-

-

send us mail

[email protected]

One of the main reasons why Cast Iron Fittings are considered for several industrial uses is because the metal offers many engineering properties. Hence these fittings are utilized in many ways such as for sanitary fittings, rail chairs, etc. Since the Ci Pipe Fittings exhibit good corrosion resistance properties, these fittings can be used in conjunction with pipes carrying water. With a melting point of about 1250C and a specific gravity value of 7.5, Cast Iron Flanges are used to connect pumps, valves, pipes as well as other equipment to form a system that does not require magnetic properties. While the metal has a tensile strength value of about 150 N/mm2, these fittings are good in compression as the Cast Iron Blind Flanges have a compressive strength of around 600 N/mm2. However, most manufacturers do not recommend using this metal for forging work due to its lack of plasticity.

The manufacturing process of Cast iron involves remelting of pig-iron with coke and limestone. Pig iron or as also referred to as impure iron is obtained from the iron ore.

| Specification : | Cast Iron Fittings |

| Production Process: | Heat Treated, Machined, Forged |

| Coating Flange Faces : | Zinc Plated, Yellow Transparent, Anti-rust Paint, Cold and Hot Dip Galvanized, Oil Black Paint |

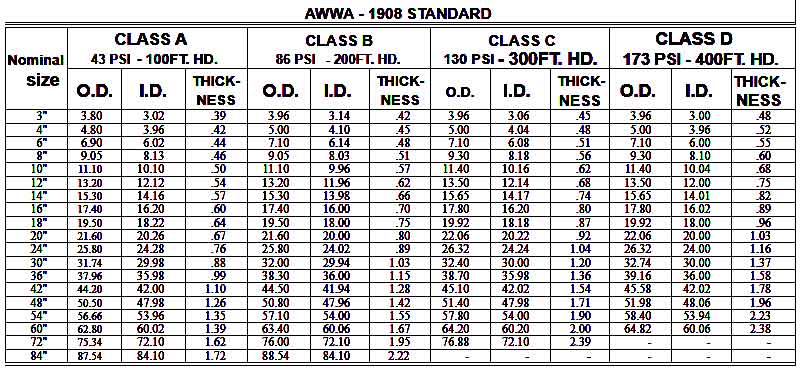

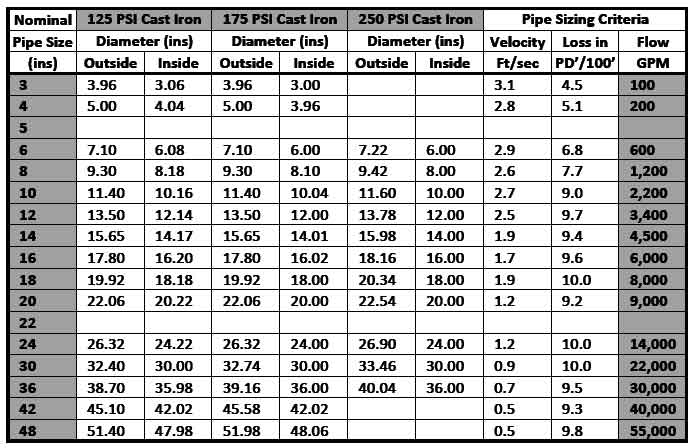

| Standards: | GOST Flange, UNI Flange, AWWA Flange, MSS SP44 Flange, ASME B16.5 Flange, ASME B16.38 Flange, EN-1092 Flange, BS10 Flange, DIN Flange, PN Flange, JIS Flange, ISO Flange, ASME B16.47 (Series A, Series B) |

| Pressure Rating Table: | Class 150 LBS Fittings, Class 300 LBS Fittings, Class 600 LBS Fittings, Class 900 LBS Fittings, Class 1500 LBS Fittings, Class 2500 LBS Fittings |

| Common Types of Flange : | Flange 150 LB WNRF Class 300 RTJ 600# BLRF Class 900 SORF |

| Supporting Flange Material: | Gasket, Flange Bolts, Ring Joint |

| Application: | Water Pipeline Industry Nuclear Power Plant Natural Gas Industry Oil And Gas Industry Chemical Industry Fabrication Industry |

| Design For Size: | EN Fittings, ASA Fittings, ASME Fittings, BS Fittings, DIN Fittings, JIS Fittings, ANSI Fittings, PN Fittings |

| Flange Machining Equipment: | Press machine, Bending machine, Sand-blasting machine, Pushing Machine, electric bevelling machine etc |

| Connect Type: | LJF, RF, FF, LMF, SMF, RTJ |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

Generally, Cast Iron Floor Flanges are used to connect either a threaded rigid conduit or an IMC conduit to flat surfaces. Therefore a floor flange proves to be very useful for hanging security cameras, smoke detectors or fire alarm signals/strobes as well as other low-voltage and electronic signalling devices from ceilings. Reckoned to be one of the oldest fittings, the Cast Iron Threaded Fittings aid in forging connections with pipes of smaller diameter, wherein the diameter measures between NPS 2 or smaller.

| Cast Iron Flanges - ASME/ANSI 125 lb | ||||

|---|---|---|---|---|

| PNS (in.) | OD (in.) | No. of Bolt Holes | Bolt Hole Dia. (in.) | Bolt Circle (in.) |

| 1 | 4-1/4 | 4 | 5/8 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 5/8 | 3-1/2 |

| 1-1/2 | 5 | 4 | 5/8 | 3-7/8 |

| 2 | 6 | 4 | 3/4 | 4-3/4 |

| 2-1/2 | 7 | 4 | 3/4 | 5-1/2 |

| 3 | 7-1/2 | 4 | 3/4 | 6 |

| 3-1/2 | 8-1/2 | 8 | 3/4 | 7 |

| 4 | 9 | 8 | 3/4 | 7-1/2 |

| 5 | 10 | 8 | 7/8 | 8-1/2 |

| 6 | 11 | 8 | 7/8 | 9-1/2 |

| 8 | 13-1/2 | 8 | 7/8 | 11-3/4 |

| 10 | 16 | 12 | 1 | 14-1/4 |

| 12 | 19 | 12 | 1 | 17 |

| 14 | 21 | 12 | 1-1/8 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1-1/8 | 21-1/4 |

| 18 | 25 | 16 | 1-1/4 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/4 | 25 |

| 24 | 32 | 20 | 1-3/8 | 29-1/2 |

| 30 | 38-3/4 | 28 | 1-3/8 | 36 |

| 36 | 46 | 32 | 1-5/8 | 42-3/4 |

| 42 | 53 | 36 | 1-5/8 | 49-1/2 |

| 48 | 59-1/2 | 44 | 1-5/8 | 56 |

| 54 | 66-1/4 | 44 | 2 | 62-3/4 |

| 60 | 73 | 52 | 2 | 69-1/4 |

| Cast Iron Flanges - ASME/ANSI 250 lb | ||||

|---|---|---|---|---|

| NPS (in.) | OD (in.) | No. of Bolt Holes | Bolt Hole Dia. (in.) | Bolt Circle (in.) |

| 1 | 4-7/8 | 4 | 3/4 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 3/4 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 7/8 | 4-1/2 |

| 2 | 6-1/2 | 8 | 3/4 | 5 |

| 2-1/2 | 7-1/2 | 8 | 7/8 | 5-7/8 |

| 3 | 8-1/4 | 8 | 7/8 | 6-5/8 |

| 3-1/2 | 9 | 8 | 7/8 | 7-1/4 |

| 4 | 10 | 8 | 7/8 | 7-7/8 |

| 5 | 11 | 8 | 7/8 | 9-1/4 |

| 6 | 12-1/2 | 12 | 7/8 | 10-5/8 |

| 8 | 15 | 12 | 1 | 13 |

| 10 | 17-1/2 | 16 | 1-1/8 | 15-1/4 |

| 12 | 20-1/2 | 16 | 1-1/4 | 17-3/4 |

| 14 | 23 | 20 | 1-1/4 | 20-1/4 |

| 16 | 25-1/2 | 20 | 1-3/8 | 22-1/2 |

| 18 | 28 | 24 | 1-3/8 | 24-3/4 |

| 20 | 30-1/2 | 24 | 1-3/8 | 27 |

| 24 | 36 | 24 | 1-5/8 | 32 |

| 30 | 43 | 28 | 2 | 39-1/4 |

| 36 | 50 | 32 | 2-1/4 | 46 |

| 42 | 57 | 36 | 2-1/4 | 52-3/4 |

| 48 | 65 | 40 | 2-1/4 | 60-3/4 |

Cast Iron Reducer

Cast Iron Elbow

Cast Iron Tee

Cast Iron End Cap

Cast Iron U Bend

Cast Iron Lateral Tee

Cast Iron Socket Weld Flanges

Cast Iron Threaded Flanges

Cast Iron Floor Flanges

Cast Iron Puddle Flanges

| Cast Iron Fittings Pressure Rating | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| Cast Iron 100 Fittings | Cast Iron 200 Fittings | Cast Iron 300 Fittings | Cast Iron 400 Fittings | Cast Iron 500 Fittings | Cast Iron 600 Fittings | |||||||

| (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | |||||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | |||

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | ||||

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | ||||

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | |||

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | ||||

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | ||||

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | |||

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | ||||

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | ||||

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | |||

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | ||||

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | ||||

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | |||

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | ||||

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | ||||

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | |||

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | ||||

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | ||||

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | |||

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | ||||

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | ||||

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | |||

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | ||||

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | ||||

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | |||

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | ||||

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | ||||