-

-

send us mail

[email protected]

As opposed to higher carbon steel grades, mild steel is quite malleable, even when cold. Hence, along with having high tensile strength and impact strength properties, it can be easily formed into Mild Steel Fittings. When cold, carbon steel grades that have a higher content of carbon usually shatter or crack under stress. In order to improve its corrosion resistance properties or to make it long-lasting and rustproof, MS Pipe Fittings are often galvanised or coated with the right paint. In addition to the aforementioned properties, what makes Mild Steel Weld Fittings more attractive to many buyers is the fact that this alloy is relatively cheaper than most steels grades. Primarily used to change the direction of the flow, Mild Steel Buttweld Fittings produced under specification ANSI / ASME B16. 9.

Commonly used as a part of construction material, mild steel is very strong. The term mild steel is an indicator of its relatively low carbon content.

| Standard Specification : | Mild Steel Fittings |

| Coating Fitting Faces : | Yellow Transparent, Oil Black Paint, Cold and Hot Dip Galvanized, Zinc Plated, Anti-rust Paint |

| Fitting Machining Equipment: | Bending machine, Pushing Machine, Press machine, electric bevelling machine, Sand-blasting machine etc |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, MSS-SP-43 Type B Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, MSS-SP-43 Type b Fittings |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Application: | Chemical Industry Water Pipeline Industry Nuclear Power Plant Natural Gas Industry Fabrication Industry Oil And Gas Industry |

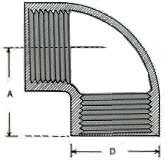

This fitting is a weldable pipe that permits permit branching off, a reduction in pipe size as well as an attachment for auxiliary equipment. Similar to buttweld fittings, a Mild Steel 90 Degree Elbow permits for change in the flow of direction by an angle of 90 degrees. As the name suggests, Mild Steel Threaded Fittings have internal threads that provide for a quick and easy connection method, especially for pipes whose bore size is small or where the nominal diameter of the pipe is NPS 2 or smaller.

| NPS in millimeter | A in millimeter | D in millimeter |

| 15 | 34 | 30 |

| 20 | 39 | 36 |

| 25 | 43 | 41 |

| 32 | 46 | 50 |

| 40 | 52 | 58 |

| 50 | 60 | 71 |

| 65 | 70 | 88 |

| 80 | 79 | 100 |

| 100 | 98 | 126 |

| 150 | 134 | 180 |

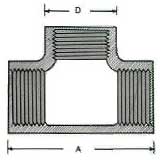

| NPS in millimeter | A in millimeter | D in millimeter |

| 15 | 64 | 30 |

| 20 | 70 | 36 |

| 25 | 79 | 41 |

| 32 | 92 | 51 |

| 40 | 100 | 58 |

| 50 | 117 | 71 |

| 65 | 140 | 88 |

| 80 | 157 | 100 |

| 100 | 195 | 126 |

| 150 | 264 | 180 |

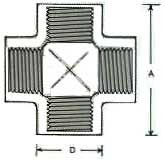

| NPS in millimeter | A in millimeter | D in millimeter |

| 15 | 64 | 30 |

| 20 | 67 | 35 |

| 25 | 77 | 41 |

| 32 | 90 | 51 |

| 40 | 102 | 58 |

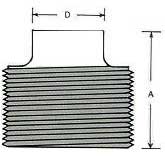

| NPS in millimeter | A in millimeter | D in millimeter |

| 15 | 24 | 13 |

| 20 | 27 | 15 |

| 25 | 31 | 19 |

| 32 | 35 | 24 |

| 40 | 37 | 27 |

| 50 | 45 | 33 |

| 65 | 45 | 34 |

| 80 | 45 | 38 |

| 100 | 51 | 46 |

Mild Steel Elbow

Mild Steel Tee

Mild Steel Reducer

Mild Steel End Cap

Mild Steel Stub End

Mild Steel Threaded Plug

Mild Steel Socket Weld Union

Mild Steel Cross

Mild Steel U Bend

Mild Steel Lateral Tee

| Products | Size |

| MS Cups | 1/2'' NB to 14'' NB |

| MS Stub Ends | 1/2'' NB to 14'' NB |

| MS Elbow | 1/2'' NB to 14'' NB |

| MS Reducers | 1'' NB to 14'' NB |

| MS Tees | 1'' NB to 14'' NB |

| MS Socket Weld | Upto 2'' NB |

| MS Nipples | Upto 4'' |

| MS Couplings | Upto 4''NB |

| Element | Content (%) |

| Iron, Fe | Balance |

| Chromium, Cr | 18-20 |

| Nickel, Ni | 11-15 |

| Molybdenum, Mo | 3-4 |

| Manganese, Mn | 2 |

| Silicon, Si | 1 |

| Phosphorous, P | 0.045 |

| Carbon, C | 0.03 |

| Sulfur, S | 0.03 |

| Properties | Metric | Imperial |

| Tensile strength | 595 MPa | 86300 psi |

| Yield strength | 260 MPa | 37700 psi |

| Modulus of elasticity | 200 GPa | 29000 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 55% | 55% |

| Hardness, Rockwell B | 85 | 85 |