-

-

send us mail

[email protected]

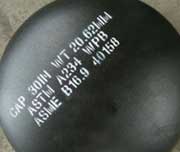

The ASME B16.9 is a standard that covers several parameters such as the overall dimensions, tolerances, testing, ratings, as well as markings for wrought butt-welding fittings produced in the factory, with their size ranging between NPS 1/2 through NPS 48. On the other hand, the specified ASTM A234 WPB Cap is a fitting that is covered by ASTM A234 that could be constructed either in a seamless or a welded manner. The materials used to produce these fittings include wrought type carbon or alloy steel grades. The ASTM A234 is a specification that lists down several forming or shaping operations that the CS Pipe Cap A234 WPB could undergo. These operations include hammering, pressing, piercing, bending, fusion welding, extruding, upsetting, rolling and machining. This being said, the specification also mentions that these Carbon Steel SA234 Pipe Caps could be forged by either two or more of the aforementioned operations in order to achieve the desired results.

ASTM A234 WPB Cap

SA234 WPB Pipe Caps

Buttweld A234 WPB End Cap

Both the ASME B16.9 Pipe Cap A234 WPB are specifications that cater to fittings that are designed to be used in environments between a moderate to high temperature range.

Although the function of a Buttweld A234 WPB End Cap is to protect the ends of a pipe or a fitting, the important task performed by the end cap is to waterproof the connections. Moreover, a Gr ASTM A234 WPB Cap could also be used to close or seal off the ends of either a hydraulic or a pneumatic pipe in a system.

| Normal Pipe Sizes (NPS) | O.D. (Outside Daimeter) | I.D. (Inside Daimeter) | Wall Thickness |

Length | Pipe schedule |

Weight In Pound |

| 1/2 | 0.84 | 0.622 | 0.109 | 1 | 40 | 0.08 |

| 3/4 | 1.05 | 0.824 | 0.113 | 1.25 | 40 | 0.14 |

| 1 | 1.32 | 1.049 | 0.133 | 1.5 | 40 | 0.21 |

| 1 1/4 | 1.66 | 1.38 | 0.14 | 1.5 | 40 | 0.33 |

| 1 1/2 | 1.9 | 1.61 | 0.145 | 1.5 | 40 | 0.54 |

| 2 | 2.38 | 2.067 | 0.154 | 1.5 | 40 | 0.8 |

| 2 1/2 | 2.88 | 2.469 | 0.203 | 1.5 | 40 | 1 |

| 3 | 3.5 | 3.068 | 0.216 | 2 | 40 | 1.7 |

| 3 1/2 | 4 | 3.548 | 0.226 | 2.5 | 40 | 2.3 |

| 4 | 4.5 | 4.026 | 0.237 | 2.5 | 40 | 2.8 |

| 5 | 5.56 | 5.047 | 0.258 | 3 | 40 | 4.6 |

| 6 | 6.62 | 6.065 | 0.28 | 3.5 | 40 | 6.9 |

| 8 | 8.62 | 7.981 | 0.322 | 4 | 40 | 11.8 |

| 10 | 10.75 | 10.02 | 0.365 | 5 | 40 | 20.8 |

| 12 | 12.75 | 12 | 0.375 | 6 | * | 30.3 |

| 14 | 14 | 13.25 | 0.375 | 6.5 | 30 | 36.5 |

| 16 | 16 | 15.25 | 0.375 | 7 | 30 | 43.5 |

| 18 | 18 | 17.25 | 0.375 | 8 | * | 57 |

| 20 | 20 | 19.25 | 0.375 | 9 | 20 | 75.7 |

| 24 | 24 | 23.25 | 0.375 | 10.5 | 20 | 101 |

| 30 | 30 | 29.24 | 0.38 | 10.5 | * | 137 |

| 36 | 36 | 35.24 | 0.38 | 10.5 | * | 175 |

| 42 | 42 | 41.24 | 0.38 | 12 | * | 229 |

| 48 | 48 | 47.24 | 0.38 | 13.5 | * | 350 |

| Standard Specification : | ASTM A234 WPB Cap |

| Standard: | JIS B2312, ANSI B16.28, JIS B2313, ANSI B16.9, MSS-SP-43 Type b, MSS-SP-43 Type A, MSS-SP-43 Type B |

| Coating Fitting Faces : | Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated, Yellow Transparent |

| Fitting Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine,Electric bevelling machine, Press machine etc |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Thickness: | View Our Thickness: SCH 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Application: | Nuclear Power Plant Oil And Gas Industry Chemical Industry Fabrication Industry Natural Gas Industry Water Pipeline Industry |

