-

-

send us mail

[email protected]

Usually, carbon steel alloyed ASTM A234 WPB Tee is made by either pressing, hammering, upsetting, rolling, piercing, extruding, bending, fusion welding or by machining. On several occasions, these fittings could be processed by a combination of two or more of these operations. The WPB Carbon Steel Buttweld Equal Tee are available across the world in a seamless or a welded manner.

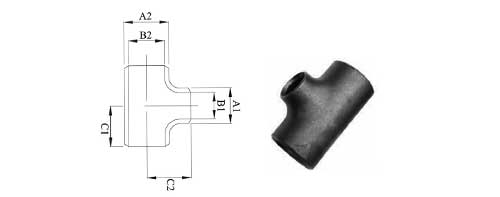

ASTM A234 WPB Tee

Carbon Steel Equal Tee A234 WPB

Buttweld A234 Reducing Tee

Designed to withstand moderate to elevated temperature settings fittings produced under the ASTM A234 specification could be forged by various shaping operations.

During the manufacturing process of these carbon steel pipe fittings, there are certain activities that are required to be noted:

Firstly, no injurious imperfections or welding defects are to be created on the Carbon Steel Equal Tee A234 WPB. Secondly, after the performance of any shaping or forming operations, the fittings at a suitable temperature, it shall be cooled in an appropriate environment. Which essentially, means that the Buttweld A234 Reducing Tee fitting is to be cooled to a temperature that below the critical range with no formation of defects on these fittings during the cooling procedures. However, it must be seen to it that manufacturers use a cooling process on the ASME B16.11 Lateral Tee A234 Wpb which must not be more rapid as compared to cooling in air.

Lastly, suitable inspection is to be mandatorily performed on the CS A234 Gr WPB Tee Pipe Fittings using appropriate test methods such as hydrostatic test, hardness test as well as tensile test after its manufacture.

| Nominal Pipe Size |

Dimensions of Run | Dimensions of Branch | Pipe Schedule |

Weight Pounds |

||||||

| Outside Diameter |

Wall Thickness T |

Inside Diameter |

Center to End C |

Outside Diameter |

Wall Thickness T |

Outside Diameter |

Center to End M |

|||

| 3/4 x 1/2 | 1.05 | 0.113 | 0.824 | 1.12 | 0.84 | 0.109 | 0.622 | 1.12 | 40 | 0.41 |

| 1 1/2 x 1 1/4 | 1.9 | 0.145 | 1.61 | 2.25 | 1.66 | 0.14 | 1.38 | 2.25 | 40 | 2 |

| 1 1/2 x 1 | 1.9 | 0.145 | 1.61 | 2.25 | 1.32 | 0.133 | 1.05 | 2.25 | 40 | 1.9 |

| 1 1/2 x 3/4 | 1.9 | 0.145 | 1.61 | 2.25 | 1.05 | 0.113 | 0.824 | 2.25 | 40 | 1.8 |

| 1 1/2 x 1/2 | 1.9 | 0.145 | 1.61 | 2.25 | 0.84 | 0.109 | 0.622 | 2.25 | 40 | 1.8 |

| 1 1/4 x 1 | 1.66 | 0.14 | 1.38 | 1.88 | 1.32 | 0.133 | 1.05 | 1.88 | 40 | 1.3 |

| 1 1/4 x 3/4 | 1.66 | 0.14 | 1.38 | 1.88 | 1.05 | 0.113 | 0.824 | 1.88 | 40 | 1.3 |

| 1 1/4 x 1/2 | 1.66 | 0.14 | 1.38 | 1.88 | 0.84 | 0.109 | 0.622 | 1.88 | 40 | 1.3 |

| 1 x 3/4 | 1.32 | 0.133 | 1.05 | 1.5 | 1.05 | 0.113 | 0.824 | 1.5 | 40 | 0.81 |

| 1 x 1/2 | 1.32 | 0.133 | 1.05 | 1.5 | 0.84 | 0.109 | 0.622 | 1.5 | 40 | 0.78 |

| 2 1/2 x 2 | 2.88 | 0.203 | 2.47 | 3 | 2.38 | 0.154 | 2.01 | 2.75 | 40 | 5.4 |

| 2 1/2 x 1 1/2 | 2.88 | 0.203 | 2.47 | 3 | 1.9 | 0.145 | 1.61 | 2.62 | 40 | 5.1 |

| 2 1/2 x 1 1/4 | 2.88 | 0.203 | 2.45 | 3 | 1.66 | 0.14 | 1.38 | 2.5 | 40 | 4.8 |

