-

-

send us mail

[email protected]

Stainless steel is essentially a highly alloyed metal with a significant addition of chromium. The addition of chromium in the alloy used to make Stainless Steel Forged Fittings is what gives it superior resistance to oxidation. Chromium, if present in the alloy between 11% and higher reacts with oxygen available in the atmosphere to form a passivated, self-repairing oxide layer. Austenitic stainless steel grades like 316 and 304 are very often dual certified if the content of carbon has been reduced. Grade 304/ 304L Forged Stainless Steel Pipe Fittings could be used in an as welded condition due to its resistance to intergranular corrosion. Reduced content of carbon in the alloy of SS Forged Elbow is what improves the weldability properties of the fittings.

ASTM A182 Stainless Steel 304 Forged Fittings not only exhibits resistance to atmospheric corrosion, but also to moderately oxidizing and reducing environments.

Molybdenum bearing SS 316L Pipe Nipples are frequently used in process streams which could contain chlorides or halides, due to the alloys ability to resist chloride pitting while exhibiting impressive properties such as higher stress-to-rupture strength, higher creep, as well as tensile strength at elevated temperatures. Moreover, because the alloy has excellent resistance to brine, salt solution and seawater, the ASME B16.11 316L SS Socket weld Fittings or simply referred to as marine grade are used for marine engineering purposes. While grade 316 fittings tend to be more expensive as compared to grade 304, the properties of the former are much higher than the latter.

| Specification : | Stainless Steel Forged Fittings |

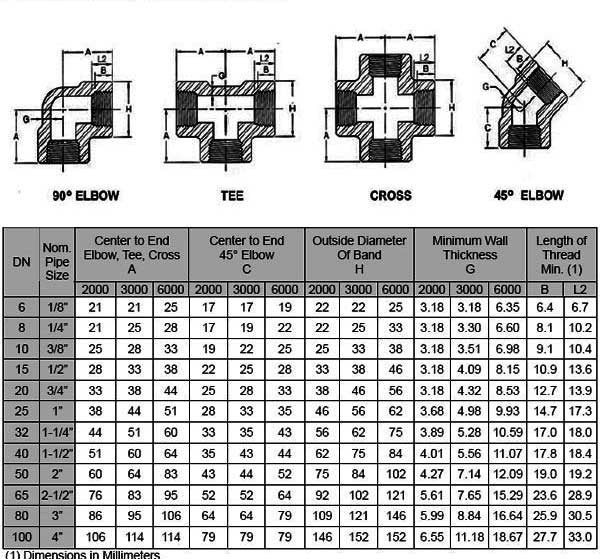

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Pressure: | Check Pressure Rating Of Socket, Threaded: 3000 LBS, 6000 LBS, 9000 LBS |

| Size Chart Of: | 1/8” NB to 4” NB (Screwed-Socket) |

| Forged Type : | NPT (Threaded), BSPT, BSPP. |

| Mills And Origin : | Europe, Russian, USA, India, Japanese |

| Stainless Steel Forged Fittings Standard Of: | ASME B16.47 Fittings, ASME B16.38 Fittings, MSS-SP-43 Fittings, JISB2313 Fittings, ASME B16.25 Fittings, MSS SP-75 Fittings, DIN2605 Fittings, JISB2312 Fittings, PN Fittings, AWWA C207 Fittings, BS4504 Fittings, BS1560 Fittings, BS, GB, ISO, JISB2311, IS 2062, DIN, ANSI B16.28, ASME B16.9, BS10 |

| Connection Type : | Welding |

Stainless Steel Forged Fittings

Stainless Steel 304 Forged Fittings

Forged Stainless Steel Pipe Fittings

SS forged fittings

Stainless Steel 317 Pipe Nipples

Stainless Steel 304 Forged Elbow

Stainless Steel 316 Threaded Pipe Fittings

ASTM A182 Stainless Steel Forged Fittings

Stainless Forged Elbow

Stainless Steel Forged Reducers

Stainless 304 Forged Fittings

ASTM A182 SS 347 Forged Fittings

| Type | C | Mn | P | S | Si | Cr | Ni | Mb |

|---|---|---|---|---|---|---|---|---|

| 302 | 0.15 | 2.00 | 0.045 | 0.030 | 1.00 | 17.00/19.00 | 8.00/10.00 | – |

| 304* | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.00/20.00 | 8.00/10.50 | – |

| 304L* | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 18.00/20.00 | 8.00/12.00 | – |

| 309 | 0.20 | 2.00 | 0.045 | 0.030 | 1.00 | 22.00/24.00 | 12.00/15.00 | – |

| 309S | 0.08 | 2.00 | 0.045 | – | 1.00 | 22.00/24.00 | – | – |

| 310 | 0.25 | 2.00 | 0.045 | 0.030 | 1.5 | 24.00/26.00 | 19.00/22.00 | – |

| 310S | 0.08 | 2.00 | 0.045 | 0.030 | 1.5 | 24.00/26.00 | 19.00/22.00 | – |

| 316* | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00/18.00 | 10.00/14.00 | 2.00/3.00 |

| 316L* | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00/18.00 | 10.00/14.00 | 2.00/3.00 |

| 317 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00/1.00 | 18.00/20.00 | 11.00/15.00 | 3.00/4.00 |

| 317L | 0.03 | 2.00 | 0.045 | 0.030 | 0.75 | 18.00/20.00 | 11.00/15.00 | 3.00/4.00 |

| 321 | 0.08 | 2.00 | 0.040 | 0.030 | 1.00 | 17.00/19.00 | 9.00/12.00 | 0.75/0.75 |

| 347 | 0.08 | 2.00 | 0.040 | 0.030 | 0.5/1.00 | 17.00/19.00 | 9.00/12.00 | 0.5/0.75 |

| Type | UNS | Tensile (ksi) minimum |

Yield (ksi) minimum |

Elongation minimum |

Hardness (Brinell) maximum |

Hardness (Rockwell B) maximum |

|---|---|---|---|---|---|---|

| 302 | S30200 | 75 | 30 | 40% in 2″ | 183 | 88 |

| 304* | S30400 | 75 | 30 | 40% in 2″ | 183 | 88 |

| 304L* | S30403 | 70 | 30 | 40% in 2″ | 183 | 88 |

| 309 | S30900 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 309S | S30908 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 310 | S31000 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 310S | S31008 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 316* | S31600 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 316L* | S31603 | 70 | 25 | 35% in 2″ | 217 | 95 |

| 317 | S31700 | 75 | 30 | 35% in 2″ | 217 | 95 |

| 317L | S31703 | 75 | 30 | 35% in 2″ | 217 | 95 |

| 321 | S32100 | 75 | 30 | 40% in 2″ | 183 | 88 |

| 347 | S34700 | 75 | 30 | 40% in 2″ | 183 | 88 |

| STANDARD | Stainless Steel Forged Fittings |

| UNS | S31603 |

| WERKSTOFF NO. | 1.4404 / 1.4435 |

| AFNOR | Z7CND17‐11‐02 |

| EN | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| JIS | SUS 316L |

| BS | 316S11 / 316S13 |

| GOST | 03Ch17N14M3 / 03Ch17N14M2 |

| Description | Stainless Steel Forged Fittings Class Designation | ||

|---|---|---|---|

| Class 3000 | Class 6000 | Class 9000 | |

| SW Elbows 45 degrees and NPT 90 Elbows degrees, SW Tees, NPT Crosses, SW Couplings, NPT Half-Couplings, Socket End or Pipe Caps |

1/2 – 4 | 1/2 – 2 | 1/2 – 2 |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| NPS by Wall Thick. |

SCH80 | SCH160 | XXS |