-

-

send us mail

[email protected]

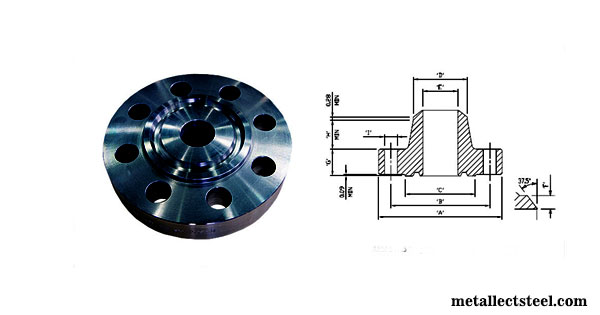

An RTJ or as referred to as ring joint type flange is positioned inside of the flanges bolts while surrounding the pipe bore. In a raised face design, the ASME B16.5 RTJ Flange sits on the raised surface. A benefit of RTJ flanges is that they could be installed without completely dissembling the joint, thereby making it a drop-in gasket. However, a Copper Nickel Rtj Reducing Flanges can also be difficult to clamp in position. Most manufacturers note that since the design requires less material, the cutting operations in comparison to most other fittings tend to be lesser.

Get RTJ Flanges, WN, 2" To 24", 150 RF, SCH 40 * SCH 120, Forged, ASTM A105. ASME B16.5 At Best Price.

When specifying a gasket of Class 900 Rtj Flange Dimensions only three measurements are required. Firstly, the ID or inner diameter which corresponds to the pipe bore; secondly, the OD or the outer diameter which is the same as the OD of the raised face; and lastly, gasket thickness. The ASME B16.5 - 1996 standard for Pipe Flanges and Flange Fittings standard envelopes temperature ratings, PN16 Ring Type Joint (Rtj) Flange Pressure Ratinge, materials, tolerances, dimensions, marking, testing, along with several methods of designating openings for these flanges and flanged fittings. The Standard is limited to flanges such as the ANSI B16.5 Ring Type Joint Flanges and flanged fittings produced from cast or forged material. Included in this Standard are requirements and recommendations regarding Stainless Steel RTJ Pipe Flange bolting, flanges gaskets flanges, and flanges joints.

| ASME B16.5 RTJ Flanges Pressure Ratings |

|||||||

| Temperature (F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Specification : | ASME B16.5 RTJ Flange |

| Design For Size: | ASA, ASME, DIN, PN, JIS, ANSI, BS, EN |

| Flange Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine, Press machine, electric bevelling machine etc |

| Flange Production Process: | Forged, Heat Treated and Machined |

| ASME B16.5 Flange Application: | Fabrication Industry Chemical Industry Water Pipeline Industry Natural Gas Industry Oil And Gas Industry Nuclear Power Plant |

| Coating Flange Faces : | Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated |

| ASA Flange Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Flange Standards : | ASME B16.5, ASME B16.47 (Series A, Series B), PN, JIS, ISO, ASME B16.38, EN-1092, BS10, DIN, GOST, UNI, AWWA, MSS SP44. |

| Connect Type Type: | RF, LMF, SMF, FF, RTJ, LJF. |

| Flange Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

ANSI 150LB Stainless Steel 304 Flange Rtj

A105 Flange BL Ring Type Joint Flange

ANSI B16.5 WN 2500# Rtj Flange

Mss Sp-44 A182 A240 F316 Rtj Reducing Flange

S32750 2 Inch 150LB ASME B16.5 Rtj Blind Flange

AWWA Flange DN80 PN16 Rtj Weld Neck Flange

ASME B16.5 Standard 150 LBS Rtj Threaded Flange

ASTM A694 F52 300# Rtj Orifice Flange

B16.5 600lbs 900 Lbs A694 F42 Rtj Slip On Flange

JIS 10K FF SS400 carbon Steel Rtj Pipe Flange

Carbon Steel A350 Lf2 Rtj Socket Weld Flange

ASME B16.5 A516 Gr.70 Class 1500 Rtj Flange

|

NPS |

Pitch Diameter of Ring and Groove |

Widthrongof Ring |

Height Of Ring |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of RF for Ring Joint or Lapped |

Ring No. |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

1 |

47.6 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

63.5 |

R15 |

4.1 |

|

1 1/4 |

57.2 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

73.2 |

R17 |

4.1 |

|

1 1/2 |

65.1 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

82.6 |

R19 |

4.1 |

|

2 |

82.6 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

101.6 |

R22 |

4.1 |

|

2 1/2 |

101.6 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

120.7 |

R25 |

4.1 |

|

3 |

114.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

133.4 |

R29 |

4.1 |

|

3 1/2 |

131.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

153.9 |

R33 |

4.1 |

|

4 |

149.2 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

171.5 |

R36 |

4.1 |

|

5 |

171.5 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

193.5 |

R40 |

4.1 |

|

6 |

193.7 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

218.9 |

R43 |

4.1 |

|

8 |

247.7 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

273.1 |

R48 |

4.1 |

|

10 |

304.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

330.2 |

R52 |

4.1 |

|

12 |

381.0 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

406.4 |

R56 |

4.1 |

|

14 |

396.9 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

425.5 |

R59 |

3.0 |

|

16 |

454.0 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

482.6 |

R64 |

3.0 |

|

18 |

517.5 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

546.1 |

R68 |

3.0 |

|

20 |

558.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

596.9 |

R72 |

3.0 |

|

24 |

673.1 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

711.2 |

R76 |

3.0 |

|

NPS |

Pitch Diameter of Ring and Groove |

Widthrong>of Ring |

Height Of Ring |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of RF for Ring Joint or Lapped |

Ring No. |

Appro. Distande Between Flange of Ring Joints When Ring is Compressed |

|||

|

OVal |

Octagonal |

|||||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

Class 300 |

Class 400 |

Class 600 |

||

|

1/2 |

34.1 |

6.4 |

11.1 |

9.5 |

4.3 |

7.1 |

5.6 |

50.8 |

R11 |

3.0 |

– |

3.0 |

|

3/4 |

42.9 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

63.5 |

R13 |

4.1 |

– |

4.1 |

|

1 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

69.9 |

R16 |

4.1 |

– |

4.1 |

|

1 1/4 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

79.5 |

R18 |

4.1 |

– |

4.1 |

|

1 1/2 |

68.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

90.4 |

R20 |

4.1 |

– |

4.1 |

|

2 |

82.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

108.0 |

R23 |

5.6 |

– |

4.8 |

|

2 1/2 |

101.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

127.0 |

R26 |

5.6 |

– |

4.8 |

|

3 |

123.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

146.1 |

R31 |

5.6 |

– |

4.8 |

|

3 1/2 |

131.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

158.8 |

R34 |

5.6 |

– |

4.8 |

|

4 |

149.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

174.8 |

R37 |

5.6 |

5.6 |

4.8 |

|

5 |

181.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

209.6 |

R41 |

5.6 |

5.6 |

4.8 |

|

6 |

211.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

241.3 |

R45 |

5.6 |

5.6 |

4.8 |

|

8 |

269.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

301.8 |

R49 |

5.6 |

5.6 |

4.8 |

|

10 |

323.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

355.6 |

R53 |

5.6 |

5.6 |

4.8 |

|

12 |

381.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

412.8 |

R57 |

5.6 |

5.6 |

4.8 |

|

14 |

419.1 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

457.2 |

R61 |

5.6 |

5.6 |

4.8 |

|

16 |

469.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

508.0 |

R65 |

5.6 |

5.6 |

4.8 |

|

18 |

533.4 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

574.8 |

R69 |

5.6 |

5.6 |

4.8 |

|

20 |

584.2 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

635.0 |

R73 |

5.6 |

5.6 |

4.8 |

|

24 |

692.2 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

749.3 |

R77 |

6.4 |

6.4 |

5.6 |

|

NPS |

Pitch Diameter of Ring and Groove |

Widthrong>of Ring |

Height Of Ring |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of RF for Ring Joint or Lapped |

Ring Number |

Appro. Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

3 |

123.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

155.4 |

R31 |

4.1 |

|

4 |

149.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

180.8 |

R37 |

4.1 |

|

5 |

181.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

215.9 |

R41 |

4.1 |

|

6 |

211.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

241.3 |

R45 |

4.1 |

|

8 |

269.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

307.8 |

R49 |

4.1 |

|

10 |

323.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

362.0 |

R53 |

4.1 |

|

12 |

381.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

419.1 |

R57 |

4.1 |

|

14 |

419.1 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

466.9 |

R62 |

4.1 |

|

16 |

469.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

523.7 |

R66 |

4.1 |

|

18 |

533.4 |

19.1 |

25.4 |

23.8 |

11.1 |

19.8 |

12.7 |

593.9 |

R70 |

4.8 |

|

20 |

584.2 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

647.7 |

R74 |

4.8 |

|

24 |

692.2 |

25.4 |

33.4 |

31.8 |

17.3 |

27.0 |

15.9 |

771.7 |

R78 |

5.6 |

|

NPS |

Pitch Diameter of Ring and Groove |

Widthrong>of Ring |

Height Of Ring |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of RF for Ring Joint or Lapped |

Ring No. |

Appr. Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

1/2 |

39.7 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

60.5 |

R12 |

4.1 |

|

3/4 |

44.5 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

66.8 |

R14 |

4.1 |

|

1 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

71.4 |

R16 |

4.1 |

|

1 1/4 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

81.0 |

R18 |

4.1 |

|

1 1/2 |

68.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

92.2 |

R20 |

4.1 |

|

2 |

95.3 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

124.0 |

R24 |

3.0 |

|

2 1/2 |

108.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

136.7 |

R27 |

3.0 |

|

3 |

136.5 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

168.4 |

R35 |

3.0 |

|

4 |

161.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

193.8 |

R39 |

3.0 |

|

5 |

193.7 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

228.6 |

R44 |

3.0 |

|

6 |

211.2 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

247.7 |

R46 |

3.0 |

|

8 |

269.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

317.5 |

R50 |

4.1 |

|

10 |

323.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

371.6 |

R54 |

4.1 |

|

12 |

381.0 |

22.2 |

28.6 |

27.0 |

14.8 |

23.0 |

14.3 |

438.2 |

R58 |

4.8 |

|

14 |

419.1 |

25.4 |

33.4 |

31.8 |

17.3 |

27.0 |

15.9 |

489.0 |

R64 |

5.6 |

|

16 |

469.9 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

546.1 |

R67 |

7.9 |

|

18 |

533.4 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

612.9 |

R71 |

7.9 |

|

20 |

584.2 |

31.8 |

39.7 |

38.1 |

22.3 |

33.4 |

17.5 |

673.1 |

R75 |

9.7 |

|

24 |

692.2 |

34.9 |

44.5 |

41.3 |

24.8 |

36.5 |

20.6 |

793.8 |

R79 |

11.2 |

|

NPS |

Pitch Diameter of Ring and Groove |

Widthrong>of Ring |

Height Of Ring |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of RFfor Ring Joint or Lapped |

Ring No. |

Approx. Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

1/2 |

42.9 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

65.0 |

R13 |

4.1 |

|

3/4 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

73.2 |

R16 |

4.1 |

|

1 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

82.6 |

R18 |

4.1 |

|

1 1/4 |

72.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

101.6 |

R21 |

3.0 |

|

1 1/2 |

82.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

114.3 |

R23 |

3.0 |

|

2 |

101.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

133.4 |

R26 |

3.0 |

|

2 1/2 |

111.1 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

149.4 |

R28 |

3.0 |

|

3 |

127.0 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

168.4 |

R32 |

3.0 |

|

4 |

157.2 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

203.2 |

R38 |

4.1 |

|

5 |

190.5 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

241.3 |

R42 |

4.1 |

|

6 |

228.6 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

279.4 |

R47 |

4.1 |

|

8 |

279.4 |

22.2 |

28.6 |

27.0 |

14.8 |

23.0 |

14.3 |

339.9 |

R51 |

4.8 |

|

10 |

342.9 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

425.5 |

R55 |

6.4 |

|

12 |

406.4 |

31.8 |

39.7 |

38.1 |

22.3 |

33.4 |

17.5 |

495.3 |

R60 |

7.9 |