

|

|

1 1/2

|

48.3

|

1.900

|

2 1/4

|

1 1/2

|

1 1/8

|

3

|

4 1/2

|

3 1/4

|

|

2

|

60.3

|

2.375

|

3

|

2

|

1 3/8

|

4

|

6

|

4 3/16

|

|

2 1/2

|

73.0

|

2.875

|

3 3/4

|

2 1/2

|

1 3/4

|

5

|

7 1/2

|

5 3/16

|

|

3

|

88.9

|

3.500

|

4 1/2

|

3

|

2

|

6

|

9

|

6 1/4

|

|

3 1/2

|

101.6

|

4.000

|

5 1/4

|

3 1/2

|

2 1/4

|

7

|

10 1/2

|

7 1/4

|

|

4

|

114.3

|

4.500

|

6

|

4

|

2 1/2

|

8

|

12

|

8 1/4

|

|

5

|

141.3

|

5.563

|

7 1/2

|

5

|

3 1/8

|

10

|

15

|

10 5/16

|

|

6

|

168.3

|

6.625

|

9

|

6

|

3 3/4

|

12

|

18

|

12 5/16

|

|

8

|

219.1

|

8.625

|

12

|

8

|

5

|

12

|

24

|

16 5/16

|

|

10

|

273.1

|

10.750

|

15

|

10

|

6 1/4

|

15

|

30

|

20 3/8

|

|

12

|

323.9

|

12.750

|

18

|

12

|

7 1/2

|

18

|

36

|

24 3/8

|

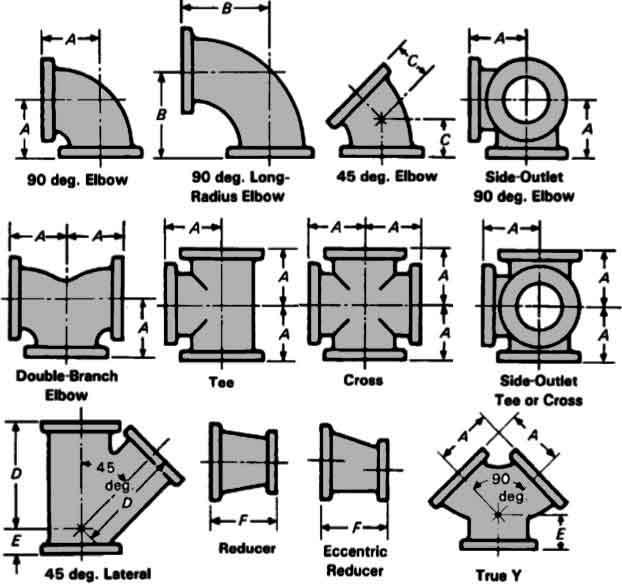

Ductile Iron U Bend

Ductile Iron Lateral Tee

Ductile Iron Socket Weld Union

Ductile Iron Cross

Ductile Iron Reducer

Ductile Iron Elbow

Ductile Iron Tee

Ductile Iron End Cap

Ductile Iron Stub End

Ductile Iron Threaded Plug

| Pressure Rating (psig) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | |||||||

| Allowable Stress (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | |||||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | |||

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | ||||

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | ||||

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | |||

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | ||||

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | ||||

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | |||

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | ||||

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | ||||

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | |||

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | ||||

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | ||||

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | |||

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | ||||

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | ||||

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | |||

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | ||||

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | ||||

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | |||

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | ||||

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | ||||

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | |||

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | ||||

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | ||||

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | |||

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | ||||

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | ||||