-

-

send us mail

[email protected]

One such product specification is the DIN 2501 PN16 Flange. This specification covers several aspects of the flanges, which could be used to either manufacture, check or buy these flanges. Which means the DIN 2501 standard covers materials, DIN 2501 PN16 Slip On Flange Dimensions, tolerances, marking, as well as pressure-temperature ratings, testing. Not forgetting the methods of designating openings for pipe flanges and flanged fittings, which are also covered by the DIN 2501 standard. Therefore if a buyer requires flanges that have exceptional corrosion resistance properties, with increased mechanical strength and heat resisting properties, he could choose to purchase a Stainless Steel DIN 2501 pn16 flange. This being said, since there are various stainless steel grades available in the market, he could choose that particular alloy which could be well suited for the application it is intended for.

Similar to many other international bodies, the DIN or German Institue of Standardization has listed out a set of specifications for use across European countries.

If required, the buyers also have a choice to order different surface treatments for the DIN 2501 PN16 Plate Flange or he could have them delivered bare i.e. without any finish. There are several kinds of flanges available in the market. Typically a Flat Flange Din 2501 pn16 is a device that is used to forge a connection between piping systems in addition to forming connections with equipment, pumps or valves. The PN value mentioned on the flange is indicative of the pressure it can withstand. Hence, a flanges norma din 2576 pn16 has the ability to withstand a Nominal Pressure of approx 16 bar.

| Specification : | DIN 2501 PN16 Flange |

| Standard : | BS10 Flange, ASME B16.47 (Series A, Series B) Flange, UNI Flange, ASME B16.38 Flange, ISO Flange, JIS Flange, MSS SP44 Flange, EN-1092 Flange, ASME B16.5 Flange, AWWA Flange, GOST Flange |

| Machining Equipment: | Press machine, Pushing Machine, Electric bevelling machine, Bending machine, Sand-blasting machine etc |

| Coating Flanges Faces : | Cold and Hot Dip Galvanized, Yellow Transparent, Zinc Plated, Oil Black Paint, Anti-rust Paint |

| Design For Size: | BS, ANSI, ASME, EN, ASA, JIS |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Production Process: | Forged, Heat Treated and Machined |

| Application: | Chemical Industry Nuclear Power Plant Natural Gas Industry Fabrication Industry Water Pipeline Industry Oil And Gas Industry |

| Supporting Flanges Material: | Ring Joint, Flanges Bolts, Gasket |

| Connect Type Type: | LMF, RF, LJF, FF, RTJ, SMF |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Common Types of Flanges Dimensions: | Class 150 RTJ Flanges 300 LB WNRF Class 900 SORF 1500# BLRF Class 2500 BLRF |

DIN 2501 PN16 Slip On Flange

DIN 2501 PN16 Plate Flange

Flat Flange DIN 2501 pn16

Flanges norma din 2576

Carbon Steel DIN 2576 pn16 flange

DIN 2576 PN 16 Form B Flange

DIN 2576 DN 300 Flange

DIN 2501 PN16 Blind Flanges

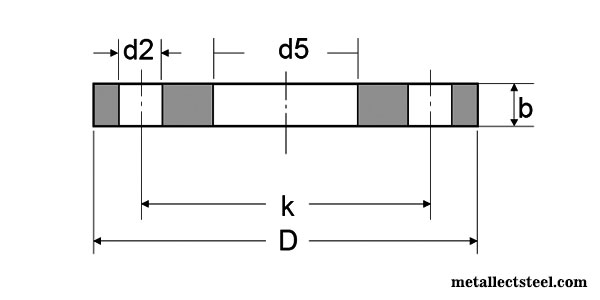

| NPS | Diam. of | Flanges Diammeter | Flanges I.D | Thickness of Flanges | f | Diameter of Bolt Cirlce | Number of | Diameter of Bolt Holes | Weight | |

|---|---|---|---|---|---|---|---|---|---|---|

| PLATE | BLIND | |||||||||

| DN | Pipe | D | D5 | B | K | holes | D2 | KG | KG | |

| 15 | 21.30 | 95 | 22.00 | 14 | 2 | 65 | 4 | 14 | 0.67 | 0.71 |

| 20 | 26.90 | 105 | 27.60 | 16 | 2 | 75 | 4 | 14 | 0.93 | 1.01 |

| 25 | 33.70 | 115 | 34.40 | 16 | 2 | 85 | 4 | 14 | 1.11 | 1.23 |

| 32 | 42.40 | 140 | 43.10 | 16 | 2 | 100 | 4 | 18 | 1.62 | 1.81 |

| 40 | 48.30 | 150 | 49.00 | 16 | 3 | 110 | 4 | 18 | 1.85 | 2.09 |

| 50 | 60.30 | 165 | 61.10 | 18 | 3 | 125 | 4 | 18 | 2.46 | 2.88 |

| 65 | 76.10 | 185 | 77.10 | 18 | 3 | 145 | 4 | 18 | 2.99 | 3.65 |

| 80 | 88.90 | 200 | 90.30 | 20 | 3 | 160 | 8 | 18 | 3.61 | 4.61 |

| 100 | 114.30 | 220 | 115.90 | 20 | 3 | 180 | 8 | 18 | 3.99 | 5.65 |

| 125 | 139.70 | 250 | 141.60 | 22 | 3 | 210 | 8 | 18 | 5.41 | 8.13 |

| 150 | 168.30 | 285 | 170.50 | 22 | 3 | 240 | 8 | 22 | 6.55 | 10.44 |

| 175 | 193.70 | 315 | 196.10 | 24 | 3 | 270 | 8 | 22 | 8.42 | |

| 200 | 219.10 | 340 | 221.80 | 24 | 3 | 295 | 12 | 22 | 8.97 | 16.48 |

| 250 | 273.00 | 405 | 276.20 | 26 | 3 | 355 | 12 | 26 | 12.76 | 23.99 |

| 300 | 323.90 | 460 | 327.60 | 28 | 3 | 410 | 12 | 26 | 16.60 | 30.73 |

| 350 | 355.60 | 520 | 359.70 | 30 | 4 | 470 | 16 | 26 | 24.08 | 42.56 |

| 400 | 406.40 | 580 | 411.00 | 32 | 4 | 525 | 16 | 30 | 30.20 | 60.68 |

| 450 | 457.00 | 640 | 462.30 | 38 | 4 | 585 | 20 | 30 | 41.67 | 71.74 |

| 500 | 508.00 | 715 | 513.60 | 38 | 4 | 650 | 20 | 33 | 52.87 | 96.4 |

| 600 | 610.00 | 840 | 616.50 | 42 | 4 | 770 | 20 | 36 | 77.58 | 145.6 |

| 700 | 711.00 | 910 | 716.00 | 44 | 840 | 24 | 36 | 77.13 | ||

| 800 | 813.00 | 1025 | 818.00 | 50 | 950 | 24 | 39 | 106.35 | ||

| 900 | 914.00 | 1125 | 920.00 | 54 | 1050 | 28 | 39 | 125.39 | ||

| 1000 | 1016.00 | 1255 | 1022.00 | 60 | 1170 | 28 | 42 | 177.99 | ||

| Temperature (in F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test (psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

| NPS NPS (inch) |

|||||

|---|---|---|---|---|---|

| Diammeter of Flange (inch) |

No. of Bolts |

Diammeter of Bolts (inch) |

Diammeter of Bolt Holes (inch) |

Bolt Circle (inch) |

|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |