-

-

send us mail

[email protected]

Aside from forging connections, the secondary function of a DIN 2576 PN10 Flange is to provide easy access to a worker into the said piping systems. Over a period of time, every piping system is required to undergo regular checks and upkeep for a smooth and efficient flow of media. Essentially a Carbon Steel DIN 2576 pn10 flange is a means that the worker could use to either inspect, change or modify and clean a piping system.

Flanges are a medium of forging connections between pipes, valves, pumps and other equipment in a piping system.

This being said, there are different kinds of flanges which perform different tasks. For instance, a Flat Flange Din 2576 pn10 is typically used in piping systems that have low pressure and in low temperature environments such as water treatment or pump suction flanges, especially since, the piping or piping components in these systems tend to be brittle on account if being made from either plastic, fibreglass or cast iron. On the other hand, a DIN 2576 Pn10 Slip On Flanges Dimension finds particular use due to its smaller thickness which provides easier alignment of bolting holes. Moreover, slip-on flanges tend to be leak-proof and the Installation cost for a Stainless Steel DIN 2576 Flange slip on type is low. Apart from carbon steel, the Din 2576 Flange Material could include alloys such as Monel, Nickel, Inconel, Incoloy, Hastalloy, Titanium, Duplex Steel as well as Alloy Steel.

| Specification : | DIN 2576 PN10 Flange |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Common Types of Flanges Dimensions: | Class 150 RTJ Flanges 300 LB WNRF Class 900 SORF 1500# BLRF Class 2500 BLRF |

| Production Process: | Forged, Heat Treated and Machined |

| Coating Flanges Faces : | Yellow Transparent, Cold and Hot Dip Galvanized, Zinc Plated, Oil Black Paint, Anti-rust Paint |

| Design For Size: | EN, ASA, PN, JIS, BS, ANSI, ASME, DIN |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Standard : | ASME B16.38 Flange, ISO Flange, JIS Flange, DIN Flange, PN Flange, MSS SP44 Flange, EN-1092 Flange, BS10 Flange, ASME B16.47 (Series A, Series B) Flange, UNI Flange, ASME B16.5 Flange, AWWA Flange, GOST Flange |

| Machining Equipment: | Bending machine, Sand-blasting machine, Press machine, Pushing Machine, Electric bevelling machine etc |

| Application: | Natural Gas Industry Nuclear Power Plant Chemical Industry Oil And Gas Industry Water Pipeline Industry Fabrication Industry |

| Supporting Flanges Material: | Flanges Bolts, Gasket, Ring Joint |

| Connect Type Type: | FF, RTJ, SMF, LMF, RF, LJF |

DIN 2576 Pn10 Slip On Flange

Stainless Steel Flanges DIN 2576

Flat Flange DIN 2576 pn10

Flanges Norma Din 2576 Pn10

DIN 2576 PN10 Plate Flange

DIN 2576 PN 10 Form B Flange

DIN 2576 PN 10 DN 700 Plate Flange

DIN 2576 PN 10 DN 300 Flange

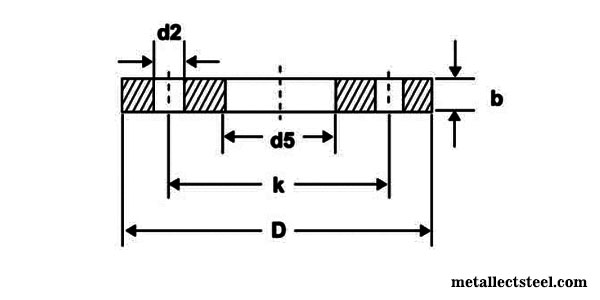

| NPS | Diam. of Pipe | Flange Dimension | Nuts & Bolts | Appro. Flange Weight Table | |||||

| Flanges I.D | Flanges Dia | Thickness of Flanges | Diameter of Bolt Circle | Number of Holes | Diameter of Bolt Holes | ||||

