-

-

send us mail

[email protected]

This standard covers factory produced seamless as well as electric fusion-welded MSS SP-75 Fittings. The materials used to manufacturer these fittings are usually carbon steel or low-alloy steel grades, depending on the application. Typically the butt-welding pipe fittings such as MSS SP 75 Tee are designed with the intention of being used in not only high pressure oil and gas transmission and distribution systems, but they are also used in other systems including compressor stations, pipelines, metering and regulating stations, as well as mains.

MSS SP-75 Fittings

Buttweld MSS SP-75 Elbow

A860 MSS SP 75 Material

Specification MSS SP 75 is a standard for high-test, wrought grade butt-welded fittings for e.g. 3R elbows, long-radius elbows, reducing tees, straight tees, caps and reducers.

| MSS SP 75 Class | Yield Strength | Tensile Strength | Elongation | Charpy Test |

|---|---|---|---|---|

| Min. psi | Min. psi | min. % | Ave. Energy absorbed @ 20°F | |

| 42000 | 60000 | 25 | ≥20ft*lbs | |

| WPHY 46 | 46000 | 63000 | 25 | |

| ASTM A860 WPHY 52 | 52000 | 66000 | 25 | |

| ASTM A860 WPHY 56 | 56000 | 71000 | 20 | |

| ASTM A860 WPHY 60 | 60000 | 75000 | 20 | |

| ASTM A860 WPHY 65 | 65000 | 77000 | 20 | |

| ASTM A860 WPHY 70 | 70000 | 82000 | 18 |

| Standard Specification : | MSS SP-75 Fittings |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Application: | Nuclear Power Plant Natural Gas Industry Water Pipeline Industry Fabrication Industry Chemical Industry Oil And Gas Industry |

| Coating Fitting Faces : | Oil Black Paint, Cold and Hot Dip Galvanized, Zinc Plated, Anti-rust Paint, Yellow Transparent |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

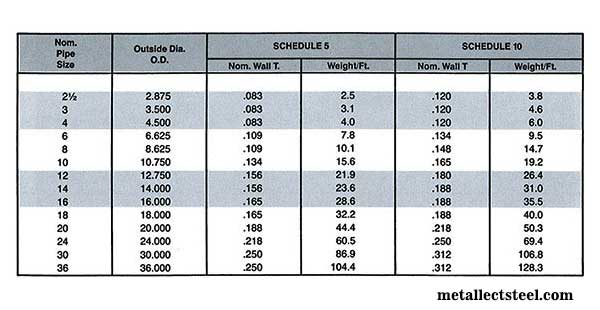

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | JIS B2313, ANSI B16.9, MSS-SP-43 Type b, ANSI B16.28, JIS B2312, MSS-SP-43 Type A |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Fitting Machining Equipment: | Bending machine, Electric bevelling machine, Pushing Machine, Press machine, Sand-blasting machine etc |

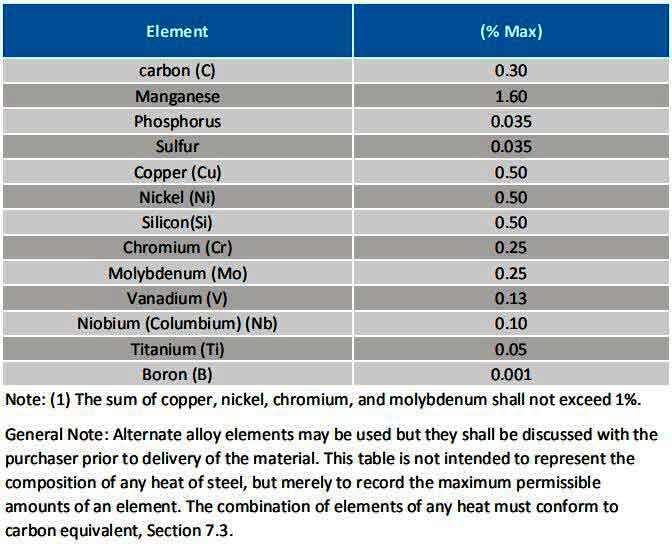

Based on their yield strength values, the MSS SP 75 Weld Fittings are categorized into 7 different WPHY classes i.e 42, 46, 52, 56,60, 65 and 70. The term WPHY is always associated with MSS SP 75 specified fitting. The term is split into 2 different parts where WP has been abbreviated as either wrought pipe or wrought plate, while HY is an abbreviation for high yield components for e.g. MSS SP 75 Pipe Reducers. The MSS SP 75 is a standard that specifies the chemical composition, A860 MSS SP 75 Material and tensile properties, dimensions, tolerances, ratings, heat treatment, notch toughness as well as manufacturing process and marking of quality butt welded pipe fittings for pipes that have a diameter of NPS 60 and smaller. Keeping in accordance with the MSS SP-75 standard, all fittings including the Buttweld MSS SP-75 Elbow manufactured are required to be designed in such a manner that they support the field hydrostatic pressure test at a certain pressure level.

| MSS SP-75 Fittings Pressure Rating | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | |||||||

| (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | |||||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | |||

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | ||||

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | ||||

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | |||

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | ||||

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | ||||

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | |||

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | ||||

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | ||||

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | |||

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | ||||

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | ||||

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | |||

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | ||||

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | ||||

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | |||

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | ||||

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | ||||

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | |||

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | ||||

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | ||||

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | |||

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | ||||

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | ||||

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | |||

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | ||||

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | ||||

MSS SP-75 Elbow

MSS SP-75 Tee

MSS SP-75 Reducer

MSS SP-75 End Cap

MSS SP-75 Stub End

MSS SP-75 Threaded Plug

MSS SP-75 Socket Weld Union

MSS SP-75 Cross

MSS SP-75 U Bend

MSS SP-75 Lateral Tee

| ANSI b16.9 fittings Sizes Nominal | ASME b16 9 Pipe Fitting Outside Diameter Y |

Wall Thickness T (Pipe Elbow Schedule) |

45 Deg Long Radius Elbow Centre to Face B | 45 Deg Short Radius Elbow Weight |

90 Deg Long Radiu Elbow Centre to Face A | 90 Deg Long Radiu Elbow Weight | 90 Deg Short Radius Elbow Centre to Face A | 90 Deg Short Radius Elbow Weight Chart | ||

| mm | in | mm | mm | Schedule | mm | kg | mm | kg | mm | kg |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 | |||