-

-

send us mail

[email protected]

Galvanized fitting are also referred to as galvanized steel fitting, are divided into two categories hot-dip galvanizing and electro-galvanizing. While hot-dip galvanizing creates a thick layer, with the Galvanised Fittings having a uniform plating, in addition to the advantage of strong adhesion as well as long service life. Contrary to hot-dip galvanization, the cost of electroplating fitting is low, with the surface being not very smooth or even. In terms of its corrosion resistance properties, electroplating does not offer good corrosion resistance in comparison to hot-dip galvanized pipe fitting. Apart from being more durable, the 3000lb Galvanised Malleable Pipe Fittings will not get rapidly oxidized and will prevent the formation of white rust on the steel fittings. During the process of galvanization, both the inner and outside parts of the fitting are coated after being heated, which means the 1 Inch Galvanised Elbow Fittings have an extended service life due to increased protection against corrosive media in combination with its wear resistance characteristics.

Essentially galvanizing refers to coating the fittings with a thick layer of zinc.

Speaking of the manufacturing process of these fittings, since zinc has been used to plate the surface of the Galv Steel Pipe Fittings, the time initially required for the fittings to either undergo oiling or lacquering their surface has been omitted. Thus the manufacturing process is not only more convenient but is also a cost saving and time efficient one. Lastly, the Gi Tee Fittings do not easily freeze or crack even if they have been exposed to cold weather, which makes these fitting particularly well suited for the cold and freezing environment. Industries like oil and gas as well as petrochemical and petroleum refineries prefer using the Gi Pipe Fittings due to their properties.

| NPS in millimeter |

A in millimeter |

D in millimeter |

| 20x15 | 34 | 35 |

| 25x20 | 38 | 40 |

| 25x15 | 35 | 39 |

| 32x15 | 37 | 42 |

| 32x20 | 39 | 44 |

| 32x25 | 40 | 44 |

| 40x15 | 38 | 46 |

| 40x20 | 40 | 46 |

| 40x25 | 44 | 47 |

| 40x32 | 49 | 50 |

| 50x15 | 41 | 51 |

| 50x20 | 41 | 51 |

| 50x25 | 46 | 55 |

| 50x32 | 49 | 55 |

| 50x40 | 53 | 57 |

| 65x15 | 46 | 62 |

| 65x20 | 48 | 63 |

| 65x25 | 49 | 63 |

| 65x32 | 54 | 66 |

| 65x40 | 57 | 66 |

| 65x50 | 63 | 69 |

| 80x15 | 47 | 70 |

| 80x20 | 48 | 70 |

| 80x25 | 52 | 71 |

| 80x32 | 57 | 73 |

| 80x40 | 60 | 72 |

| 80x50 | 65 | 75 |

| 80x65 | 73 | 76 |

| 100x15 | 52 | 80 |

| 100x20 | 55 | 82 |

| 100x25 | 56 | 87 |

| 100x32 | 64 | 86 |

| 100x40 | 68 | 89 |

| 100x50 | 74 | 90 |

| 100x65 | 81 | 95 |

| 100x80 | 86 | 96 |

| NPS in millimeter |

A in millimeter |

B in millimeter |

C in millimeter |

D in millimeter |

| 20x15 | 33 | 30 | 30 | 30 |

| 25x15 | 33 | 30 | 37 | 42 |

| 25x20 | 35 | 36 | 37 | 42 |

| 32x15 | 36 | 30 | 42 | 51 |

| 32x20 | 37 | 35 | 44 | 51 |

| 32x25 | 40 | 42 | 45 | 51 |

| 40x15 | 38 | 30 | 47 | 58 |

| 40x20 | 40 | 36 | 47 | 58 |

| 40x25 | 43 | 42 | 48 | 58 |

| 40x32 | 47 | 51 | 48 | 58 |

| 50x15 | 38 | 30 | 52 | 71 |

| 50x20 | 41 | 36 | 53 | 71 |

| 50x25 | 45 | 41 | 54 | 71 |

| 50x32 | 45 | 51 | 55 | 71 |

| 50x40 | 52 | 58 | 58 | 71 |

| 65x50 | 62 | 71 | 56 | 88 |

| 80x15 | 50 | 30 | 67 | 100 |

| 80x20 | 51 | 36 | 71 | 100 |

| 80x25 | 51 | 41 | 71 | 100 |

| 80x32 | 56 | 51 | 72 | 100 |

| 80x40 | 58 | 58 | 71 | 100 |

| 80x50 | 64 | 71 | 71 | 100 |

| 80x65 | 72 | 88 | 72 | 100 |

| 100x15 | 52 | 30 | 82 | 126 |

| 100x20 | 53 | 36 | 82 | 126 |

| 100x25 | 57 | 41 | 83 | 126 |

| 100x32 | 62 | 51 | 87 | 126 |

| 100x40 | 65 | 58 | 87 | 126 |

| 100x50 | 72 | 71 | 89 | 126 |

| 100x65 | 78 | 88 | 89 | 126 |

| NPS in millimeter |

A in millimeter |

D in millimeter |

| 15 | 49 | 27 |

| 20 | 54 | 30 |

| 25 | 61 | 38 |

| 32 | 66 | 47 |

| 40 | 71 | 54 |

| 50 | 81 | 67 |

| 65 | 90 | 84 |

| 80 | 99 | 96 |

| 100 | 120 | 123 |

| 150 | 152 | 193 |

| NPS in millimeter |

A in millimeter |

B in millimeter |

D in millimeter |

| 15 | 53 | 26 | 30 |

| 20 | 58 | 55 | 36 |

| 25 | 68 | 64 | 41 |

| 32 | 73 | 75 | 51 |

| 40 | 74 | 84 | 58 |

| 50 | 79 | 95 | 71 |

| 65 | 89 | 113 | 88 |

| 80 | 99 | 131 | 100 |

| 100 | 110 | 153 | 127 |

| 150 | 146 | 223 | 182 |

| Standard Specification : | Galvanised Fittings |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | MSS-SP-43 Type A Fittings, MSS-SP-43 Type B Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, MSS-SP-43 Type b Fittings |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Application: | Natural Gas Industry Fabrication Industry Chemical Industry Water Pipeline Industry Nuclear Power Plant Oil And Gas Industry |

| Coating Fitting Faces : | Cold and Hot Dip Galvanized, Yellow Transparent, Oil Black Paint, Zinc Plated, Anti-rust Paint |

| Fitting Machining Equipment: | Press machine, electric bevelling machine, Bending machine, Pushing Machine, Sand-blasting machine etc |

| Galvanised Fittings Pressure Rating (psig) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | |||||||

| Allowable Stress (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | |||||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | |||

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | ||||

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | ||||

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | |||

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | ||||

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | ||||

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | |||

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | ||||

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | ||||

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | |||

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | ||||

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | ||||

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | |||

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | ||||

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | ||||

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | |||

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | ||||

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | ||||

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | |||

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | ||||

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | ||||

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | |||

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | ||||

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | ||||

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | |||

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | ||||

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | ||||

| Products | Size |

| Galvanised Cups | 1/2'' NB to 14'' NB |

| Galvanised Stub Ends | 1/2'' NB to 14'' NB |

| Galvanised Elbow | 1/2'' NB to 14'' NB |

| Galvanised Reducers | 1'' NB to 14'' NB |

| Galvanised Tees | 1'' NB to 14'' NB |

| Galvanised Socket Weld | Upto 2'' NB |

| Galvanised Nipples | Upto 4'' |

| Galvanised Couplings | Upto 4''NB |

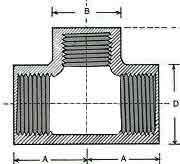

Galvanised Pipe Reducer

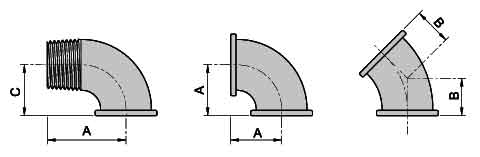

Galvanised Pipe Elbow

Galvanised Pipe Tee

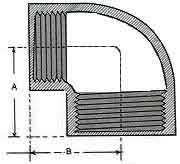

Galvanised Pipe End Cap

Galvanised Pipe U Bend

Galvanised Pipe Lateral Tee

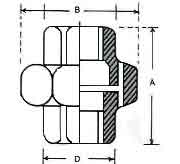

Galvanised Pipe Socket Weld Union

Galvanised Pipe Cross

Galvanised Pipe Stub End

Galvanised Pipe Threaded Plug

| Carbon | 0.20 |

|---|---|

| Manganese | 1.30 |

| Sulphur | 0.040 |

| phosphorus | 0.040 |