-

-

send us mail

[email protected]

Therefore the costs of manufacturing Aluminium Fittings tends to be lower. A reason why the metal is preferred for use in the engineering sector is that it not only reduces dead-weight but also reduces energy consumption while increasing capacity of the load. Furthermore, being lightweight, the Forged Aluminium Pipe Fittings offers another advantage with its reduction in noise, while improving comfort levels.

Aluminium is one of those metals that has the ability to naturally generate a thin oxide coating of a protective nature. This oxide coating present on the Aluminium Hydraulic Fitting is what keeps the metal from getting in contact with the environment. This property of aluminium is particularly useful for applications where the fitting are exposed to corrosive agents, in different industries. Different types of surface treatments could be applied to the Aluminium Buttweld Fittings such as anodising, painting or lacquering, all of which can further improve the corrosion resistance property of the material. Aluminium fitting are also non-toxic and non-magnetic.

Aluminium is a very light metal with its specific weight valued at 2.7 g/cm3, which is about a third of that of a regular steel alloy.

Aluminium Elbow Fitting is an excellent conductor of both heat and electricity. Moreover, in relation to its weight, aluminium fitting are almost two times as good a conductor as copper. Contrary to steel, which rapidly becomes brittle at low temperatures, Aluminium Door Fittings shows an increase in its tensile strength properties with a drop in its temperatures.

| Standard Specification : | Aluminium Fittings |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

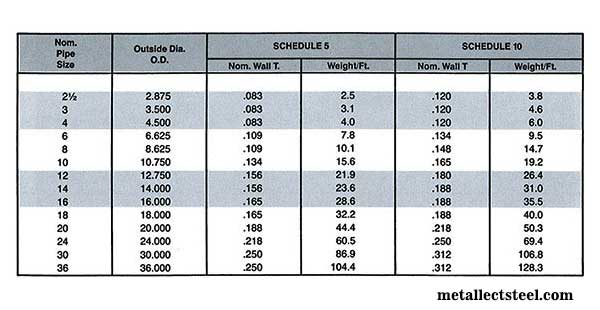

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Coating Fitting Faces : | Oil Black Paint, Zinc Plated, Cold and Hot Dip Galvanized, Yellow Transparent, Anti-rust Paint |

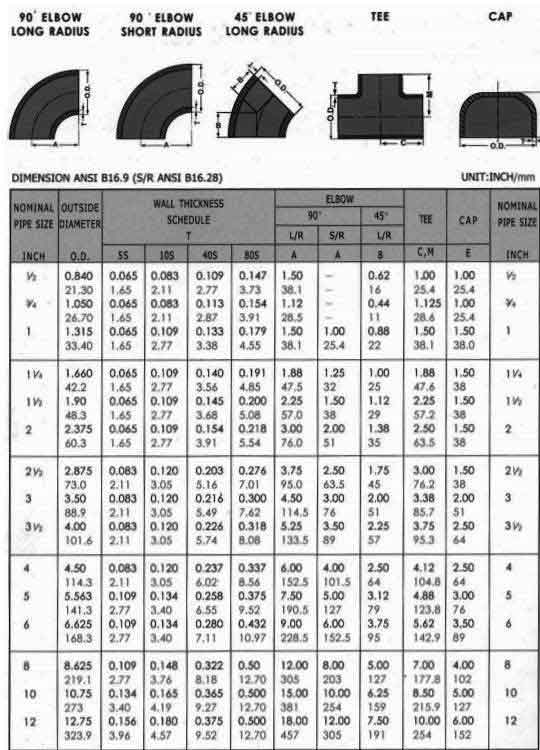

| Standard: | JIS B2313, ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, MSS-SP-43 Type b |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Application: | Chemical Industry Water Pipeline Industry Nuclear Power Plant Natural Gas Industry Fabrication Industry Oil And Gas Industry |

| Fitting Machining Equipment: | Electric bevelling machine, Press machine, Bending machine, Pushing Machine, Sand-blasting machine etc |

Aluminium Tee

Aluminium End Cap

Aluminium Elbow

Aluminium Reducer

Aluminium Threaded Plug

Aluminium Stub End

Aluminium Socket Weld Union

Aluminium Cross

Aluminium Lateral Tee

Aluminium U Bend

| Aluminium Fittings Pressure Rating | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| Aluminium 100 Fittings | Aluminium 200 Fittings | Aluminium 300 Fittings | Aluminium 400 Fittings | Aluminium 500 Fittings | Aluminium 600 Fittings | |||||||

| Allowable Stress (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | |||||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | |||

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | ||||

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | ||||

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | |||

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | ||||

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | ||||

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | |||

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | ||||

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | ||||

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | |||

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | ||||

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | ||||

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | |||

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | ||||

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | ||||

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | |||

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | ||||

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | ||||

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | |||

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | ||||

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | ||||

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | |||

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | ||||

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | ||||

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | |||

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | ||||

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | ||||