-

-

send us mail

[email protected]

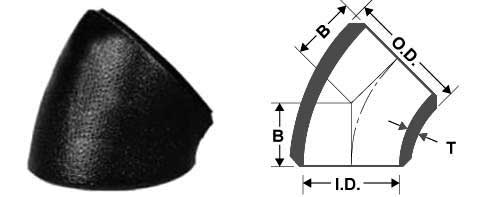

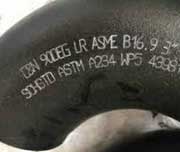

Carbon steel fittings used in either moderate or high temperature services are covered by the ASTM A234 Specification. The specified steel fittings covered include both seamless and welded kind of ASTM A234 WPB Elbow. Usually, both the carbon as well as alloy steel pipe fittings that are produced under this specification find use in pressure pipelines and in pressure vessel fabrications. The different kinds of fittings that could be produced under this specification includes Carbon Steel A234 WPB SCH 80 Elbow, tees, reducers, caps and crosses. Although these fittings normally adopt butt welding ends. A fitting used in any industry performs the function of changing either the rate of flow or the direction of the flow of media. In the instance of a Buttweld SA234 WPB Elbow, the change provided is with regards to the change in direction.

ASTM A234 WPB Elbow

Carbon Steel A234 WPB SCH 80 Elbow

Buttweld SA234 WPB Elbow

The material for these fittings consists of killed steel, bars, forgings, plates, seamless or HFW, which is also referred to as fusion welded pipe products, with an added filler metal.

| Pipe | Pipe Elbow Fitting | Flanges | Valves | Bolts & Nuts |

|---|---|---|---|---|

| A106 Gr A | A234 Gr WPA elbow | A105 | A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| A106 Gr B | ASTM A234 gr WPB elbow | A105 | A216 Gr WCB | |

| A106 Gr C | SA234 WPB Elbow | A105 | A216 Gr WCB |

Some of the more conventionally used elbows are angled at 22.5 degrees, 45 degrees and 90 degrees. For instance, the A234 WPB Buttweld Elbow 45 Degree is to change the flow of media, at an angle of 45 degrees. While all three i.e. 22.5 degrees, 45 degrees as well as the Elbow 90 A234 WPB are commonly used across several industries, most manufacturers today, cater to the buyer’s requirement by customizing the angle of the elbow fitting in addition to the alloy grade used and the surface treatment given to the respective fitting. The SA234 WPB SR And LR Elbow are widely used in industries like the oil and gas pipelines, power plants, chemical industries, nuclear power sites, in addition to being used in severe conditions.

| Standard Specification : | ASTM A234 WPB Elbow |

| Fitting Machining Equipment: | Press machine, electric bevelling machine, Bending machine, Pushing Machine, Sand-blasting machine etc |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Thickness: | View Our Thickness: Schedule 5S, Schedule10, Schedule20, Schedule10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | JIS B2313, ANSI B16.9, MSS-SP-43 Type A, MSS-SP-43 Type B, ANSI B16.28, JIS B2312, MSS-SP-43 Type b |

| Application: | Natural Gas Industry Oil And Gas Industry Chemical Industry Nuclear Power Plant Fabrication Industry Water Pipeline Industry |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Coating Fitting Faces : | Zinc Plated, Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized |

| NPS | Outside Dia. |

Inside Dia. |

Wall Thick. |

Center To End |

Pipe Schedule |

Weight Pounds |

| 1/2 | 0.84 | 0.622 | 0.109 | 0.62 | 40 | 0.09 |

| 3/4 | 1.05 | 0.824 | 0.113 | 0.75 | 40 | 0.1 |

| 1 | 1.32 | 1.05 | 0.133 | 0.88 | 40 | 0.22 |

| 1 1/4 | 1.66 | 1.38 | 0.14 | 1 | 40 | 0.33 |

| 1 1/2 | 1.9 | 1.61 | 0.145 | 1.12 | 40 | 0.43 |

| 2 | 2.38 | 2.07 | 0.154 | 1.38 | 40 | 0.85 |

| 2 1/2 | 2.88 | 2.47 | 0.203 | 1.75 | 40 | 1.7 |

| 3 | 3.5 | 3.07 | 0.216 | 2 | 40 | 2.5 |

| 3 1/2 | 4 | 3.55 | 0.226 | 2.25 | 40 | 3.4 |

| 4 | 4.5 | 4.03 | 0.237 | 2.5 | 40 | 4.5 |

| 5 | 5.56 | 5.05 | 0.258 | 3.12 | 40 | 7.5 |

| 6 | 6.62 | 6.06 | 0.28 | 3.75 | 40 | 11.7 |

| 8 | 8.62 | 7.98 | 0.322 | 5 | 40 | 23.3 |

| 10 | 10.75 | 10.02 | 0.365 | 6.25 | 40 | 40.9 |

| 12 | 12.75 | 12 | 0.375 | 7.5 | * | 61.4 |

| 14 | 14 | 13.25 | 0.375 | 8.75 | 30 | 78.1 |

| 16 | 16 | 15.25 | 0.375 | 10 | 30 | 101 |

| 18 | 18 | 17.25 | 0.375 | 11.25 | * | 128 |

| 20 | 20 | 19.25 | 0.375 | 12.5 | 20 | 159 |

| 24 | 24 | 23.25 | 0.375 | 15 | 20 | 231 |

| 30 | 30 | 29.25 | 0.375 | 18.5 | * | 358 |

| 36 | 36 | 35.25 | 0.375 | 22.25 | * | 518 |

| 42 | 42 | 41.25 | 0.375 | 26 | * | 707 |

| 48 | 48 | 47.25 | 0.375 | 29.88 | * | 1,000 |

A234 WPB Buttweld Elbow 45 Degree

Carbon Steel A234 90 Degree Pipe Elbow

CS A234 90 Deg Pipe Fittings Elbow

A234 Buttweld Elbow 180 Degree

SA234 WPB Elbow

Grade ASTM A234 WPB Elbow

Carbon Steel Grade sa234 wpb elbow

ANSI B16.9 SA234 elbow

ASTM A234 WPB gr Elbow 45 degree Short Radius

A234 Carbon Steel SMLS Elbow

Carbon Steel ASTM A234 gr WPB 3D Elbow

Black Steel A234 WPB Buttweld Elbow

| NPS | OD | Inside Dia. |

Wall Thick. |

Center To End |

Pipe Sch |

Weight Pound |

| 1/2 | 0.84 | 0.546 | 0.147 | 0.62 | 80 | 0.15 |

| 3/4 | 1.05 | 0.742 | 0.154 | 0.75 | 80 | 0.16 |

| 1 | 1.32 | 0.957 | 0.179 | 0.88 | 80 | 0.28 |

| 1 1/4 | 1.66 | 1.28 | 0.191 | 1 | 80 | 0.45 |

| 1 1/2 | 1.9 | 1.5 | 0.2 | 1.12 | 80 | 0.61 |

| 2 | 2.38 | 1.94 | 0.218 | 1.38 | 80 | 1.2 |

| 2 1/2 | 2.88 | 2.32 | 0.276 | 1.75 | 80 | 2 |

| 3 | 3.5 | 2.9 | 0.3 | 2 | 80 | 3.3 |

| 3 1/2 | 4 | 3.36 | 0.318 | 2.25 | 80 | 4.5 |

| 4 | 4.5 | 3.83 | 0.337 | 2.5 | 80 | 6.2 |

| 5 | 5.56 | 4.81 | 0.375 | 3.12 | 80 | 10.5 |

| 6 | 6.62 | 5.76 | 0.432 | 3.75 | 80 | 17 |

| 8 | 8.62 | 7.63 | 0.5 | 5 | 80 | 34.3 |

| 10 | 10.75 | 9.75 | 0.5 | 6.25 | 60 | 53.5 |

| 12 | 12.75 | 11.75 | 0.5 | 7.5 | * | 77.6 |

| 14 | 14 | 13 | 0.5 | 8.75 | * | 100 |

| 16 | 16 | 15 | 0.5 | 10 | 40 | 134 |

| 18 | 18 | 17 | 0.5 | 11.25 | * | 170 |

| 20 | 20 | 19 | 0.5 | 12.5 | 30 | 209 |

| 24 | 24 | 23 | 0.5 | 15 | * | 302 |

| 30 | 30 | 29 | 0.5 | 18.5 | 20 | 475.1 |

| 36 | 36 | 35 | 0.5 | 22.25 | 20 | 686.1 |

| 42 | 42 | 41 | 0.5 | 26 | * | 936.1 |

| 48 | 48 | 47 | 0.5 | 29.88 | * | 1250 |

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WPC | 0.35 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WP11 CL1 | 0.05-0.15 | 0.30-0.60 | 0.03 | 0.03 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

| WP11 CL2/3 | 0.05-0.20 | 0.30-0.80 | 0.04 | 0.04 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

| Tensile Requirements | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Tensile Strength, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% offset or 0.5% extension-under-load) | [415-585] | [485-655] | [415-585] | [520-690] |

| Yield Strength, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |