-

-

send us mail

[email protected]

Standard DIN 2543 is a specification that takes into account different flanges produced in different alloy grades in varying pressure classes. In this instance, PN16 Flange is indicative of its working pressure in bars. Similar to many of the common flange standards, that are used across several industries globally, the DIN 2543 PN16 Plate Flange Dimension is designed to have a standardized set of dimensions, which in turn permits easy interchangeability as well as functionality.

DIN, which stands for Deutsches Industrie Normen is a German Industrial Standards.

The flanges with the dimensions of the DIN 2543 PN16 Standards are to be used at a maximum temperature of about 120°C with up to a working pressure of 16 bar. At a higher temperature range between 120°C to 300°C, a point to be noted is that the yield point of the Carbon Steel DIN 2543 pn16 flanges Material tends to become lower. PN has been derived from the acronym of the French word Pressure Nominale, which is translated as Nominal Pressure. Pn is the official pressure rating as opposed to the actual pressure capability of the component, which in this case is the Stainless Steel DIN 2543 pn16 flange. Usually, a Din 2543 Pn16 Slip On Flange is used in applications that deal with both low pressure and low temperature.

| Specification : | DIN 2543 PN16 Flanges |

| Design For Size: | JIS, BS, ANSI, ASME, EN, ASA |

| Production Process: | Forged, Heat Treated and Machined |

| Application: | Fabrication Industry Oil And Gas Industry Natural Gas Industry Chemical Industry Water Pipeline Industry Nuclear Power Plant |

| Connect Type Type: | SMF, LMF, RF, LJF, FF, RTJ |

| Standard : | MSS SP44 Flange, BS10 Flange, ASME B16.47 (Series A, Series B) Flange, UNI Flange, ASME B16.38 Flange, ISO Flange, JIS Flange, EN-1092 Flange, ASME B16.5 Flange, AWWA Flange, GOST Flange |

| Supporting Flanges Material: | Flanges Bolts, Gasket, Ring Joint |

| Machining Equipment: | Press machine, Pushing Machine, Electric bevelling machine, Bending machine, Sand-blasting machine etc |

| Coating Flanges Faces : | Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated, Oil Black Paint, Yellow Transparent |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Common Types of Flanges Dimensions: | Class 150 RTJ Flanges 300 LB WNRF Class 900 SORF 1500# BLRF Class 2500 BLRF |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

Din 2543 Pn16 Slip On Flange

DIN 2543 PN16 Plate Flange

Stainless Steel Din 2543 PN16 Flange

DIN 2543 16 DN 300 Flange

Flat Flanges Din 2543 PN16

Alloy Steel DIN 2543 pn16 flange

Flange DIN 2543 PN16

DIN SS 2543 pn16 Flange

| Bore | Comm. Dimension | RF | Drilling | Appr. Weight (Kilogram) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

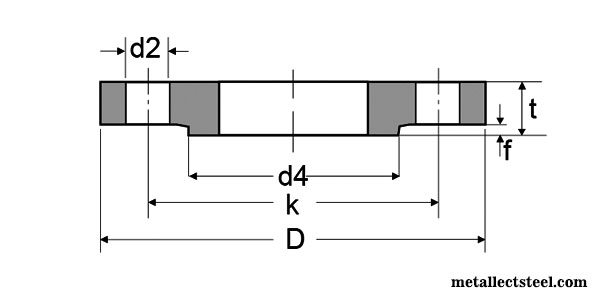

| Nominal Bore | d1 | D | t | K | d4 | f | No. of Bolts | x | d2 | DIN 2543 | |

| 10 | 14 | 90 | 14 | 60 | 40 | 2 | 4 | M12 | (1/2") | 14 | 0.63 |

| 17.2* | |||||||||||

| 15 | 20 | 95 | 14 | 65 | 45 | 2 | 4 | M12 | (1/2") | 14 | 0.72 |

| 21.3* | |||||||||||

| 20 | 25 | 105 | 16 | 75 | 58 | 2 | 4 | M12 | (1/2") | 14 | 1.01 |

| 26.9* | |||||||||||

| 25 | 30 | 115 | 16 | 85 | 68 | 2 | 4 | M12 | (1/2") | 14 | 1.23 |

| 33.7* | |||||||||||

| 32 | 38 | 140 | 16 | 100 | 78 | 2 | 4 | M16 | (5/8") | 18 | 1.80 |

| 42.4* | |||||||||||

| 40 | 44.5 | 150 | 16 | 110 | 88 | 3 | 4 | M16 | (5/8") | 18 | 2.09 |

| 48.3* | |||||||||||

| 50 | 57 | 165 | 18 | 125 | 102 | 3 | 4 | M16 | (5/8") | 18 | 2.88 |

| 60.3* | |||||||||||

| 65 | 76.1* | 185 | 18 | 145 | 122 | 3 | 4 | M16 | (5/8") | 18 | 3.66 |

| 80 | 88.9 | 200 | 20 | 160 | 138 | 3 | 8 | M16 | (5/8") | 18 | 4.77 |

| 100 | 108 | 220 | 20 | 180 | 158 | 3 | 8 | M16 | (5/8") | 18 | 5.65 |

| 114.3* | |||||||||||

| 125 | 133 | 250 | 22 | 210 | 188 | 3 | 8 | M16 | (5/8") | 18 | 8.42 |

| 139.7* | |||||||||||

| 150 | 159 | 285 | 22 | 240 | 212 | 3 | 8 | M20 | (3/4") | 23 | 10.4 |

| 168.3* | |||||||||||

| 200 | 216 | 340 | 24 | 295 | 268 | 3 | 12 | M20 | (3/4") | 23 | 16.1 |

| 219.1* | |||||||||||

| 250 | 267 | 405 | 26 | 355 | 320 | 3 | 12 | M24 | (7/8") | 27 | 24.9 |

| 273* | |||||||||||

| 300 | 318 | 460 | 28 | 410 | 378 | 4 | 12 | M24 | (7/8") | 27 | 35.1 |

| 323.9* | |||||||||||

| 350 | 355.6* | 520 | 30 | 470 | 438 | 4 | 16 | M24 | (7/8") | 27 | 47.8 |

| 368 | |||||||||||

| 400 | 406.4* | 580 | 32 | 525 | 490 | 4 | 16 | M27 | (1") | 30 | 63.5 |

| 419 | |||||||||||

| 500 | 508* | 715 | 36 | 650 | 610 | 4 | 20 | M30 | (1-1/8") | 33 | 102.0 |

| 521 | |||||||||||

| Temperature (in F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test (psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

| NPS NPS (inch) |

|||||

|---|---|---|---|---|---|

| Diammeter of Flanges (inch) |

No. of Bolts |

Diammeter of Bolts (inch) |

Diammeter of Bolt Holes (inch) |

Bolt Circle (inch) |

|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |