-

-

send us mail

[email protected]

Grade UNS S31803 is termed as a duplex class due to its mixed Austenitic-ferritic microstructure. Duplex stainless steel alloys have an equal proportion of both austenite and ferrite, which is why Duplex Steel Fittings exhibit properties prominent to both classes. Duplex Steel Buttweld Fittings demonstrate better localized corrosion resistance in comparison to both grade 316L and 317L. Hence these duplex steel fittings are used in applications involving several key industrial fields such as chemical plants, seawater pump, seawater desalination plant, and so on. Werkstoff No 1.4462 Duplex Steel Pipe Fittings have a high resistance to intergranular corrosion, especially in chloride and sulphide containing environments. Usually, a regular steels grade would be susceptible to getting degraded in these conditions, unlike Duplex Stainless Steel Fittings, which exhibit very high resistance to stress related corrosion cracking.

Two of the most important characteristics of duplex grade is its superior corrosion resistance as well as high tensile strength.

UNS S31803 Duplex Steel Elbow fittings in most cases, tend to be tougher when compared to ferritic stainless steel. Whereas the mechanical strengths of duplex stainless steel fittings can in some cases for e.g. UNS S31803 could be as much as two times more than that of conventional austenitic stainless steels. The high chromium content present in the alloy is what protects the Duplex Steel Forged Fittings against corrosion, generally causes embrittlement at temperatures exceeding 300°C.

| Standard Specification : | Duplex Steel Fittings |

| Coating Fitting Faces : | Cold and Hot Dip Galvanized, Yellow Transparent, Oil Black Paint, Zinc Plated, Anti-rust Paint |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Application: | Nuclear Power Plant Water Pipeline Industry Chemical Industry Oil And Gas Industry Fabrication Industry Natural Gas Industry |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

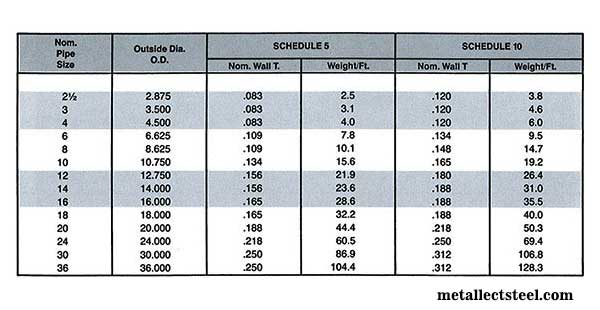

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Fitting Machining Equipment: | Press machine, electric bevelling machine, Bending machine, Pushing Machine, Sand-blasting machine etc |

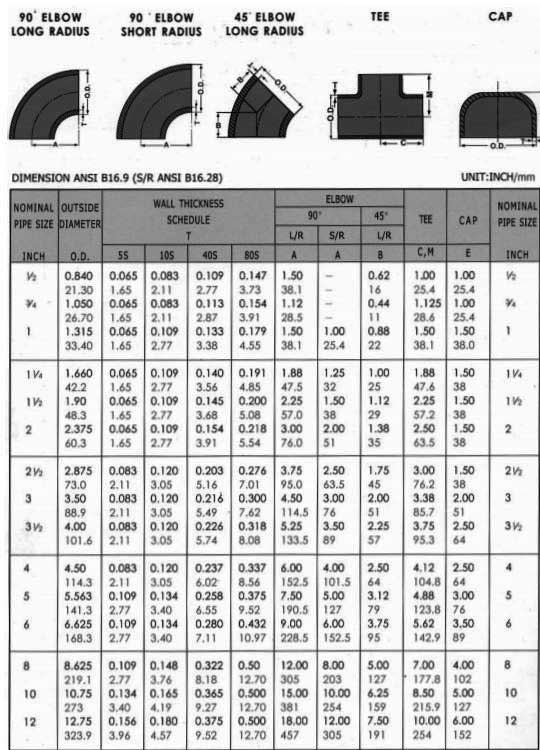

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | MSS-SP-43 Type B Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, MSS-SP-43 Type b Fittings |

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

Duplex Steel Buttweld Stub End

Duplex Steel Plug

Duplex Steel Forged Socket Weld Union

Werkstoff No 1.4462 Cross

Duplex UNS S31803 Elbow

Duplex UNS S32205 Tee

Duplex 2205 Seamless Reducer

Duplex End Cap

Duplex Stainless U Bend

Duplex Steel Lateral Tee

| Grade | S31803 |

|---|---|

| C | 0.030 maximum |

| Mn | 2.00 maximum |

| Si | 1.00 maximum |

| P | 0.030 maximum |

| S | 0.020 maximum |

| Cr | 22.0 – 23.0 |

| Mo | 3.0 – 3.5 |

| Ni | 4.50 – 6.50 |

| N | 0.14 – 0.20 |

| Fe | 63.72 min |

| Gr. | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

| Pressure Rating (psig) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Schedule. | OD (inch) |

Wall Thick. (in) |

Temperature | ||||||||

| Duplex Steel 100 Fitting | Duplex Steel 200 Fitting | Duplex Steel 300 Fitting | Duplex Steel 400 Fitting | Duplex Steel 500 Fitting | ||||||||

| Allowable Stress (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | ||||||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | ||||

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | |||||

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | |||||

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | ||||

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | |||||

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | |||||

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | ||||

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | |||||

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | |||||

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | ||||

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | |||||

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | |||||

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | ||||

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | |||||

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | |||||

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | ||||

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | |||||

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | |||||

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | ||||

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | |||||

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | |||||

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | ||||

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | |||||

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | |||||

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | ||||

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | |||||

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | |||||