-

-

send us mail

[email protected]

Those components, including fittings which have been manufactured as per the norms and guidelines of Indian Boiler Regulations or shortened as IBR are popularly referred to as IBR pipe fittings. These IBR Pipe Fittings are known to possess great toughness and quality as compared to conventionally manufactured pipe fittings. Regularly these pipes are produced with a flawless and rustproof finish. In fact, the exemplary mechanical strength properties of the IBR Fittings is what aids their sustenance in piping systems that are accustomed to elevated pressures even if the IBR Approved Pipe Fittings have been exposed to temperatures at an elevated range.

The inspection performed on the IBR Approved Elbow by the agency fulfils both the legal compliance as well as the safety assurance of these fittings.

Since the use of these fittings is widespread over different industries, various alloy grades are used as materials in the construction of these fittings. Depending on the alloy grade selected, by both the buyer and IBR Approved Fittings Manufacturer, these fittings exhibit immunity to a lot of different kinds of chemicals, solvents, and acids. This is also because the Indian Boiler Regulation defines specific rules which the manufacturer needs to follow while designing and constructing the product as well as inspecting and using approved test methods on components like the IBR Approved Reducer. Another important aspect of the fittings is the inspection of these fittings by a government certified third party agency.

| Standard Specification : | IBR Pipe Fittings |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Application: | Oil And Gas Industry Water Pipeline Industry Fabrication Industry Chemical Industry Nuclear Power Plant Natural Gas Industry |

| Coating Fitting Faces : | Oil Black Paint, Cold and Hot Dip Galvanized, Zinc Plated, Anti-rust Paint, Yellow Transparent |

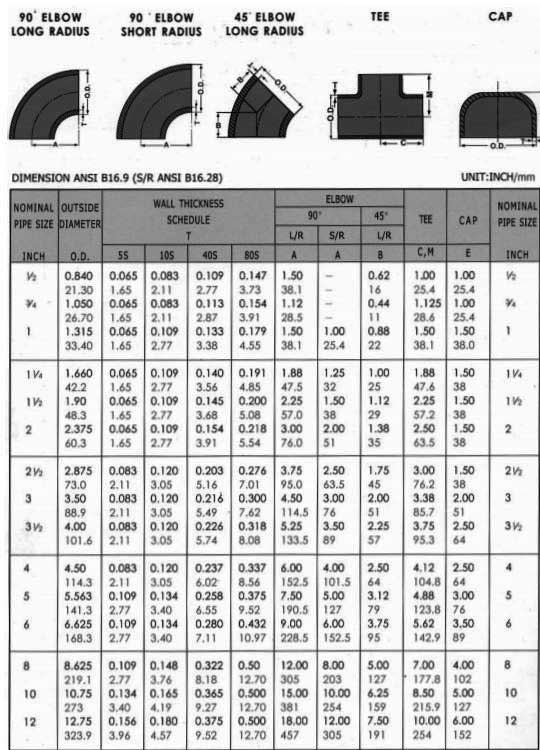

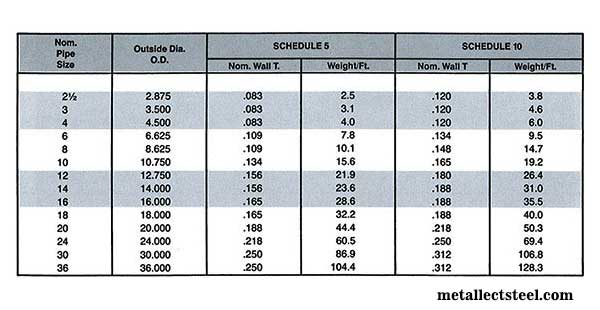

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type b Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, MSS-SP-43 Type A Fittings |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Fitting Machining Equipment: | Bending machine, Electric bevelling machine, Pushing Machine, Press machine, Sand-blasting machine etc |

IBR Approved Stub End

IBR Approved Threaded Plug

IBR Approved Socket Weld Union

IBR Approved Cross

IBR Approved Elbow

IBR Approved Tee

IBR Approved Reducer

IBR Approved End Cap

IBR Approved U Bend

IBR Approved Lateral Tee

| IBR Pipe Fittings Pressure Rating | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | |||||||

| (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | |||||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | |||

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | ||||

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | ||||

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | |||

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | ||||

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | ||||

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | |||

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | ||||

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | ||||

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | |||

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | ||||

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | ||||

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | |||

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | ||||

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | ||||

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | |||

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | ||||

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | ||||

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | |||

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | ||||

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | ||||

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | |||

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | ||||

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | ||||

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | |||

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | ||||

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | ||||

| Forms of Fttings | Fitting Size Range | Sch. of Buttweld fitting | Dimension Standards | |

|---|---|---|---|---|

| SMLS Pipe Fitting | Welded Fitting | |||

| IBR Approved Return Bends | 1/8” NB to 8" NB | SCH 5, SCH 5S, SCH 10, SCH 10S, SCH 20, SCH 30, SCH 40S, SCH 40, SCH STD, SCH 60, SCH 80s, SCH 100, SCH 120, SCH XS, SCH XXS, SCH 160, upto 50mm in case of Welded Fitting | ANSI B16.25, ASME B16.9, ASME B16.28, ANSI B16.28, ANSI B16.9, MS SP 75 | |

| IBR Approved End Caps | 1/8” NB to 24" NB | Upto 42" NB | ||

| IBR Approved Cross | 1/8” NB to 8" NB | |||

| IBR Approved Swage Nipple | 2 1/16” to 30” | |||

| IBR Approved Tees | 1/8” NB to 24" NB | Upto 42" NB | ||

| IBR Approved Reducers | 1/8” NB to 24" NB | Upto 42" NB | ||

| IBR Approved Elbows — 45, 90 & 180 Degree | 1/8” NB to 24" NB | Upto 42" NB | ||