-

-

send us mail

[email protected]

The dimensions and tolerances used in the production of stainless steel fittings are covered by specification ASME B16.9. In addition, the specification also takes into consideration other parameters such as ratings, testing, and markings for wrought type Stainless Steel Buttweld Pipe Fittings produced in a factory. Usually, these factory made buttwelding fittings are produced in sizes that range between NPS 1.2 through NPS 48. One of the most commonly used stainless steel fittings belongs to the austenitic category. There are several benefits of using austenitic stainless steels. Firstly, the corrosion resistance properties of Austenitic SS Fittings are much higher than either martensitic or ferritic stainless steels classes.

Moreover, depending on the application for which these fittings are to be used, Stainless Steel Fittings Manufacturers In India use customized alloys.

For instance, if welding is one of the important requirements of the application, the manufacturer could use any version of low carbon containing grade austenitic stainless steels such as grade 316L or grade 304L. On the other hand, if a buyer states high tensile strength is of utmost importance, then the higher carbon version like grade 316H or grade 310H etc could be used to produce ASME B16.9 SS Welded Pipe Fittings. In addition to altering the content of carbon, manufacturers also have the option of controlling the contents of nitrogen and titanium amongst others, to make special alloyed Stainless Steel Seamless Pipe Fittings such as grade 316Ti or Alloy 317LMN. However, in many instances, the buyer also has the choice to dual certify these fitting. Which means grade 316, if made with increased carbon content could be dually certified as grade 316/316H Stainless Steel Buttweld Elbow.

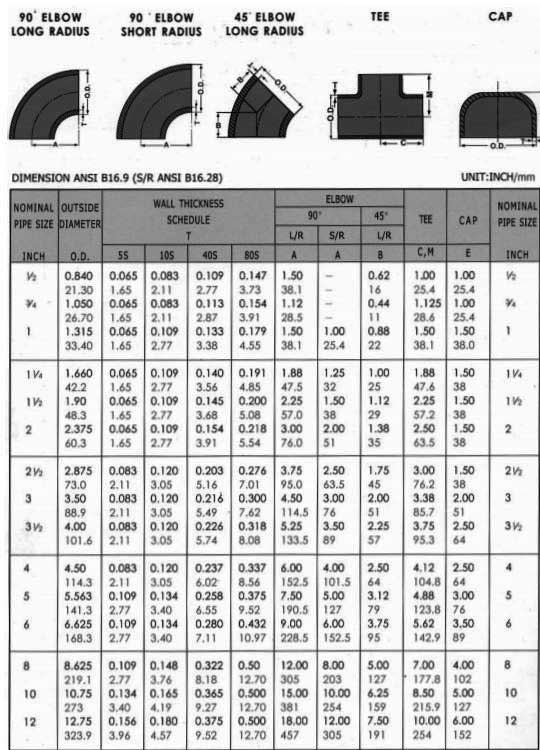

| Standard Specification : | Stainless Steel Buttweld Pipe Fittings |

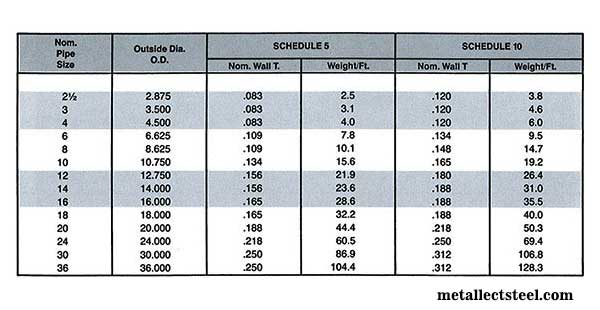

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, MSS-SP-43 Type b Fittings, MSS-SP-43 Type B Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, JIS B2313 Fittings |

| Stainless Steel Fittings Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Coating Flange Faces : | Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated |

| Fitting Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine, Press machine, electric bevelling machine etc |

| Rating Pressure: | Check Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Application: | Oil And Gas Industry Nuclear Power Plant Natural Gas Industry Chemical Industry Fabrication Industry Water Pipeline Industry |

| Pressure Rating (psig) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| SS 100 | SS 200 | SS 300 | SS 400 | SS 500 | SS 600 | SS 650 | SS 700 | SS 750 | ||||

| Allowable Stress (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

|

Ni

|

8 – 11

|

8 – 11

|

8 – 11

|

|

Fe

|

Balance

|

||

|

Cr

|

18 – 20

|

18 – 20

|

18 – 20

|

|

C

|

0.08 maximum

|

0.08 maximum

|

0.035 maximum

|

|

Si

|

0.75 maximum

|

0.75 maximum

|

0.75 maximum

|

|

Mn

|

2 maximum

|

2 maximum

|

2 maximum

|

|

P

|

0.040 maximum

|

0.040 maximum

|

0.040 maximum

|

|

S

|

0.030 maximum

|

0.030 maximum

|

0.030 maximum

|

|

N

|

0.10 – 0.16

|

0.10 – 0.16

|

|

| NPS | OD | 90 Degree Elbow | 45 Degree Elbow | 180 Degree Returns | ||||

|---|---|---|---|---|---|---|---|---|

|

(in.)

|

LR

|

SR

|

LR

|

LR

|

||||

|

(millimeter)

|

(in.)

|

Center to Face

(in.) |

Center to Face

(in.) |

Center to Face

(in.) |

Radius

(in.) |

Center to Center

(in.) |

Back to face

(in.) |

|

|

1/2

|

21.3

|

0.840

|

1 1/2

|

–

|

5/8

|

2

|

1 7/8

|

|

|

3/4

|

26.7

|

1.050

|

1 1/8

|

–

|

7/16

|

2 1/4

|

1 11/16

|

|

|

1

|

33.4

|

1.315

|

1 1/2

|

1

|

7/8

|

3

|

2 3/16

|

|

|

1 1/4

|

42.2

|

1.660

|

1 7/8

|

1 1/4

|

1

|

3 3/4

|

2 3/4

|

|

|

1 1/2

|

48.3

|

1.900

|

2 1/4

|

1 1/2

|

1 1/8

|

3

|

4 1/2

|

3 1/4

|

|

2

|

60.3

|

2.375

|

3

|

2

|

1 3/8

|

4

|

6

|

4 3/16

|

|

2 1/2

|

73.0

|

2.875

|

3 3/4

|

2 1/2

|

1 3/4

|

5

|

7 1/2

|

5 3/16

|

|

3

|

88.9

|

3.500

|

4 1/2

|

3

|

2

|

6

|

9

|

6 1/4

|

|

3 1/2

|

101.6

|

4.000

|

5 1/4

|

3 1/2

|

2 1/4

|

7

|

10 1/2

|

7 1/4

|

|

4

|

114.3

|

4.500

|

6

|

4

|

2 1/2

|

8

|

12

|

8 1/4

|

|

5

|

141.3

|

5.563

|

7 1/2

|

5

|

3 1/8

|

10

|

15

|

10 5/16

|

|

6

|

168.3

|

6.625

|

9

|

6

|

3 3/4

|

12

|

18

|

12 5/16

|

|

8

|

219.1

|

8.625

|

12

|

8

|

5

|

12

|

24

|

16 5/16

|

|

10

|

273.1

|

10.750

|

15

|

10

|

6 1/4

|

15

|

30

|

20 3/8

|

|

12

|

323.9

|

12.750

|

18

|

12

|

7 1/2

|

18

|

36

|

24 3/8

|

| Density | 8.0 g/cm3 |

| Melting Point | 1400 °C (2550 °F) |

| Tensile St. | Psi – 75000 , MPa – 515 |

| Yield St. (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Hs Code | Description | Number Of Shipments |

|---|---|---|

| 7307 | Tube Or Pipe Fitting (Half, Full Couplings, 45, 90, 180, Elbows,) | |

| 73072900 | Other | 11954 |

| 73079990 | Other | 1350 |

| 73072200 | NPT Elbows, Sleeves And Bends | 482 |

| 73072300 | BW Fitting | 384 |

| 73079190 | Other |