| DN | ISO | DIN | d5 | D | b | k | d2 | KG /PCS | |

| 10 | - | 14 | 14.5 | 90 | 14 | 60 | 4 | 14 | 0.61 |

| 17.2 | - | 17.7 | 90 | 14 | 60 | 4 | 14 | 0.6 | |

| 15 | - | 20 | 21 | 95 | 14 | 65 | 4 | 14 | 0.67 |

| 21.3 | - | 22 | 95 | 14 | 65 | 4 | 14 | 0.67 | |

| 20 | - | 25 | 26 | 105 | 16 | 75 | 4 | 14 | 0.94 |

| 26.9 | - | 27.6 | 105 | 16 | 75 | 4 | 14 | 0.94 | |

| 25 | - | 30 | 31 | 115 | 16 | 85 | 4 | 14 | 1.13 |

| 33.7 | - | 34.4 | 115 | 16 | 85 | 4 | 14 | 1.11 | |

| 32 | - | 38 | 39 | 140 | 16 | 100 | 4 | 18 | 1.66 |

| 42.4 | - | 43.1 | 140 | 16 | 100 | 4 | 18 | 1.62 | |

| 40 | - | 44.5 | 45.5 | 150 | 16 | 110 | 4 | 18 | 1.89 |

| 48.3 | - | 49 | 150 | 16 | 110 | 4 | 18 | 1.85 | |

| 50 | - | 57 | 58.1 | 165 | 18 | 125 | 4 | 18 | 2.5 |

| 60.3 | - | 61.1 | 165 | 18 | 125 | 4 | 18 | 2.46 | |

| 65 | 76.1 | - | 77.1 | 185 | 18 | 145 | 4 | 18 | 2.99 |

| 80 | 88.9 | - | 90.3 | 200 | 20 | 160 | 8 | 18 | 3.61 |

| 100 | - | 108 | 109.6 | 220 | 20 | 180 | 8 | 18 | 4.17 |

| 114.3 | - | 115.9 | 220 | 20 | 180 | 8 | 18 | 3.99 | |

| 125 | - | 133 | 134.8 | 250 | 22 | 210 | 8 | 18 | 5.66 |

| 139.7 | - | 141.6 | 250 | 22 | 210 | 8 | 18 | 5.41 | |

| 150 | - | 159 | 161.1 | 285 | 22 | 240 | 8 | 22 | 6.97 |

| 168.3 | - | 170.5 | 285 | 22 | 240 | 8 | 22 | 6.55 | |

| 175 | 193.7 | - | 196.1 | 315 | 24 | 270 | 8 | 22 | 8.42 |

| 200 | 219.1 | - | 221.8 | 340 | 24 | 295 | 8 | 22 | 9.28 |

| 250 | - | 267 | 270.2 | 395 | 26 | 350 | 12 | 22 | 12.36 |

| 273 | - | 276.2 | 395 | 26 | 350 | 12 | 22 | 11.85 | |

| 300 | 323.9 | - | 327.6 | 445 | 26 | 400 | 12 | 22 | 13.61 |

| 350 | 355.6 | - | 359.7 | 505 | 28 | 460 | 16 | 22 | 20.35 |

| - | 368 | 372.2 | 505 | 28 | 460 | 16 | 22 | 18.77 | |

| 400 | 406.4 | - | 411 | 565 | 32 | 515 | 18 | 26 | 27.52 |

| - | 419 | 423.7 | 565 | 32 | 515 | 18 | 26 | 35.43 | |

| 450 | 457 | - | 462.3 | 615 | 38 | 565 | 20 | 26 | 35.11 |

| 500 | 508 | - | 613.6 | 670 | 38 | 620 | 20 | 26 | 40.2 |

| 600 | 610 | - | 615.5 | 780 | 40 | 725 | 20 | 26 | 51.87 |

| Temperature (in F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test (psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

| NPS NPS (inch) |

|||||

|---|---|---|---|---|---|

| Diammeter of Flange (inch) |

No. of Bolts |

Diammeter of Bolts (inch) |

Diammeter of Bolt Holes (inch) |

Bolt Circle (inch) |

|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |