-

-

send us mail

[email protected]

WPHY, or as also known as Wrought high Yield strength fittings as its the name suggests have a high yield strength. Therefore, the ASTM A860 WPHY 70 Fittings are primarily used in industries such as Power Plants, Chemical Plants, Oil Refineries, Shipbuilders as well as Offshore Platforms, and Petrochemical industries. Low alloyed CS ASTM A860 WPHY 70 Buttweld Fittings produced under this specification are either constructed in a seamless or in an electric fusion welded manner. Although the cost and construction methods of both seamless &welded fittings vary, with a proper finishing performed on the ASTM A860 Gr WPHY 70 High Yield U Bend, the appearance of a welded seam could be minimized extensively, such that it is barely visible to naked eyes. Usually, a seamlessly constructed SA860 WPHY 70 Lateral Tee is preferred on account of its smooth finish.

ASTM A860 WPHY 70 Fittings

Buttweld A860 Gr WPHY 70 Elbow

Carbon Steel WPHY 70 Material

Fittings with the term WPHY attached to it are the preferred choice for applications involving High Pressure environments.

Apart from the chemical and mechanical property requirements for these fittings, the Carbon Steel WPHY 70 Material is to be heat treated by conducting operations like normalizing, quenching, and tempering or stress relieving. Moreover, the Buttweld A860 Gr WPHY 70 Elbow is required to conform to values such as elongation, yield strength, tensile strength, notch toughness, and hardness.

| Standard Specification : | ASTM A860 WPHY 70 Fittings |

| Fitting Machining Equipment: | Sand-blasting machine, Press machine, Bending machine, Electric bevelling machine, Pushing Machine etc |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

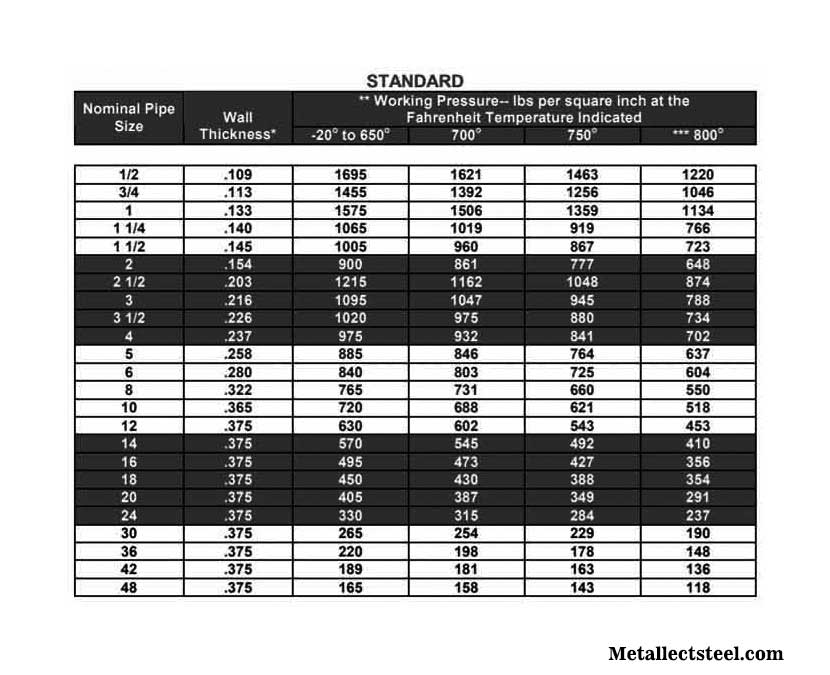

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Standard: | MSS-SP-43 Type b Fittings, MSS-SP-43 Type A Fittings, ANSI B16.28 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, JIS B2312 Fittings, MSS-SP-43 Type B Fittings |

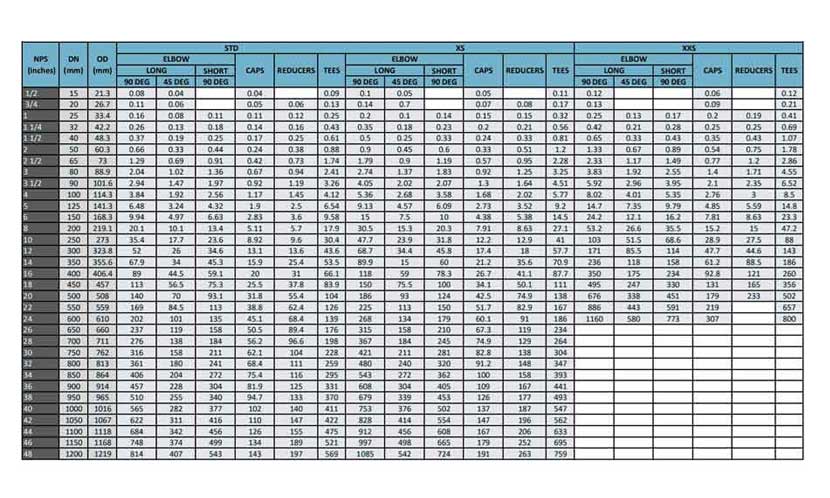

| Thickness: | View Our Thickness: Sch5S, Sch10, Sch20, Sch10, Sch20, Sch30, SchTD, Sch40, Sch60, XS, Sch80, Sch100, Sch120, Sch140, Sch160. |

| Application: | Nuclear Power Plant Natural Gas Industry Oil And Gas Industry Fabrication Industry Water Pipeline Industry Chemical Industry |

| Coating Fitting Faces : | Anti-rust Paint, Zinc Plated, Oil Black Paint, Cold and Hot Dip Galvanized, Yellow Transparent |

Carbon Steel A860 70 Weld Lateral Tee

High Yield Carbon Steel A860 70 End Cap

ASTM A860 Carbon Steel WPHY 70 Reducing Tee

ASTM A860 High Yield Gr WPHY 70 Stub Ends

A860 Carbon Steel-70 Equal Tee

A860 Gr 70 180 Deg Elbow

WPHY 70 BW Cross Fitting

MSS SP 75 WPHY 70 Material

Buttweld WPHY-70 Concentric Reducer

MSS SP 75 70 Eccentric Reducer

ASTM A860 Gr WPHY 70 45 Degree Elbow

Carbon Steel MSS SP75 70 90 Deg Elbow

| C | Mn | P | S | Si | Ni | Cr | Mo | Cu | Ti | V | Cb | Al | |

| A860 WPHY 70 | 0.20 | 1.00-1.45 | 0.03 | 0.01 | 0.15-0.40 | 0.50 | 0.30 | 0.25 | 0.35 | 0.05 | 0.10 | 0.04 | 0.06 |

| Tensile Strength (mpa) | Yield Strength (mpa) | |

| A860 WPHY 70 | 485 | 570 |

ASTM A860 API 5L X70 elbow manufacturer

3.ASTM A860 MSS SP 75 70 Reducer

WT: sch40/ std/ sch80/ thick-wall

Carbon Steel Grade WPHY 70 Pipe Concentric

A860 WPHY 70 Eccentric Reducer

MSS SP 75 A860 WPHY 70 Con/ Ecc Reducer

4. Buttweld-WPHY 70 SMLS CAP

MSS SP 75 WPHY 70 cap

Cap Pipe fittings

5. A860 Carbon Steel-WPHY 70 Stubend

ASTM A860 60 Stubend

these Material ASTM A860 Buttweld are known for accurate dimension, corrosion resistance and durability.

A860 Gr WPHY 70 Short Stubend

ASTM A860 WPHY 70 BW Long Stubend