-

-

send us mail

[email protected]

However, the main task of the ASTM A420 WPL6 Elbow is to change the direction of the flow of media. Although there are three commonly used angles i.e. 22.5, 45 and 90 degrees, buyers could put in an order for a customized angle, depending on the requirement of the application. An ASTM A420 Gr WPL6 LR 45 Degree Elbow will change the direction of a piping system by an angle of 45 degrees. Elbows produced in accordance with the specification ASTM A420 could be either seamless or welded. Though a welded fitting could be surface treated to such a degree that the seam line on the fitting is invisible to the naked eye. The material used to manufacture the ASTM A420 WPL6 Buttweld Elbow Pipe Fittings is either alloy steel or carbon steel. Moreover, the material could be produced by any one of the three following processes i.e. open hearth, basic oxygen, or an electric furnace process.

ASTM A420 WPL6 Elbow

SA 420 WPL6 Elbow

Carbon Steel WPL6 Elbow

Like most fittings, an elbow is used to connect different pipes in the piping system.

Steel specimens such as the LTCS A420 WPL6 Elbow Fitting are to conform to required values of tensile strength, yield strength, chemical composition, elongation, wall thickness, as well as Charpy V-notch impact value. All fusion welded butt joints Carbon Steel WPL6 Elbow are subjected to a radiographic examination, while hydrostatic testing of fittings like the SA 420 WPL6 Elbow is not required in per the ASTM A420 specification.

| Standard Specification : | ASTM A420 WPL6 Elbow |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Thickness: | View Our Thickness: SCH 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | ANSI B16.9, MSS-SP-43 Type b, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, ANSI B16.28, JIS B2313 |

| Coating Fitting Faces : | Cold and Hot Dip Galvanized, Zinc Plated, Oil Black Paint, Anti-rust Paint, Yellow Transparent |

| Fitting Machining Equipment: | Sand-blasting machine,Electric bevelling machine, Bending machine, Pushing Machine, Press machine etc |

| Application: | Fabrication Industry Oil And Gas Industry Chemical Industry Nuclear Power Plant Water Pipeline Industry Natural Gas Industry |

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WPC | 0.35 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WP11 CL1 | 0.05-0.15 | 0.30-0.60 | 0.03 | 0.03 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

| WP11 CL2/3 | 0.05-0.20 | 0.30-0.80 | 0.04 | 0.04 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

| Pipe | PipeTee Fitting | Flanges | Valves | Bolts & Nuts |

|---|---|---|---|---|

| A106 Gr A | A234 Gr WPA Elbow | A105 | A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| A106 Gr B | ASTM A234 gr WPB Elbow | A105 | A216 Gr WCB | |

| A106 Gr C | A234 Gr WPC Elbow | A105 | A216 Gr WCB |

ASTM A420 WPL6 45 degree Elbow

Carbon Steel SA 420 WPL6 90 deg Elbow

ASTM A420 Buttweld 180 Degree Elbow

Carbon Steel WPL6 Long Radius Elbow

ASTM A420 Gr WPL6 Short Radius Elbow

LTCS A420 45 Deg SR Elbow

SA420 WPL6 degree 90 LR Elbow

A420 Gr 3D Elbow

| Tensile Requirements | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Tensile Strength, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% offset or 0.5% extension-under-load) | [415-585] | [485-655] | [415-585] | [520-690] |

| Yield Strength, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

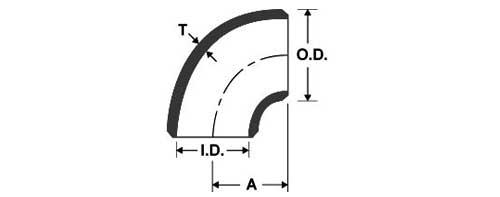

| NPS | OD | ID | Wall Thick. |

Center To End |

Pipe Sch |

Weight Pound |

| 1 | 1.32 | 1.05 | 0.133 | 1 | 40 | 0.25 |

| 1 1/4 | 1.66 | 1.38 | 0.14 | 1.25 | 40 | 0.39 |

| 1 1/2 | 1.9 | 1.61 | 0.145 | 1.5 | 40 | 0.53 |

| 2 | 2.38 | 2.07 | 0.154 | 2 | 40 | 0.97 |

| 2 1/2 | 2.88 | 2.47 | 0.203 | 2.5 | 40 | 2 |

| 3 | 3.5 | 3.07 | 0.216 | 3 | 40 | 3 |

| 3 1/2 | 4 | 3.55 | 0.226 | 3.5 | 40 | 4.3 |

| 4 | 4.5 | 4.03 | 0.237 | 4 | 40 | 6.1 |

| 5 | 5.56 | 5.05 | 0.258 | 5 | 40 | 9.7 |

| 6 | 6.63 | 6.07 | 0.28 | 6 | 40 | 16.7 |

| 8 | 8.63 | 7.98 | 0.322 | 8 | 40 | 32.4 |

| 10 | 10.75 | 10.02 | 0.365 | 10 | 40 | 56.3 |

| 12 | 12.75 | 12 | 0.375 | 12 | * | 79.4 |

| 14 | 14 | 13.25 | 0.375 | 14 | 30 | 104 |

| 16 | 16 | 15.25 | 0.375 | 16 | 30 | 129 |

| 18 | 18 | 17.25 | 0.375 | 18 | * | 163 |

| 20 | 20 | 19.25 | 0.375 | 20 | 20 | 210 |

| 24 | 24 | 23.25 | 0.375 | 24 | 20 | 297 |

| 30 | 30 | 29.25 | 0.375 | 30 | * | 480 |

| 36 | 36 | 35.25 | 0.375 | 36 | * | 692 |

| 42 | 42 | 41.25 | 0.375 | 42 | * | 967 |

| 48 | 48 | 47.25 | 0.375 | 48 | * | 1,340 |

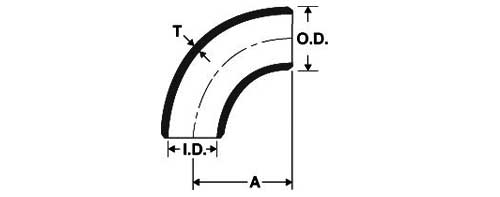

| NPS | OD | ID | Wall Thick. |

Center To End |

Pipe Sch |

Weight Pound |

| 1/2 | 0.84 | 0.622 | 0.109 | 1.5 | 40 | 0.16 |

| 3/4 | 1.05 | 0.824 | 0.113 | 1.5 | 40 | 0.17 |

| 1 | 1.32 | 1.049 | 0.133 | 1.5 | 40 | 0.4 |

| 1 1/4 | 1.66 | 1.38 | 0.14 | 1.88 | 40 | 0.55 |

| 1 1/2 | 1.9 | 1.61 | 0.145 | 2.25 | 40 | 0.8 |

| 2 | 2.38 | 2.07 | 0.154 | 3 | 40 | 1.6 |

| 2 1/2 | 2.88 | 2.47 | 0.203 | 3.75 | 40 | 3.2 |

| 3 | 3.5 | 3.07 | 0.216 | 4.5 | 40 | 4.8 |

| 3 1/2 | 4 | 3.55 | 0.226 | 5.25 | 40 | 6.6 |

| 4 | 4.5 | 4.03 | 0.237 | 6 | 40 | 8.9 |

| 5 | 5.56 | 5.05 | 0.258 | 7.5 | 40 | 15.1 |

| 6 | 6.62 | 6.07 | 0.28 | 9 | 40 | 24 |

| 8 | 8.62 | 7.98 | 0.322 | 12 | 40 | 47.8 |

| 10 | 10.75 | 10.02 | 0.365 | 15 | 40 | 83.4 |

| 12 | 12.75 | 12 | 0.375 | 18 | * | 123 |

| 14 | 14 | 13.25 | 0.375 | 21 | 30 | 155 |

| 16 | 16 | 15.25 | 0.375 | 24 | 30 | 206 |

| 18 | 18 | 17.25 | 0.375 | 27 | * | 262 |

| 20 | 20 | 19.25 | 0.375 | 30 | 20 | 324 |

| 24 | 24 | 23.25 | 0.375 | 36 | 20 | 466 |

| 30 | 30 | 29.25 | 0.375 | 45 | * | 720 |

| 36 | 36 | 35.25 | 0.375 | 54 | * | 1,039 |

| 42 | 42 | 41.25 | 0.375 | 63 | * | 1,420 |

| 48 | 48 | 47.25 | 0.375 | 72 | * | 2,000 |

| Sch | Size | Weight (Kilogram) |

|---|---|---|

| 1 1/4" | 1 1/4" | 0.5 |

| 1 1/2" | 1 1/2" | 0.8 |

| 2" | 2" | 1.4 |

| 2 1/2" | 2 1/2" | 2.7 |

| 3" | 3" | 4.2 |

| 8" | 8" | 20.9 |

| 4" | 4" | 7.9 |

| 1/2" | 1/2" | 0.1 |

| 3/4" | 3/4" | 0.1 |

| 2 1/2" | 2 1/2" | 1.3 |

| 1" | 1" | 0.2 |

| 1 1/4" | 1 1/4" | 0.3 |

| 1 1/2" | 1 1/2" | 0.4 |

| 2" | 2" | 0.7 |

| 4" | 4" | 4 |

| 10" | 10" | 37 |

| 12" | 12" | 54 |

| 5" | 5" | 3.3 |

| 1" | 1" | 0.1 |

| 3" | 3" | 2.1 |

| 1 1/4" | 1 1/4" | 0.2 |

| 2 1/2" | 2 1/2" | 0.7 |

| 1 1/2" | 1 1/2" | 0.2 |

| 2" | 2" | 0.4 |

| 6" | 6" | 10.4 |

| 4" | 4" | 2 |

| 6" | 6" | 5.1 |

| 8" | 8" | 10.3 |

| 5" | 5" | 6.7 |

| 3" | 3" | 1.1 |

| 10" | 10" | 18.3 |