| 2 1/2 x 1 | 2.88 | 0.203 | 2.45 | 3 | 1.32 | 0.133 | 1.05 | 2.25 | 40 | 4.6 |

| 2 x 1 1/2 | 2.38 | 0.154 | 2.07 | 2.5 | 1.9 | 0.145 | 1.61 | 2.38 | 40 | 3.1 |

| 2 x 1 1/4 | 2.38 | 0.154 | 2.07 | 2.5 | 1.66 | 0.14 | 1.38 | 2.25 | 40 | 3 |

| 2 x 1 | 2.38 | 0.154 | 2.07 | 2.5 | 1.32 | 0.133 | 1.05 | 2 | 40 | 2.8 |

| 2 x 3/4 | 2.38 | 0.154 | 2.07 | 2.5 | 1.05 | 0.113 | 0.824 | 1.75 | 40 | 2.5 |

| 3 1/2 x 3 | 4 | 0.226 | 3.55 | 3.75 | 3.5 | 0.216 | 3.07 | 3.62 | 40 | 9.8 |

| 3 1/2 x 2 1/2 | 4 | 0.226 | 3.55 | 3.75 | 2.88 | 0.203 | 2.47 | 3.5 | 40 | 9.4 |

| 3 1/2 x 2 | 4 | 0.226 | 3.55 | 3.75 | 2.38 | 0.154 | 2.07 | 3.25 | 40 | 9.2 |

| 3 1/2 x 1 1/2 | 4 | 0.226 | 3.55 | 3.75 | 1.9 | 0.145 | 1.61 | 3.12 | 40 | 8.9 |

| 3 x 2 1/2 | 3.5 | 0.216 | 3.07 | 3.38 | 2.88 | 0.203 | 2.47 | 3.25 | 40 | 7.2 |

| 3 x 2 | 3.5 | 0.216 | 3.07 | 3.38 | 2.38 | 0.154 | 2.07 | 3 | 40 | 7 |

| 3 x 1 1/2 | 3.5 | 0.216 | 3.07 | 3.38 | 1.9 | 0.145 | 1.61 | 2.88 | 40 | 6.8 |

| 3 x 1 1/4 | 3.5 | 0.216 | 3.07 | 3.38 | 1.66 | 0.14 | 1.38 | 2.75 | 40 | 6.6 |

| 3 x 1 | 3.5 | 0.216 | 3.07 | 3.38 | 1.315 | 0.133 | 1.05 | 2 5/8 | 40 | 6.5 |

| 4 x 3 1/2 | 4.5 | 0.237 | 4.03 | 4.12 | 4 | 0.226 | 3.55 | 4 | 40 | 11.9 |

| 4 x 3 | 4.5 | 0.237 | 4.03 | 4.12 | 3.5 | 0.216 | 3.07 | 3.88 | 40 | 11.6 |

| 4 x 2 1/2 | 4.5 | 0.237 | 4.03 | 4.12 | 2.875 | 0.203 | 2.47 | 3.75 | 40 | 11.4 |

| 4 x 2 | 4.5 | 0.237 | 4.03 | 4.12 | 2.38 | 0.154 | 2.07 | 3.5 | 40 | 11.2 |

| 4 x 1 1/2 | 4.5 | 0.237 | 4.03 | 4.12 | 1.9 | 0.145 | 1.61 | 3.38 | 40 | 11.2 |

| 5 x 4 | 5.56 | 0.258 | 5.05 | 4.88 | 4.5 | 0.237 | 4.03 | 4.62 | 40 | 20.5 |

| 5 x 3 1/2 | 5.56 | 0.258 | 5.05 | 4.88 | 4 | 0.226 | 3.55 | 4.5 | 40 | 20 |

| 5 x 3 | 5.56 | 0.258 | 5.05 | 4.88 | 3.5 | 0.216 | 3.07 | 4.38 | 40 | 19.4 |

| 5 x 2 1/2 | 5.56 | 0.258 | 5.05 | 4.88 | 2.88 | 0.203 | 2.47 | 4.25 | 40 | 19 |

| 5 x 2 | 5.56 | 0.258 | 5.01 | 4.88 | 2.38 | 0.154 | 2.07 | 4.12 | 40 | 18.8 |

| 6 x 5 | 6.62 | 0.28 | 6.07 | 5.62 | 5.62 | 0.258 | 5.05 | 5.38 | 40 | 32 |

| 6 x 4 | 6.62 | 0.28 | 6.07 | 5.62 | 4.5 | 0.237 | 4.026 | 5.12 | 40 | 30.5 |

| 6 x 3 1/2 | 6.62 | 0.28 | 6.07 | 5.62 | 4 | 0.226 | 3.55 | 5 | 40 | 30 |

| 6 x 3 | 6.62 | 0.28 | 6.07 | 5.62 | 3.5 | 0.216 | 3.07 | 4.88 | 40 | 30 |

| 6 x 2 1/2 | 6.62 | 0.28 | 6.07 | 5.62 | 2.88 | 0.203 | 2.47 | 4.75 | 40 | 29.7 |

| 6 x 2 | 6.62 | 0.28 | 6.07 | 5.62 | 2.38 | 0.154 | 2.07 | 4.75 | 40 | 29 |

| 8 x 6 | 8.62 | 0.322 | 7.981 | 7 | 6.62 | 0.28 | 6.065 | 6.62 | 40 | 56.5 |

| 8 x 5 | 8.62 | 0.322 | 7.981 | 7 | 5.56 | 0.258 | 5.047 | 6.38 | 40 | 54 |

| 8 x 4 | 8.62 | 0.322 | 7.981 | 7 | 4.5 | 0.237 | 4.026 | 6.12 | 40 | 53.2 |

| 8 x 3 1/2 | 8.62 | 0.322 | 7.981 | 7 | 4 | 0.226 | 3.548 | 6 | 40 | 53 |

| 8 x 3 | 8.62 | 0.322 | 7.981 | 7 | 3.5 | 0.216 | 3.068 | 6 | 40 | 52 |

| 10 x 8 | 10.75 | 0.365 | 10.02 | 8.5 | 8.62 | 0.322 | 7.981 | 8 | 40 | 86.5 |

| 10 x 6 | 10.75 | 0.365 | 10.02 | 8.5 | 6.62 | 0.28 | 6.065 | 7.62 | 40 | 85.9 |

| 10 x 5 | 10.75 | 0.365 | 10.02 | 8.5 | 5.56 | 0.258 | 5.047 | 7.5 | 40 | 82.5 |

| 10 x 4 | 10.75 | 0.365 | 10.02 | 8.5 | 4.5 | 0.237 | 4.026 | 7.25 | 40 | 82 |

| 10 x 3 | 10.75 | 0.365 | 10.02 | 8.5 | 3.5 | 0.216 | 3.068 | 7.25 | 40 | 79 |

| 12 x 10 | 12.75 | 0.375 | 12 | 10 | 10.75 | 0.365 | 10.02 | 9.5 | * | 123 |

| 12 x 8 | 12.75 | 0.375 | 12 | 10 | 8.62 | 0.322 | 7.981 | 9 | * | 120 |

| 12 x 6 | 12.75 | 0.375 | 12 | 10 | 6.62 | 0.28 | 6.065 | 8.62 | * | 118 |

| 12 x 5 | 12.75 | 0.375 | 12 | 10 | 5.56 | 0.258 | 5.047 | 8.5 | * | 117 |

| 12 x 4 | 12.75 | 0.375 | 12 | 10 | 4.5 | 0.237 | 4.026 | 8.5 | * | 112 |

| 14 x 12 | 14 | 0.375 | 13.25 | 11 | 12.75 | 0.375 | 12 | 10.62 | 30 | 151 |

| 14 x 10 | 14 | 0.375 | 13.25 | 11 | 10.75 | 0.365 | 10.02 | 10.12 | 30 | 148 |

| 14 x 8 | 14 | 0.375 | 13.25 | 11 | 8.62 | 0.322 | 7.981 | 9.75 | 30 | 146 |

| 14 x 6 | 14 | 0.375 | 13.25 | 11 | 6.62 | 0.28 | 6.065 | 9.38 | 30 | 145 |

| 16 x 14 | 16 | 0.375 | 15.25 | 12 | 14 | 0.375 | 13.25 | 12 | 30 | 221 |

| 16 x 12 | 16 | 0.375 | 15.25 | 12 | 12.75 | 0.375 | 12 | 11.62 | 30 | 213 |

| 16 x 10 | 16 | 0.375 | 15.25 | 12 | 10.75 | 0.365 | 10.02 | 11.12 | 30 | 197 |

| 16 x 8 | 16 | 0.375 | 15.25 | 12 | 8.62 | 0.322 | 7.981 | 10.75 | 30 | 190 |

| 16 x 6 | 16 | 0.375 | 15.25 | 12 | 6.62 | 0.28 | 6.065 | 10.38 | 30 | 180 |

| 18 x 16 | 18 | 0.375 | 17.25 | 13.5 | 16 | 0.375 | 15.25 | 13 | * | 262 |

| 18 x 14 | 18 | 0.375 | 17.25 | 13.5 | 14 | 0.375 | 13.25 | 13 | * | 248 |

| 18 x 12 | 18 | 0.375 | 17.25 | 13.5 | 12.75 | 0.375 | 12 | 12.62 | * | 241 |

| 18 x 10 | 18 | 0.375 | 17.25 | 13.5 | 10.75 | 0.365 | 10.02 | 12.12 | * | 229 |

| 18 x 8 | 18 | 0.375 | 17.25 | 13.5 | 8.62 | 0.322 | 7.981 | 11.75 | * | 216 |

| 20 x 18 | 20 | 0.375 | 19.25 | 15 | 18 | 0.375 | 17.25 | 14.5 | 20 | 352 |

| 20 x 16 | 20 | 0.375 | 19.25 | 15 | 16 | 0.375 | 15.25 | 14 | 20 | 339 |

| 20 x 14 | 20 | 0.375 | 19.25 | 15 | 14 | 0.375 | 13.25 | 14 | 20 | 327 |

| 20 x 12 | 20 | 0.375 | 19.25 | 15 | 12.75 | 0.375 | 12 | 13.62 | 20 | 315 |

| 20x 10 | 20 | 0.375 | 19.25 | 15 | 10.75 | 0.365 | 10.02 | 13.12 | 20 | 305 |

| 20 x 8 | 20 | 0.375 | 19.25 | 15 | 8.62 | 0.322 | 7.981 | 12.75 | 20 | 293 |

| 24 x 20 | 24 | 0.375 | 23.25 | 17 | 20 | 0.375 | 19.25 | 17 | 20 | 500 |

| 24 x 18 | 24 | 0.375 | 23.25 | 17 | 18 | 0.375 | 17.25 | 16.5 | 20 | 487 |

| 24 x 16 | 24 | 0.375 | 23.25 | 17 | 16 | 0.375 | 15.25 | 16 | 20 | 475 |

| 24 x 14 | 24 | 0.375 | 23.25 | 17 | 14 | 0.375 | 13.25 | 16 | 20 | 465 |

| 24 x 12 | 24 | 0.375 | 23.25 | 17 | 12.75 | 0.375 | 12 | 15.62 | 20 | 450 |

| 24 x 10 | 24 | 0.375 | 23.25 | 17 | 10.75 | 0.365 | 10.02 | 15.12 | 20 | 447 |

| 30 x 24 | 30 | 0.38 | 29.24 | 22 | 24 | 0.38 | 23.24 | 21 | * | 795 |

| 30 x 20 | 30 | 0.38 | 29.24 | 22 | 20 | 0.38 | 19.24 | 20 | * | 749 |

| 30 x 18 | 30 | 0.38 | 29.24 | 22 | 18 | 0.38 | 17.24 | 19.5 | * | 727 |

| 36 x 30 | 36 | 0.38 | 35.24 | 26.5 | 30 | 0.38 | 29.24 | 25 | * | 1,207 |

| 36 x 24 | 36 | 0.38 | 35.24 | 26.5 | 24 | 0.38 | 23.24 | 24 | * | 1,129 |

| 36 x 20 | 36 | 0.38 | 35.24 | 26.5 | 20 | 0.38 | 19.24 | 23 | * | 1,072 |

| 36 x18 | 36 | 0.38 | 35.24 | 26.5 | 18 | 0.38 | 17.24 | 22.5 | * | 1,136 |

| 42 x 40 | 42 | 0.38 | 41.24 | 30 | 40 | 0.38 | 39.24 | 28 | * | 1,468 |

| 42 x 36 | 42 | 0.38 | 41.24 | 30 | 36 | 0.38 | 35.24 | 28 | * | 1,415 |

| 42 x 30 | 42 | 0.38 | 41.24 | 30 | 30 | 0.38 | 29.24 | 28 | * | 1,327 |

| 42 x 24 | 42 | 0.38 | 41.24 | 30 | 24 | 0.38 | 23.24 | 26 | * | 1,248 |

| 48 x 42 | 48 | 0.38 | 47.24 | 35 | 42 | 0.38 | 41.24 | 32 | * | 2,207 |

| 48 x 38 | 48 | 0.38 | 47.24 | 35 | 38 | 0.38 | 37.24 | 32 | * | 2,154 |

| 48 x 36 | 48 | 0.38 | 47.24 | 35 | 36 | 0.38 | 35.24 | 31 | * | 2,127 |

| 48 x 30 | 48 | 0.38 | 47.24 | 35 | 30 | 0.38 | 29.24 | 30 | * | 2,048 |

| Standard Specification : | ASTM A234 WPB Tee |

| Standard: | MSS-SP-43 Type A, MSS-SP-43 Type B, ANSI B16.28, JIS B2313, ANSI B16.9, JIS B2312, MSS-SP-43 Type b |

| Application: | Natural Gas Industry Oil And Gas Industry Chemical Industry Nuclear Power Plant Fabrication Industry Water Pipeline Industry |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Coating Fitting Faces : | Zinc Plated, Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized |

| Fitting Machining Equipment: | Electric bevelling machine, Press machine, Bending machine, Pushing Machine, Sand-blasting machine etc |

| Thickness: | View Our Thickness: SCH 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| NPS | OD | Inside Dia. |

Wall Thick. |

Center To End |

Pipe Sch |

Weight Pound |

| 1/2 | 0.84 | 0.546 | 0.147 | 0.62 | 80 | 0.15 |

| 3/4 | 1.05 | 0.742 | 0.154 | 0.75 | 80 | 0.16 |

| 1 | 1.32 | 0.957 | 0.179 | 0.88 | 80 | 0.28 |

| 1 1/4 | 1.66 | 1.28 | 0.191 | 1 | 80 | 0.45 |

| 1 1/2 | 1.9 | 1.5 | 0.2 | 1.12 | 80 | 0.61 |

| 2 | 2.38 | 1.94 | 0.218 | 1.38 | 80 | 1.2 |

| 2 1/2 | 2.88 | 2.32 | 0.276 | 1.75 | 80 | 2 |

| 3 | 3.5 | 2.9 | 0.3 | 2 | 80 | 3.3 |

| 3 1/2 | 4 | 3.36 | 0.318 | 2.25 | 80 | 4.5 |

| 4 | 4.5 | 3.83 | 0.337 | 2.5 | 80 | 6.2 |

| 5 | 5.56 | 4.81 | 0.375 | 3.12 | 80 | 10.5 |

| 6 | 6.62 | 5.76 | 0.432 | 3.75 | 80 | 17 |

| 8 | 8.62 | 7.63 | 0.5 | 5 | 80 | 34.3 |

| 10 | 10.75 | 9.75 | 0.5 | 6.25 | 60 | 53.5 |

| 12 | 12.75 | 11.75 | 0.5 | 7.5 | * | 77.6 |

| 14 | 14 | 13 | 0.5 | 8.75 | * | 100 |

| 16 | 16 | 15 | 0.5 | 10 | 40 | 134 |

| 18 | 18 | 17 | 0.5 | 11.25 | * | 170 |

| 20 | 20 | 19 | 0.5 | 12.5 | 30 | 209 |

| 24 | 24 | 23 | 0.5 | 15 | * | 302 |

| 30 | 30 | 29 | 0.5 | 18.5 | 20 | 475.1 |

| 36 | 36 | 35 | 0.5 | 22.25 | 20 | 686.1 |

| 42 | 42 | 41 | 0.5 | 26 | * | 936.1 |

| 48 | 48 | 47 | 0.5 | 29.88 | * | 1250 |

ASTM A234 gr WPB tee

Tee Std Wt Stl A234 Wpb

Lateral Tee A234 Wpb

Bw ASTM A234 WPB Tee

ASTM A234 Reducing Tee

CS ASTM A234 gr WPB Equal Tee

ANSI B16.9 CS A234 WPB Equal Tee

WPB Carbon Steel Buttweld Equal Tee

ASTM A234 WPB Carbon Steel Buttweld Tee

A234 Grade WPB Buttweld Unequal Tee

A234 Gr WPB Tee Pipe Fittings

ASME SA A234 Grade WPB Tee

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WPC | 0.35 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WP11 CL1 | 0.05-0.15 | 0.30-0.60 | 0.03 | 0.03 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

| WP11 CL2/3 | 0.05-0.20 | 0.30-0.80 | 0.04 | 0.04 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

| Tensile Requirements | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Tensile Strength, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% offset or 0.5% extension-under-load) | [415-585] | [485-655] | [415-585] | [520-690] |

| Yield Strength, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

| Pipe | Pipe Tee Fitting | Flanges | Valves | Bolts & Nuts |

|---|---|---|---|---|

| A106 Gr A | A234 Gr WPA tee | A105 | A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| A106 Gr B | ASTM A234 gr WPB tee | A105 | A216 Gr WCB | |

| A106 Gr C | A234 Gr WPC tee | A105 | A216 Gr WCB |