-

-

send us mail

[email protected]

While specification ASTM A860 WPHY 60 Fittings conform to several mechanical properties such as yield strength, tensile strength, in addition to elongation, notch toughness, and hardness. Specification MSS SP75 is indicative of the fittings yield strength in 1000’s PSI, which is also referred to as its grade. Therefore the minimum yield strength of the MSS SP75 WPHY 60 Cap Material is approx 60000 PSI. As the value of the fittings minimum yield strength increases, most manufacturers keep a stricter control on the content of carbon in its alloy. The CS Gr MSS SP75 WPHY 60 Buttweld Tee is designed to be used in the oil and gas industry, where these fittings are exposed to high pressured transmission and distribution systems.

ASTM A860 WPHY 60 Fittings

MSS SP75 WPHY 60 Cap Material

Carbon Steel A860 WPHY 60 Elbow

Wrought plate or pipe high yield fittings or as shortened as WPHY fittings are generally manufactured under specifications ASTM A860 and MSS SP75.

| Grade | C | Mn | S | P | Si | Ni | Cr | Mo | Cu | Ti | V | Cb | Al |

| ASTM A860 WPHY 60 Fittings | 0.20 | 1.00-1.45 | 0.03 | 0.01 | 0.15-0.40 | 0.50 | 0.30 | 0.25 | 0.35 | 0.05 | 0.10 | 0.06 |

| Standard Specification : | ASTM A860 WPHY 60 Fittings |

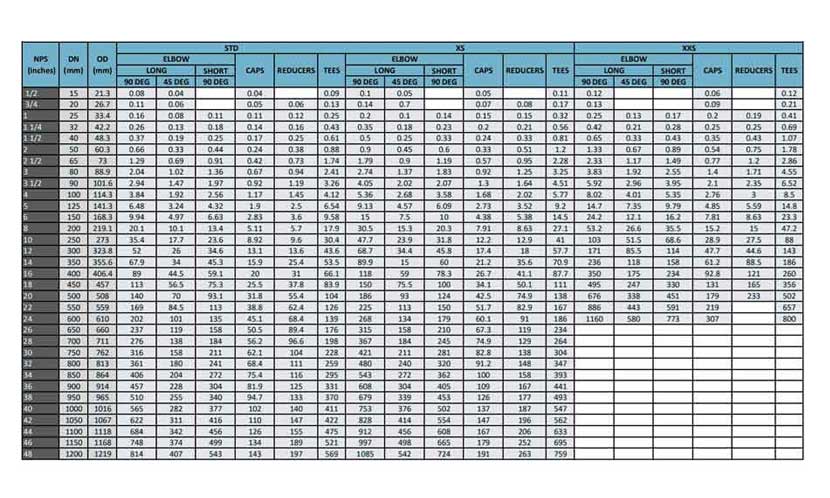

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Standard: | MSS-SP-43 Type A Fittings, JIS B2312 Fittings, ANSI B16.28 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type b Fittings, MSS-SP-43 Type B Fittings |

| Application: | Chemical Industry Natural Gas Industry Oil And Gas Industry Fabrication Industry Nuclear Power Plant Water Pipeline Industry |

| Fitting Machining Equipment: | Press machine, Bending machine, Electric bevelling machine, Sand-blasting machine, Pushing Machine etc |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

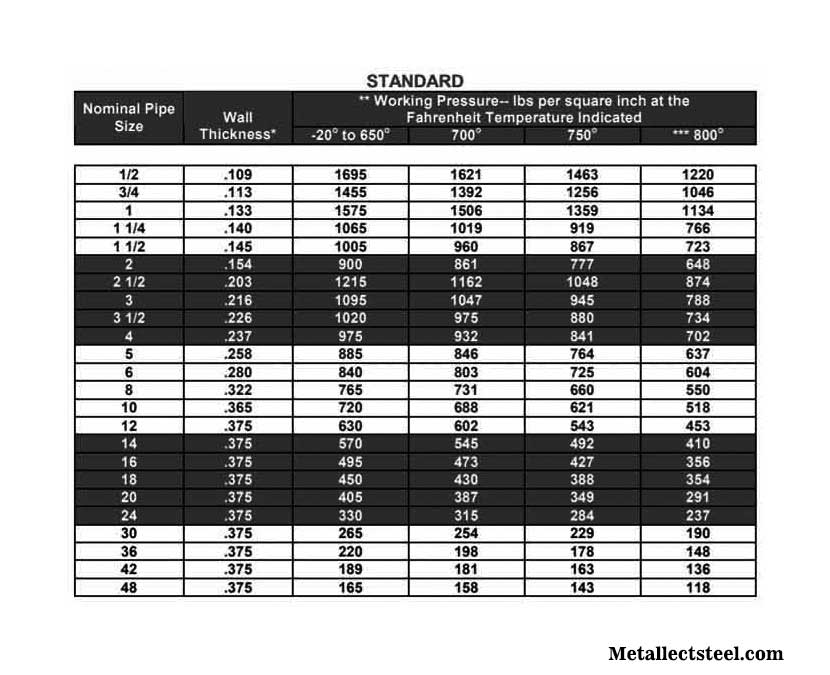

| Thickness: | View Our Thickness: Sch5S, Sch10, Sch20, Sch10, Sch20, Sch30, SchTD, Sch40, Sch60, XS, Sch80, Sch100, Sch120, Sch140, Sch160. |

| Coating Fitting Faces : | Zinc Plated, Oil Black Paint, Yellow Transparent, Cold and Hot Dip Galvanized, Anti-rust Paint |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

The SA860 Grade 60 Pipe Nipple is a length of straight pipe, which is constructed with male threads on both ends. These pipe nipples are considered to be one of the most popular categories of pipe fittings. These fittings are essentially a connector or they could have coupling threaded on both ends. Buttweld A860 WPHY 60 Seamless Fittings like Pipe nipples could be used to permit plumbing to be connected to a water heater or to other plumbing systems. An elbow is also used to connect piping systems while changing the flow of media at a certain angle. Generally, the Carbon Steel A860 WPHY 60 Elbow is produced in three angles i.e. 90 degrees, 45 degrees and 22.5 degrees. However, if customizations are required, many manufacturers are able to tailor make them keeping the application in mind.

| Element | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| A860 WPHY 60 | 415 | 515-690 | 28 % |

Carbon Steel A860 WPHY 60 Weld Lateral Tee

High Yield Carbon Steel A860 WPHY 60 End Cap

ASTM A860 Carbon Steel 60 Reducing Tee

ASTM A860 High Yield Gr WPHY 60 Stub Ends

Buttweld WPHY-60 Concentric Reducer

MSS SP 75 WPHY 60 Eccentric Reducer

ASTM A860 Gr WPHY 60 45 Degree Elbow

Carbon Steel MSS SP75 60 90 Deg Elbow

A860 Carbon Steel 60 Equal Tee

A860 Gr 60 180 Deg Elbow

WPHY 60 BW Cross Fitting

MSS SP 75 60 Material

4. Buttweld-WPHY 60 SMLS CAP

MSS SP 75 WPHY 60 cap

Cap Pipe fittings

5. A860 Carbon Steel WPHY 60 Stubend

A860 Carbon Steel WPHY 60 Stubend

these Material ASTM A860 Buttweld are known for accurate dimension, corrosion resistance and durability.

A860 Gr WPHY 60 Short Stubend

A860 Carbon Steel WPHY 60 BW Long Stubend

3.ASTM A860 MSS SP 75 60 Reducer

WT: sch40/ std/ sch80/ thick-wall

Carbon Steel Grade WPHY 60 Pipe Concentric

A860 WPHY 60 Eccentric Reducer

MSS SP 75 A860 60 Con/ Ecc Reducer

ASTM A860 API 5L X60 elbow manufacturer