SA234 WPB Pipe Caps

Pipe Cap A234 WPB

Cap STD WT STL A234

Carbon Steel ASTM A234 Pipe Cap

Carbon Steel A234 WPB End Cap

ANSI B16.9 Pipe Cap A234

ASTM A234 WPB Cap

ASME SA234 WPB Carbon Steel Buttweld End Cap

ASME B16.9 Carbon WPB End Cap

Carbon Steel WPB Pipe End Cap

Grade Carbon Steel ASTM A234 End Cap

BW A234 Pipe Cap

| Normal Size Of Pipe (NPS) | STD | XS | SCH 160 | XXS |

| 1 | 0.09 | 0.14 | 0.18 | 0.23 |

| 1.1/4 | 0.14 | 0.18 | 0.23 | 0.34 |

| 1.1/2 | 0.18 | 0.23 | 0.27 | 0.41 |

| 2 | 0.27 | 0.34 | 0.57 | 0.68 |

| 2.1/2 | 0.41 | 0.45 | 0.79 | 1.13 |

| 3 | 0.68 | 0.79 | 1.32 | 1.81 |

| 3.1/2 | 0.91 | 1.13 | – | 2.72 |

| 4 | 1.13 | 1.36 | 2.68 | 3.4 |

| 5 | 2.04 | 2.49 | 4.54 | 5.44 |

| 6 | 2.95 | 4.08 | 6.8 | 8.16 |

| 8 | 5.44 | 7.26 | 14.06 | 13.61 |

| 10 | 9.07 | 11.34 | 25.85 | – |

| 12 | 13.61 | 16.33 | 43.09 | – |

| 14 | 16.33 | 20.41 | – | – |

| 16 | 18.14 | 24.49 | – | – |

| 18 | 24.49 | 32.66 | – | – |

| 20 | 34.02 | 39.01 | – | – |

| 22 | 42.64 | 56.7 | – | – |

| 24 | 43.54 | 58.97 | – | – |

| 26 | 53.98 | 72.12 | – | – |

| 30 | 78.02 | 103.87 | – | – |

| Size And schedule | Price In INR (Per Piece) |

| 1/2 Inch X Schedule 16 | 175.25 |

| 3/4 Inch X Schedule 160 | 250.00 |

| 1 Inch X Schedule 160 | 300.00 |

| 1 1/4 Inch X Schedule 40 | 350.00 |

| 1 1/2 Inch X Schedule 80 | 390.97 |

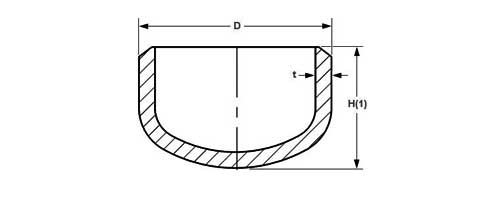

| Normal Size Of Pipes (NPS) | (O.D.) D |

Length H |

Length H1 |

| 1/2 | 21.3 | 25 | 25 |

| 3/4 | 26.7 | 25 | 25 |

| 1 | 33.4 | 38 | 38 |

| 1¼ | 42.2 | 38 | 38 |

| 1½ | 48.3 | 38 | 38 |

| 2 | 60.3 | 38 | 44 |

| 2½ | 73 | 38 | 51 |

| 3 | 88.9 | 51 | 64 |

| 3½ | 101.6 | 64 | 76 |

| 4 | 114.3 | 64 | 76 |

| 5 | 141.3 | 76 | 89 |

| 6 | 168.3 | 89 | 102 |

| 8 | 219.1 | 102 | 127 |

| 10 | 273 | 127 | 152 |

| 12 | 323.8 | 152 | 178 |

| 14 | 355.6 | 165 | 191 |

| 16 | 406.4 | 178 | 203 |

| ASME B16.9 End Cap Tolerances | ||||

| All fittings | Pipe Caps | |||

| (Normal Size Of Pipe) NPS | Outside Daimeter Ø at Bevel | Inside Daimeter Ø at End | Wall Thickness t / t1 |

Overall Length E |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 4 |

| 3 a 3 1/2 | 1 | 1,6 | less | 4 |

| 4 | +2 -1 | 1,6 | than | 4 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 7 |

| 8 | 2 | 1,6 | of nominal | 7 |

| 10 | +4 -3 | 3,2 | tickness | 7 |

| 12 a 18 | +4 -3 | 3,2 | 7 | |

| 20 a 24 | +6 -5 | 4,8 | 7 | |

| 26 a 30 | +7 -5 | 4,8 | 10 | |

| 32 a 48 | +7 -5 | 4,8 | 10 | |

| ASTM A234 WPB Cap Pressure Ratings (psig) | |||||

|---|---|---|---|---|---|

| Temperature Ratings | Pressure Class | ||||

| Class 150 | Class 300 | ||||

| 1/4 - 1 Inches | 1 1/4 - 2 Inches | 2 1/2 - 3 Inches | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |