-

-

send us mail

[email protected]

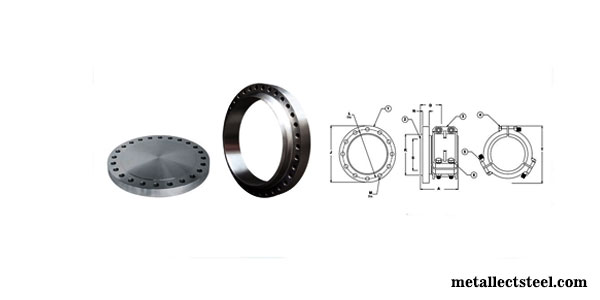

Typically, flanges produced under standard ASME B16.47 are made from materials that are either cast or forged. However, an exception permitted by the standard is that the blind variety of the ASME B16.47 Flange could be produced from a plate.

The ASME B16.47 standard encompasses materials, ASME B16 47 Series Dimensions, tolerances, marking, and testing for pipe flanges. Requirements and recommendations in the form of details regarding bolting and gaskets are also included in this standard. In addition, to the ASTM B16 47 Flange Pressure Ratings class 75, 150, 300, 400, 600, and 900, these flanges are produced in sizes NPS 26 through NPS 60.

A Reducing flange is a kind of specialty flanges which is most frequently used on projects that require the fitting together of pipes that have different sizes in a piping system. There are several types of ASME B16.47 Reducing Flange including weld neck reducing flanges, slip on reducing flanges as well as threaded reducing flanges.

Check The Market Price Before You Buy 2 Inch, WN, Forged, SCH-80, 300LBS, RF, ASTM A182 304L, ANSI B16.47 / ASME B16.47 Flange.

Both ASME B16.47 Series A And Series B Flanges define weld neck flanges as well as blind flanges constructed with a raised face. The main difference being that Series A in this standard defines ring type joint (RTJ) flanges between pressure rating Class 300 through Class 900 as opposed to Series B, which does not define RTJ flanges. Generally, Series A Stainless Steel ASME B16.47 Flange tends to be much expensive than series A on account of being thicker, heavier and stronger while being able to withstand higher external loads.

| Specification : | ASME B16.47 Flange |

| Connect Type Type: | LJF, LMF, SMF, RF, FF, RTJ. |

| ASA Flanges Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Coating Flanges Faces : | Zinc Plated, Oil Black Paint, Anti-rust Paint, Yellow Transparent, Cold and Hot Dip Galvanized |

| Application: | Fabrication Industry Oil And Gas Industry Natural Gas Industry Water Pipeline Industry Nuclear Power Plant Chemical Industry |

| ASME B16.47 Flange Standards : | BS10, JIS, MSS SP44, EN-1092, ASME B16.47 (Series A, Series B), PN, ISO, ASME B16.38, AWWA, DIN, GOST, UNI, ASME B16.5. |

| Design For Size: | ASME, EN, DIN, ASA, PN, JIS, ANSI, BS |

| Machining Equipment: | Pushing Machine, Bending machine, Electric bevelling machine, Press machine, Sand-blasting machine etc |

| Production Process: | Forged, Heat Treated and Machined |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Normal Pipe Size | Dimensions | Weight (Kilogram) | ||||

|---|---|---|---|---|---|---|

| NPS (In.) |

DN (millimeter) | FLANGES Outer Diameter Millimeter Millimeter |

FLANGES Thickness D millimeter |

SOW Socket Weld |

Weld Neck | Blind |

| 1/2 | 15 | 88.9 | 11.2 | 0.4 | 0.5 | 0.4 |

| 3/4 | 20 | 98.6 | 12.7 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 | 1 | 0.9 |

| 1 1/4 | 32 | 117.3 | 15.7 | 1 | 1.3 | 1.2 |

| 1 1/2 | 40 | 127 | 17.5 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.6 | 2.4 |

| 2 1/2 | 65 | 177.8 | 22.4 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/2 | 90 | 215.9 | 23.9 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 24 | 28.6 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 635 | 39.6 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 84.5 | 122.0 |

| 24 | 600 | 812.8 | 47.8 | 86.9 | 115 | 185.0 |

|

ASME B16.47 Flange Temperature |

||||||||

|

Flanges Tables |

-10° |

250° |

300° |

350° |

400° |

425° |

450° |

475° |

|

6 |

6 |

5.5 |

5 |

– |

– |

– |

– |

– |

|

10 |

10 |

9 |

8 |

7 |

6 |

– |

– |

– |

|

16 |

16 |

15 |

13 |

11 |

9 |

– |

– |

– |

|

25 |

25 |

24 |

21 |

17 |

14 |

12 |

9 |

6 |

|

40 |

40 |

38 |

33 |

28 |

23 |

20 |

15 |

10 |

|

64 |

64 |

61 |

53 |

44 |

36 |

32 |

24 |

16 |

|

100 |

100 |

95 |

83 |

70 |

57 |

50 |

37 |

25 |

|

160 |

160 |

152 |

132 |

112 |

92 |

80 |

60 |

40 |