-

-

send us mail

[email protected]

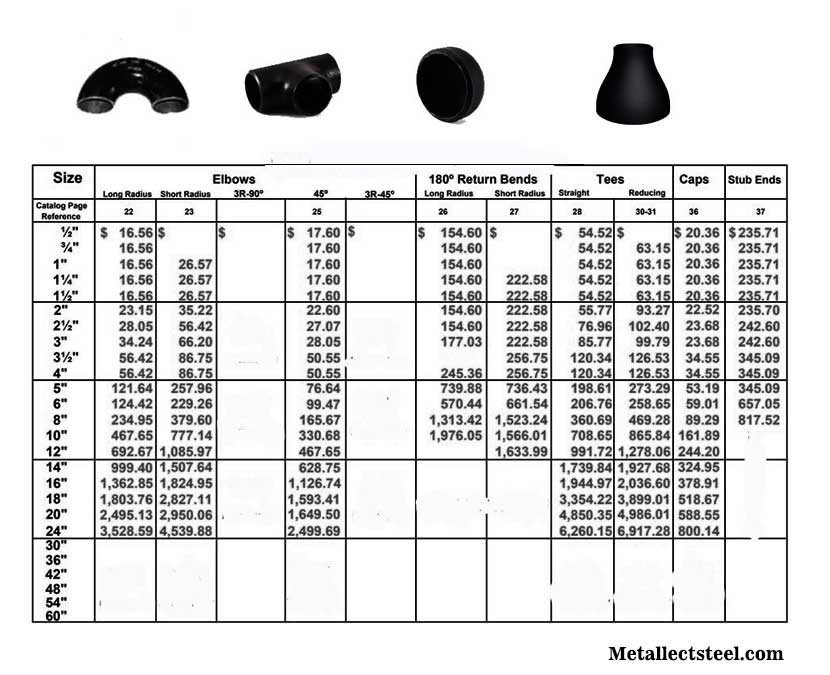

All types of Steel pipe fitting, including the ASTM A234 WPB Fittings, which have been manufactured from either carbon or alloy steel are designed with the intention of performing a function. In most instances, these fitting have been shaped to fit a profile in order to perform that particular function. This being said, most of the CS SCH 40 SA 234 Grade WPB Buttweld Pipe Fitting produced have a primary function, i.e. either to change the direction or the rate of the media in any pipeline systems. Mostly these specified ASTM A234 WPB Pipe Fittings include steel 45 degree elbow bend, 90 degree elbow bend , tees, concentric reducers or eccentric reducer, crosses, caps, flanges, nipples, gaskets, studs etc. If required, buyers also have the option of choosing a surface finished Bw A234 WPB Fittings, depending on the requirement.

ASTM A234 WPB Fittings

A234 WPB SMLS Pipe Fittings

SA 234 Grade WPB Buttweld Pipe Fitting

Chiefly used in applications involving medium to high temperature pipeline systems, the ASTM A234 standard steel pipe fittings are made from materials including different carbon and alloy steel grades.

| Gr. | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WPC | 0.35 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WP11 CL1 | 0.05-0.15 | 0.30-0.60 | 0.03 | 0.03 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

| WP11 CL2/3 | 0.05-0.20 | 0.30-0.80 | 0.04 | 0.04 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

For industrial purposes, in pipeline systems usually buyers have the requirement to change several aspects of the system, which are not limited to the transmission direction; but also to adjust the flow rate of various media i.e. water, slurry, oil and gas; Open or close the pipelines, etc. In order to undertake these activities, Carbon Steel A234 WPB Smls Pipe Fittings aid the worker to make relevant changes. Typically the SA234 WPB Material used in the production of these fittings includes wrought carbon steel and alloy steel fitting, which have the ability to withstand the demands of the industry if they have either a seamless or a welded construction.

| Standard Specification : | ASTM A234 WPB Fittings |

| Fitting Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine, Electric bevelling machine, Press machine etc |

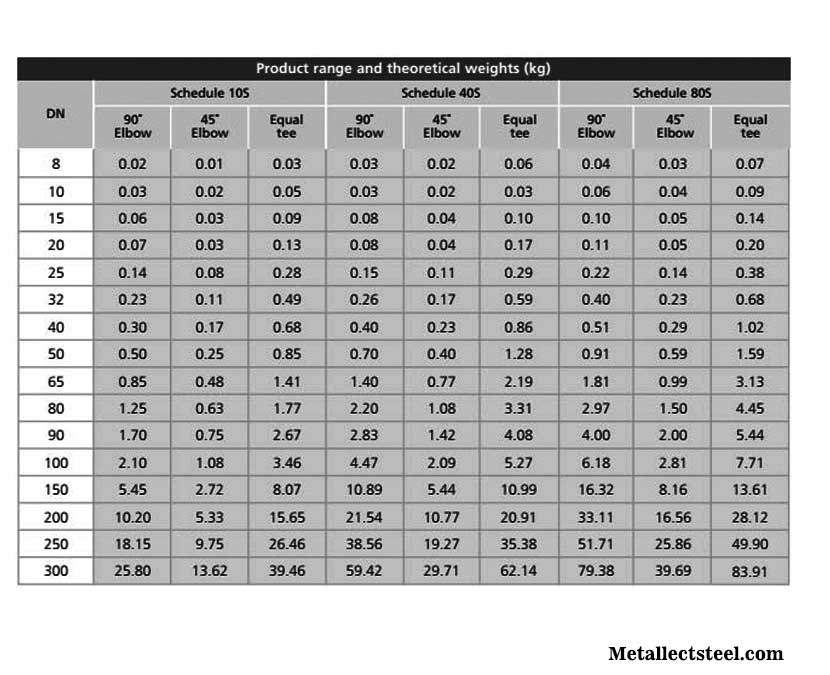

| Thickness: | View Our Thickness: SCH 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Coating Fitting Faces : | Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated, Yellow Transparent |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Standard: | ANSI B16.28 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, MSS-SP-43 Type B Fittings, JIS B2312 Fittings, MSS-SP-43 Type b Fittings |

| Application: | Fabrication Industry Water Pipeline Industry Chemical Industry Nuclear Power Plant Natural Gas Industry Oil And Gas Industry |

| Pipe | Fitting | Flanges | Valves | Bolts & Nuts |

|---|---|---|---|---|

| ASTM A106 Grade A | ASTM A234 Grade WPA | ASTM A105 | ASTM A216 Grade WCB | A193 Grade B7 A194 Grade 2H |

| ASTM A106 Grade B | A234 Grade WPB | ASTM A105 | ASTM A216 Grade WCB | |

| ASTM A106 Grade C | ASTM A234 Grade WPC | ASTM A105 | ASTM A216 Grade WCB |

| Tensile Requirements | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Tensile Strength, minimum, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% offset or 0.5% extension-under-load) | [415-585] | [485-655] | [415-585] | [520-690] |

| Yield Strength, minimum, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |