-

-

send us mail

[email protected]

Often, the DIN standard will accompany the Nominal pressure rating, which in the instance of DIN 2573 PN6 Flange is approx 6 bar. While flanges have many functions, the type of flanges used will determine its use in any application. Usually, a DIN 2573 PN6 Blind Flange is used to shut-off or seal off a valve in a piping system, thus effectively shutting off the flow of media across. This DIN standard covers pressure-temperature ratings, marking, materials, DIN 2573 Standard Flange Dimension, tolerances, testing, along with various methods of designated openings for pipe flanges as well as for flanged fittings.

Most countries across Europe install flanges in accordance with standards such as the DIN or EN.

To manufacture DIN 2573 PN 6 dn 100 Flange, materials such as Inconel, Incoloy, Monel, Nickel, Hastalloy, Titanium, Stainless Steel, Carbon Steel, Duplex Steel as well as Alloy Steel are used by manufacturers make good quality flanges. However, the most commonly used alloys amongst them used for the production of DIN 2573 Flange is stainless steel and carbon steel, If required, buyers can choose from any one of the following surface treatments ie. Transparent/ Yellow/ Black Anti-rust Paint, Zinc, Anti-rust Oil, Hot dipped Galvanization to be used on the Stainless Steel 2573 PN6 Plate Flange.

| Specification : | DIN 2573 PN6 Flange |

| Coating Flanges Faces : | Zinc Plated, Oil Black Paint, Yellow Transparent, Cold and Hot Dip Galvanized, Anti-rust Paint |

| Design For Size: | DIN, EN, ASA, PN, JIS, BS, ANSI, ASME |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Application: | Natural Gas Industry Nuclear Power Plant Chemical Industry Oil And Gas Industry Water Pipeline Industry Fabrication Industry |

| Supporting Flanges Material: | Flanges Bolts, Gasket, Ring Joint |

| Connect Type Type: | FF, RTJ, SMF, LMF, RF, LJF |

| Common Types of Flanges Dimensions: | Class 150 RTJ Flanges 300 LB WNRF Class 900 SORF 1500# BLRF Class 2500 BLRF |

| Production Process: | Forged, Heat Treated and Machined |

| Standard : | ASME B16.38 Flange, DIN Flange, ISO Flange, JIS Flange, PN Flange, MSS SP44 Flange, EN-1092 Flange, BS10 Flange, ASME B16.47 (Series A, Series B) Flange, UNI Flange, ASME B16.5 Flange, AWWA Flange, DIN Flange, GOST Flange |

| Machining Equipment: | Bending machine, Sand-blasting machine, Press machine, Pushing Machine, Electric bevelling machine etc |

DIN 2573 Standard Flange

DIN 2573 PN6 Plate Flange

Stainless Steel DIN 2573 PN6 Flange

DIN 2573 PN 6 dn 100 Flange

DIN 2573 PN6 Blind Flange

Alloy Steel DIN 2573 Flanges PN6

DIN 2573 PN6 Slip On Flange

Flange DIN 2573 PN6 Material

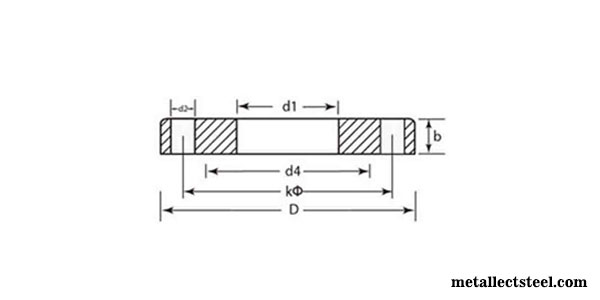

| NPS | Flanges | Screws | Weight (7,85 Kg/dm3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rated Diam. |

d1 | d5 | D | b | c | k | Holes | Thread | d2 | Kg | |

| ISO Series 1 | DIN Series 2 | ||||||||||

| 15 | - | 20 | 21 | 80 | 12 | 5 | 55 | 4 | M 10 | 11 | 0,41 |

| 21,3 | - | 22 | |||||||||

| 20 | - | 25 | 26 | 90 | 14 | 5 | 65 | 4 | M 10 | 11 | 0,60 |

| 26,9 | - | 27,6 | |||||||||

| 25 | - | 30 | 31 | 100 | 14 | 5 | 75 | 4 | M 10 | 11 | 0,74 |

| 33,7 | - | 34,4 | |||||||||

| 32 | - | 38 | 39 | 120 | 16 | 5 | 90 | 4 | M 12 | 14 | 1,19 |

| 42,4 | - | 43,1 | |||||||||

| 40 | - | 44,5 | 45,5 | 130 | 16 | 5 | 100 | 4 | M 12 | 14 | 1,39 |

| 48,3 | - | 49 | |||||||||

| 50 | - | 57 | 58,1 | 140 | 16 | 6 | 110 | 4 | M 12 | 14 | 1,53 |

| 60,3 | - | 61,1 | |||||||||

| 65 | 76,1 | - | 77,1 | 160 | 16 | 6 | 130 | 4 | M 12 | 14 | 1,89 |

| 80 | 88,9 | - | 90,3 | 190 | 18 | 7 | 150 | 4 | M 16 | 18 | 2,98 |

| 100 | - | 108 | 109,6 | 210 | 18 | 7 | 170 | 4 | M 16 | 18 | 3,46 |

| 114,3 | - | 115,9 | |||||||||

| 125 | - | 133 | 134,8 | 240 | 20 | 7 | 200 | 8 | M 16 | 18 | 4,60 |

| 139,7 | - | 141,6 | |||||||||

| 150 | - | 159 | 161,1 | 265 | 20 | 7 | 225 | 8 | M 16 | 18 | 5,22 |

| 168,3 | - | 170,5 | |||||||||

| 200 | 219,1 | - | 221,8 | 320 | 22 | 7 | 280 | 8 | M 16 | 18 | 7,15 |

| 250 | - | 267 | 270,2 | 375 | 24 | 7 | 335 | 12 | M 16 | 18 | 9,61 |

| 273 | - | 276,2 | |||||||||

| 300 | 323,9 | - | 327,6 | 440 | 24 | 7 | 395 | 12 | M 20 | 22 | 12,60 |

| 350 | 355,6 | - | 359,7 | 490 | 26 | 7 | 445 | 12 | M 20 | 22 | 15,60 |

| - | 368 | 372,2 | |||||||||

| 400 | 406,4 | - | 411 | 540 | 28 | 7 | 495 | 16 | M 20 | 22 | 18,40 |

| - | 419 | 423,7 | |||||||||

| (450)* | 457 | - | 462,5 | 595 | 30 | 7 | 550 | 16 | M 20 | 22 | 21,40 |

| 500 | 508 | - | 531,6 | 645 | 30 | 7 | 600 | 20 | M 20 | 22 | 24,60 |

| Temperature (in F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test (psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

| NPS NPS (inch) |

|||||

|---|---|---|---|---|---|

| Diammeter of Flange (inch) |

No. of Bolts |

Diammeter of Bolts (inch) |

Diammeter of Bolt Holes (inch) |

Bolt Circle (inch) |

|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |