-

-

send us mail

[email protected]

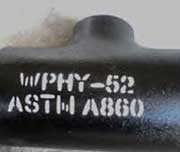

The full form of WPHY is Wrought Pipe or Plate High yield, which mentions a grade in the form of a number. The number is indicative of its minimum yield strength in 1000’s psi. For the said ASTM A860 WPHY 52 Fittings, the minimum yield strength is about 52000 PSI. The high strength material is a low alloy steel grade, designed to withstand high stress situations like those seen during the transmission of media across in the oil and gas industry. CS Gr A860 WPHY 52 Seamless Butt Weld Fittings have to be heat treated in order to achieve optimum tensile strength properties. The high strength obtained by these seamless or welded Carbon Steel WPHY 52 pipe Fittings could be increased by subjecting the material through processes such as normalizing, quenching, and tempering or stress relieving.

ASTM A860 WPHY 52 Fittings

Carbon Steel A860 Gr WPHY 52 Elbow

ASME B16.11 Buttweld WPHY 52 Reducer

The oil and gas industry exclusively use High yield fittings.

| Fittings Grade | C | Mn | S | P | Si | Ni | Cr | Mo | Cu | Ti | V | Cb |

| A860 WPHY 52 Fitting | 0.20 | 1.00-1.45 | 0.03 | 0.01 | 0.15-0.40 | 0.50 | 0.30 | 0.25 | 0.35 | 0.05 | 0.10 | 0.06 |

| Fittings Element | Tensile Strength | Elongation | Yield Strength (0.2%Offset) |

| WPHY 52 | 515-690 | 28 % | 66 |

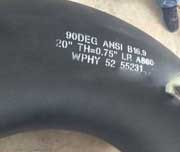

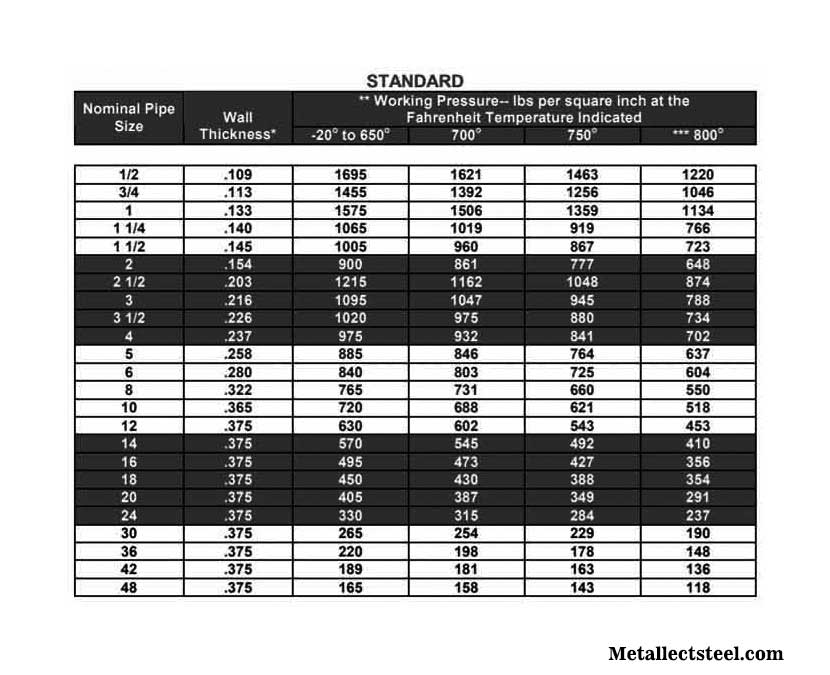

Along with conforming to the testing methods, chemistry and mechanical properties, the MSS-SP75 WPHY 52 Stub End is a fitting that conforms to the tolerances, dimensions, sizes as well. Properties such as the yield strength and tensile strength, notch toughness, elongation, in addition to the hardness of the Carbon Steel A860 gr WPHY 52 Elbow are required to conform to the specification. Although a hydrostatic test is not required to be administered to the Buttweld WPHY 52 Reducer.

| Standard Specification : | ASTM A860 WPHY 52 Fittings |

| Coating Fitting Faces : | Cold and Hot Dip Galvanized, Anti-rust Paint, Zinc Plated, Oil Black Paint, Yellow Transparent |

| Fitting Machining Equipment: | Electric bevelling machine, Sand-blasting machine, Press machine, Bending machine, Pushing Machine etc |

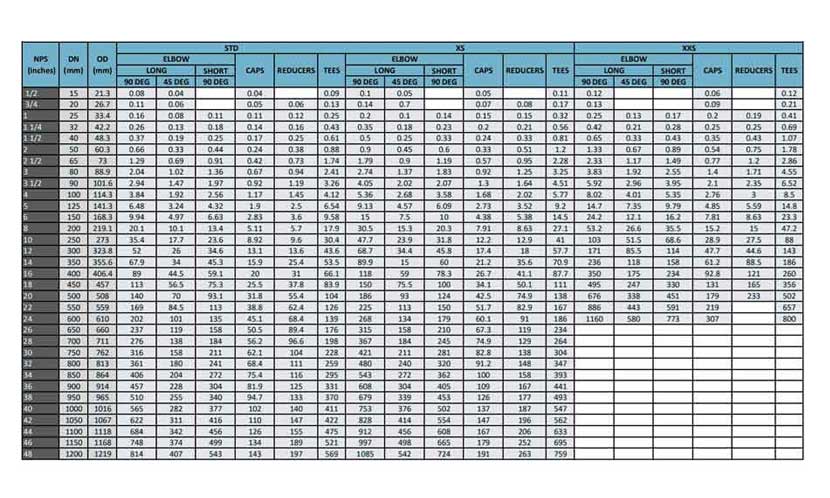

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Thickness: | View Our Thickness: Schedule 5S, Schedule 10, Schedule 20, Schedule 10, Schedule 20, Schedule 30, Schedule TD, Schedule 40, Schedule 60, XS, Schedule 80, Schedule 100, Schedule 120, Schedule 140, Schedule 160. |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Standard: | JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type b Fittings, MSS-SP-43 Type A Fittings, JIS B2312 Fittings, ANSI B16.28 Fittings, MSS-SP-43 Type B Fittings |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Application: | Chemical Industry Nuclear Power Plant Natural Gas Industry Fabrication Industry Oil And Gas Industry Water Pipeline Industry |

Carbon Steel A860 WPHY 52 Weld Lateral Tee

High Yield Carbon Steel A860 52 End Cap

ASTM A860 Carbon Steel WPHY 52 Reducing Tee

ASTM A860 High Yield Gr WPHY 52 Stub Ends

Buttweld-52 Concentric Reducer

MSS SP 75 WPHY 52 Eccentric Reducer

ASTM A860 Gr 52 45 Degree Elbow

Carbon Steel MSS SP75 52 90 Deg Elbow

A860 Carbon Steel WPHY-52 Equal Tee

A860 Gr 52 180 Deg Elbow

WPHY 52 BW Cross Fitting

MSS SP 75 WPHY 52 Material

ASTM A860 API 5L X52 elbow manufacturer

4. Buttweld WPHY-52 SMLS CAP

MSS SP 75 52 cap

Cap Pipe fittings

2. Carbon Steel MSS SP75 52 Tee

Carbon Steel A860 WPHY 52 Weld Reducing Tee

High Yield Carbon Steel A860 WPHY 52 Tee

3.ASTM A860 MSS SP 75 52 Reducer

WT: sch40/ std/ sch80/ thick-wall

Carbon Steel Grade WPHY 52 Pipe Concentric

A860 WPHY 52 Eccentric Reducer

MSS SP 75 A860 WPHY 52 Con/ Ecc Reducer

5. A860 Carbon Steel-WPHY 52 Stubend

A860 WPHY 52 Stubend

these Material ASTM A520 WPL6 Buttweld are known for accurate dimension, corrosion resistance and durability.

A860 Gr WPHY 52 Short Stubend

A860 WPHY 52 BW Long Stubend