-

+91

-

send us mail

[email protected]

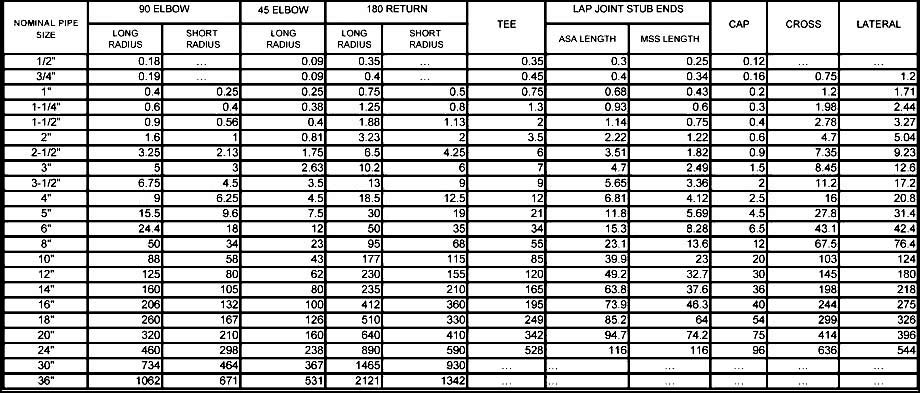

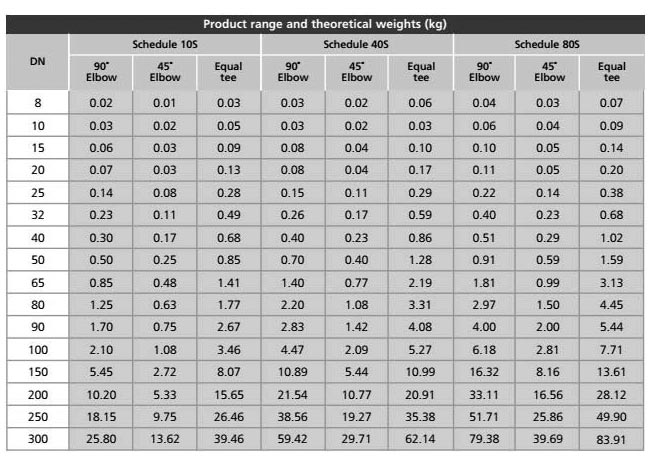

Factory made, wrought buttweld fittings are generally produced under standard ASME B16.9. Produced between size range NPS 1/2 through NPS 48, the Buttweld Pipe Fittings are required to conform to the overall dimensions, tolerances, ratings, testing, as well as markings as specified by the ASME B16.9. The construction of these fittings are either seamless or they could be welded. Usually, a welded constructed fitting is much cheaper in comparison to a seamless type. The seam present on the ASME B16.9 BW Welded Fittings could be reduced by performing a set of surface treatments in such a manner that it is hardly visible by naked eyes. The ends of a butt weld fittings could be either plain or beveled. The Seamless Buttweld Pipe Fittings envelopes various types of fittings including tee, reducer, elbow, cap, and lap joint stub end. In comparison to either socket weld or threaded fittings, the cost of a buttweld fitting is much lesser. Alloy steel, stainless steel and carbon steel fittings produced using a Seamless Welding Fittings Weight Chart are an important part of an industrial piping system, which could be applied to a piping system.

ASME B16.9 Buttweld Pipe Fittings

Seamless Buttweld Fittings

ANSI B16.9 BW Welded Fittings

90 Deg Elbow: 16 Inch NPS, Ecc Reducer: 8 Inch x 6 Inch NPS, Seamless, ASME B16.9, BW, Sch 40 x Sch 80, ASTM A403 F304 And A234 WPB

Several industries like the Chemical Industries, Machines and equipment, textiles, pulp and paper, Power stations, nuclear industry, Water treatment systems, Sanitary tubing, Heat Exchangers, sugar, food and beverage, oil and gas transmissions as well as petroleum and Oil refining etc are clients of every leading Buttweld Fittings Manufacturer In India. Most of these industries use Seamless Buttweld Fittings Dimensions to produce fitting, which then could be used to either change direction, branch off or to join equipment to the system mechanically.

| SR NO | Description | PRICE PAR PICE IN (USD$) |

| 1 | 6 in. Schedule 40, ASTM A403 304L, 45 Deg Elbow, Seamless, BW, Long Radius, ASME B16.9 | $54.56 |

| 2 | 90 Deg Elbow, 2 Inch To 8 Inch, Sch 40 * Sch 80, Buttweld, Seamless, Short Radius, ASTM WPB A234, ASME B16.9 | $62.78 |

| 3 | Con Reducer, 14 Inch x 8 Inch, 6NPS x 3NPS, Seamless, Sch 80 * Sch 120, Buttweld, ASTM A403 F316L, ASME B16.9 | $29.35 |

| 4 | Equal Tee, 1 inch Sch 80, 1 inch Sch 40, SMLS, BUttweld, ASME B16.9 | $38.67 |

| 5 | Reducing Cross: 12 NPS, Seamless, BUttweld, SCH20 * SCH40, ASME B16.9 | $16.98 |

Please note this is an approx Price of ASME B16.9 Buttweld Pipe Fitting in Nagpur, India. For final Seamless Butt weld pipe fitting Price List Please Call on Send Us Mail or drop an Email to [email protected].

| Specification : | ASME B16.9 Buttweld Pipe Fittings |

| Connection Type : | Welding |

| Buttweld Fittings Industries For Use : | Nuclear Power Plant Oil And Gas Industry Petrochemical Industry |

| Buttweld Fittings Sizes: | SLMS BW Pipe Fittings: To 1/2″ – 10″ Welded / Seamless : To 1/2″ – 48″ |

| Type : | ERW / SMLS / Welded / BW / Fabricated |

| Manufacturers Process : | Push, Press, forge, Cast, Marking, Packing In Boxes For Sale. |

| Bending Radius : | Radius = 1D, 2D, 3D, 5D, 6D, 8D, 10D |

| Size Range : | ½" NB to 24" NB in Sch10s * Sch40s * Sch80s * Sch160s |

| All Standard Of ASME B16.9 Seamless Fittings: | JISB2311, IS 2062, PN, AWWA C207, BS4504, BS1560, BS, GB, ISO, ASME B16.9, BS10, ASME B16.47, ASME B16.38, MSS-SP-43, DIN, ANSI B16.28, DIN2605, JISB2312, JISB2313, ASME B16.25, MSS SP-75 |

| Mills And Origin : | Russian, India, Japanese, USA, UAE |

| Welding Fittings Thickness :: | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140 |

ASTM A403 WP304 Buttweld Fittings

ASME B16.9 Butt-Welding Pipe Fittings

2 Inch * 8 Inch Seamless Butt Weld Pipe Fittings

SCh 40 Seamless Fittings

A403 304 Buttweld Seamless Marine Fittings

4 Inch Flanged Sch 10 Seamless Welding Fittings

1-1/2 inch Butt Weld Seamless Buttweld Fittings

18 inch Sch 40 Seamless Buttweld Pipe Fittings

Aluminum Butt Weld Fittings

A234 WPB Mild Steel Buttweld Fittings

Carbon Steel WPHY 60 Butt Weld Tube Fittings

Elbow Seamless Pipe Fittings

| Elbow Fitting NPS | Elbow Fitting Outside Diameter Y |

Wall Thickness T (Pipe Elbow Schedule) |

45 Degree Elbow Long Radius Centre to Face B | 45 Degree Elbow Long Radius Weight |

90 Degree Elbow Long Radius Centre to Face A | 90 Degree Elbow Long Radius Weight | 90 Degree Elbow Short Radius Centre to Face A | 90 Degree Elbow Short Radius Weight | ||

| MilliMeter | InCh | MilliMeter | MilliMeter | Sch | MilliMeter | KiloGram | MilliMeter | KiloGram | MilliMeter | KiloGram |

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | – | – |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | – | – | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | – | – |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | – | – | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 |

| Tolerances Of ASME B16.9 Seamless Welding Fittings Tolerance (45, 90, 180 Long And Short Radius Elbow, Pipe Cap, Reducing Tee, Con, Ecc Reducer) | 90 Degree & 45 Degree Pipe Elbow and Tee |

Reducer Fittings & Lap Joint Stub End |

Pipe End Cap | |||

| Dimension BW Fittings (Normal Pipe Size) | Outside Diameter at Bevel |

Inside Diameter at End |

WallThickness T | Center-to-End Dimension A ,C ,B |

Over-all Length H |

Over-all Length F |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.06 | +/- 0.06 | +/- 0.12 | |

| -0.03 | ||||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 to 18 | +0.16 | +/- 0.12 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.12 | ||||||

| 20 to 24 | +0.25 | +/- 0.19 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.19 | ||||||

| 26 to 30 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

| 32 to 48 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

| Asme B16.9 Fittings Materials Comparison Chart | ||

|---|---|---|

| Werkstoff Or DIN Number | European Grade | ASTM/ ASME Grade |

| Carbon Steel Pipe Fittings Grades | ||

| Werkstoff 1.0405 St 45.8/I | P265GH (1.0425) | A234 Grade WPB Pipe Fittings |

| Werkstoff 1.0405 St 45.8/III | P265GH (1.0425) | |

| Alloy Steel Pipe Fittings Grades | ||

| Werkstoff No. 1.5415 15 Mo 3 | 16Mo3 | SA234 Grade WP1 Fittings |

| Werkstoff No. 1.7335 13 CrMo 4 4 | 13CrMo4-5 | A234 Grade WP11, WP12 Fittings |

| Werkstoff No. 1.7380 10 CrMo 9 10 | 10CrMo9-10 | ASME SA234 Grade WP22 Fittings |

| Werkstoff No. 1.7362 12 CrMo 19 5 | X11CrMo5 | ASME SA234 Grade WP5 Fittings |

| LTCS (Low Temperature Carbon Steel) Fittings Grade | ||

| Werkstoff No. 1.5637 10 Ni 14 | 12Ni14 | ASME SA420 Grade WPL3 Fittings |

| Werkstoff No. 1.0356 TTSt 35 N | P215NL (1.0451) | – |

| ASME SA420 Grade WPL6 Fittings | ||

| High Yield Carbon Steel Fittings Grade | ||

| 1.0486 StE 285 | A860 WPHY42 | |

| Werkstoff No. 1.0562 StE 355 | P355N | A860 WPHY52 Pipe Fitting |

| Werkstoff No. 1.8902 StE 420 | A860 WPHY60 Fitting | |

| Werkstoff No. 1.8905 StE 460 | A860 WPHY70 Fitting | |

| Stainless Steel Buttweld Fittings Grade | ||

| Werkstoff No. 1.4541 X 6 CrNiTi 18 10 | X6CrNiTi18-10 | ASME SA403 WP321 Fitting |

| Werkstoff No. 1.4301 X 5 CrNi 18 10 | X5CrNi18-10 | ASME SA403 WP304 Fitting |

| Werkstoff No. 1.4306 X 2 CrNi 19 11 | X2CrNi19-11 | ASTM A403 WP304L Fitting |

| Werkstoff No. 1.4401 X 5 CrNiMo 17 12 2 | X5CrNiMo17-12-2 | ASTM A403 WP316 Fittings |

| Werkstoff No. 1.4404 X 2 CrNiMo 17 13 2 | X2CrNiMo17-12-2 | ASME SA403 WP316L Fittings |

| Werkstoff No. .4462 X 2 CrNiMoN 22 5 3 | X2CrNiMoN22-5-3 | UNS S 31803 (Duplex) Fittings |

| Buttweld Pipe fittings Pressure (psig) | |||||

|---|---|---|---|---|---|

| Temperature Ratings | Pressure Class | ||||

| Class 150 | Class 300 | ||||

| 1/4 - 1 Inches | 1 1/4 - 2 Inches | 2 1/2 - 3 Inches | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

| (NPS) Normal Pipe Size | (O.D.) Outside Diameter | Ave. (I.D.) Inside Daimeter |

Minimum WALL |

Normal Weight Chart In KG |

Maximum W.P. psi |

| 1/4" | .540 | .344 | .088 | .086 | 780 |

| 3/8" | .675 | .473 | .091 | .115 | 620 |

| 1/2" | .840 | .602 | .109 | .170 | 590 |

| 3/4" | 1.050 | .804 | .113 | .226 | 480 |

| 1" | 1.315 | 1.029 | .133 | .333 | 450 |

| *1-1/4" | 1.660 | 1.360 | .140 | .450 | 370 |

| *1-1/2" | 1.900 | 1.590 | .145 | .537 | 330 |

| *2" | 2.375 | 2.047 | .154 | .720 | 280 |

| 2-1/2" | 2.875 | 2.445 | .203 | 1.136 | 300 |

| *3" | 3.500 | 3.042 | .216 | 1.488 | 260 |

| 3-1/2" | 4.000 | 3.521 | .226 | 1.789 | 240 |

| *4" | 4.500 | 3.998 | .237 | 2.118 | 220 |

| 5" | 5.563 | 5.016 | .258 | 2.874 | 190 |

| *6" | 6.625 | 6.031 | .280 | 3.733 | 180 |

| *8" | 8.625 | 7.942 | .322 | 5.619 | 160 |

| *10" | 10.750 | 9.976 | .365 | 7.966 | 140 |

| *12" | 12.750 | 11.889 | .406 | 10.534 | 130 |

| *14" | 14.000 | 13.073 | .437 | 12.462 | 130 |

| *16" | 16.000 | 14.940 | .500 | 16.286 | 130 |

| *18" | 18.000 | 16.809 | .562 | 20.587 | 130 |

| *20" | 20.000 | 18.743 | .593 | 24.183 | 120 |

| *24" | 24.000 | 22.544 | .687 | 33.652 | 120 |

| (NPS) Normal Pipe Size | (O.D.) Outside Diameter | Ave. (I.D.) Inside Diameter |

minimum WALL |

Normal Weight In KG |

Maxium W.P. psi |

| 1/4" | .540 | .282 | .119 | .105 | 1130 |

| 3/8" | .675 | .403 | .126 | .146 | 920 |

| 1/2" | .840 | .526 | .147 | .213 | 850 |

| 3/4" | 1.050 | .722 | .154 | .289 | 690 |

| 1" | 1.315 | .936 | .179 | .424 | 630 |

| 1-1/4" | 1.660 | 1.255 | .191 | .586 | 520 |

| 1-1/2" | 1.900 | 1.476 | .200 | .711 | 470 |

| 2" | 2.375 | 1.913 | .218 | .984 | 400 |

| 2-1/2" | 2.875 | 2.290 | .276 | 1.500 | 420 |

| 3" | 3.500 | 2.864 | .300 | 2.010 | 370 |

| 3-1/2" | 4.000 | 3.326 | .318 | 2.452 | 350 |

| 4" | 4.500 | 3.786 | .337 | 2.938 | 320 |

| 5" | 5.563 | 4.768 | .375 | 4.078 | 290 |

| 6" | 6.625 | 5.709 | .432 | 5.610 | 280 |

| 8" | 8.625 | 7.565 | .500 | 8.522 | 250 |

| 10" | 10.750 | 9.493 | .593 | 12.635 | 230 |

| 12" | 12.750 | 11.294 | .687 | 17.384 | 230 |

| 14" | 14.000 | 12.410 | .750 | 20.852 | 220 |

| 16" | 16.000 | 14.213 | .843 | 26.810 | 220 |

| 18" | 18.000 | 16.014 | .937 | 33.544 | 220 |

| 20" | 20.000 | 17.814 | 1.031 | 41.047 | 220 |

| 24" | 24.000 | 21.418 | 1.218 | 58.233 | 210 |

| Element | Content (%) |

| Phosphorous | 0.045 |

| Silicon | 1 |

| Carbon | 0.03 |

| Sulfur | 0.03 |

| Chromium | 18-20 |

| Nickel | 11-15 |

| Molybdenum | 3-4 |

| Iron, Fe | Balance |

| Manganese | 2 |

| Properties | Metric | Imperial |

| Elongation at break (in 50 mm) | 55% | 55% |

| Tensile strength | 595 MPa | 86300 psi |

| Hardness, Rockwell B | 85 | 85 |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Yield strength | 260 MPa | 37700 psi |

| Modulus of elasticity | 200 GPa | 29000 ksi |