-

-

send us mail

[email protected]

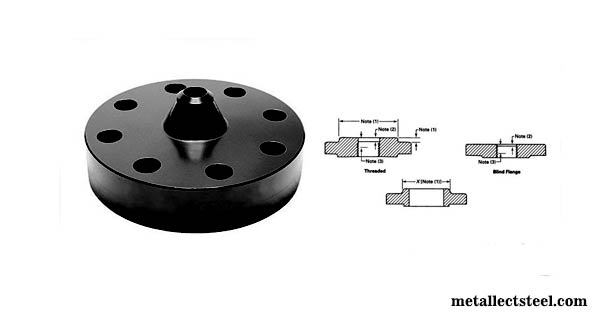

A reducing flange is a type of special flange, one which proves to be beneficial when used in projects that require the fitting together of two different sized pipes. There are many different types of reducing flanges some of which are as follows - weld neck reducing flange, slip-on ASME B16.5 Reducing Flange and threaded reducing flanges. Apart from ASME B16.5, manufacturers also use ASTM A182 specification in the construction of these flanges. The ASTM A182 SS Hubbed Reducing Flanges was designed with the intention of being used in high temperature environments. Which is why frequently these Alloy Steel Reducing Flange Materials are furnished by performing a heat treatment. After being hot worked, these forged flanges must be cooled to a specific temperature before its heat treatment. Generally, the heat treatment used on the ANSI B16.5 Carbon Steel Reducing Flange has to be performed in accordance with certain requirements, for instance, heat treatment type, austenitizing/solution temperature, cooling media, as well as quenching.

Get Reducing Flanges (RF), 4 Inch, 3/4 Normal Pipe Size, Class 150#, 300#, 600# SCH10 To SCH120 ASME B16.5 At Low Price.

The ASME B16.5 standard also includes certain recommendations in the form of pressure-temperature ratings, materials, Threaded Reducing Flange Dimensions, tolerances, marking, testing, and methods of designating openings, which are used by manufacturers during the production of pipe flanges and flanged fittings. In addition to conforming to the chemistry and mechanical properties of the ASTM A182 specification, the Stainless Steel Reducing Flange also includes requirements and recommendations of standard ASME B16.5 regarding flange bolting, flanges gaskets, and flanges joints.

| Specification : | ASME B16.5 Reducing Flange |

| Design For Size: | ASA, ASME, DIN, PN, JIS, ANSI, BS, EN |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Connect Type Type: | RF, FF, RTJ, LMF, SMF, LJF. |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Production Process: | Forged, Heat Treated and Machined |

| Standards : | ASME B16.5, ASME B16.47 (Series A, Series B), ASME B16.38, EN-1092, BS10, DIN, PN, JIS, ISO, GOST, UNI, AWWA, MSS SP44. |

| Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine, Press machine, electric bevelling machine etc |

| Coating Flanges Faces : | Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated |

| ASME B16.5 Application: | Oil And Gas Industry Nuclear Power Plant Natural Gas Industry Chemical Industry Fabrication Industry Water Pipeline Industry |

|

Normal Pipe Size |

Diam. |

Thick. |

DIA. |

Welding |

Minimum. |

Minimum. |

Minimum. |

Neck |

Welding |

Joint |

||||

|

DN |

O |

T |

A |

B |

C |

D |

E |

F |

G |

H |

||||

|

1/2 |

5.25 |

1.19 |

1.38 |

0.88 |

.90 |

0.93 |

2.88 |

1.56 |

1.56 |

|||||

|

15 |

133 |

30.5 |

34.9 |

22.2 |

22.9 |

23.5 |

73.0 |

40 |

40 |

|||||

|

3/4 |

5.50 |

1.25 |

1.69 |

1.09 |

1.11 |

1.14 |

3.12 |

1.69 |

1.69 |

|||||

|

20 |

140 |

32.0 |

42.9 |

27.8 |

28.2 |

29.0 |

79.4 |

43 |

43 |

|||||

|

1 |

6.25 |

1.38 |

2.00 |

1.36 |

1.38 |

1.41 |

3.50 |

1.88 |

1.88 |

|||||

|

25 |

159 |

35.0 |

50.8 |

34.5 |

34.9 |

36.0 |

88.9 |

48 |

48 |

|||||

|

1 1/4 |

7.25 |

1.50 |

2.50 |

1.70 |

1.72 |

1.75 |

3.75 |

2.06 |

2.06 |

|||||

|

32 |

184 |

38.5 |

63.5 |

43.3 |

43.7 |

44.5 |

95.2 |

52 |

52 |

|||||

|

1 1/2 |

8.00 |

1.75 |

2.88 |

1.95 |

1.97 |

1.99 |

4.38 |

2.38 |

2.38 |

|||||

|

40 |

203 |

44.5 |

73.0 |

49.6 |

50.0 |

50.5 |

111.4 |

60 |

60 |

|||||

|

2 |

9.25 |

2.00 |

3.62 |

To be |

2.44 |

2.46 |

2.50 |

5.00 |

2.75 |

2.75 |

||||

|

50 |

235 |

51.0 |

92.1 |

61.9 |

62.5 |

63.5 |

127.0 |

70 |

70 |

|||||

|

2 1/2 |

10.50 |

2.25 |

4.12 |

specified |

2.94 |

2.97 |

3.00 |

5.62 |

3.12 |

3.12 |

||||

|

65 |

267 |

57.5 |

104.8 |

74.6 |

75.4 |

76 |

142.9 |

79 |

79 |

|||||

|

3 |

12.00 |

2.62 |

5.00 |

by |

3.57 |

3.60 |

3.63 |

6.62 |

3.62 |

3.62 |

||||

|

80 |

305 |

67.0 |

127.0 |

90.7 |

91.4 |

92 |

168.2 |

92 |

92 |

|||||

|

4 |

14.00 |

3.00 |

6.19 |

purchaser |

4.57 |

4.60 |

4.63 |

7.50 |

4.25 |

4.25 |

||||

|

100 |

356 |

76.5 |

157.2 |

116.1 |

116.8 |

118 |

190.5 |

108 |

108 |

|||||

|

5 |

16.50 |

3.62 |

7.31 |

5.66 |

5.69 |

5.69 |

9.00 |

5.12 |

5.12 |

|||||

|

125 |

419 |

92.5 |

185.7 |

143.7 |

144.5 |

145 |

228.6 |

130 |

130 |

|||||

|

6 |

19.00 |

4.25 |

8.50 |

6.72 |

6.75 |

6.75 |

10.75 |

6.0 |

6.0 |

|||||

|

150 |

483 |

108.0 |

215.9 |

170.7 |

171.4 |

171 |

273.0 |

152 |

152 |

|||||

|

8 |

21.75 |

5.00 |

10.62 |

8.72 |

8.75 |

8.75 |

12.50 |

7.0 |

7.0 |

|||||

|

200 |

552 |

127.0 |

269.9 |

221.5 |

222.2 |

222 |

317.5 |

178 |

178 |

|||||

|

10 |

26.50 |

6.50 |

12.75 |

10.88 |

10.92 |

10.88 |

16.50 |

9.0 |

9.0 |

|||||

|

250 |

675 |

165.5 |

323.8 |

276.2 |

277.4 |

276 |

419.4 |

229 |

229 |

|||||

|

12 |

30.00 |

7.25 |

15.00 |

12.88 |

12.92 |

12.94 |

18.25 |

10.0 |

10.0 |

|||||

|

300 |

760 |

184.5 |

381.0 |

327.0 |

328.2 |

329 |

463.6 |

254 |

254 |

|||||

Dimensions do not include .25" (6.4 mm) FF.

2500# (PN 420) Socket Welding and SORF Flanges not covered by ASME B16.5

4 X 3 Reducing Weld Neck Flange

EN 1092-2 PN16 Reducing Slip On Flange

4 x 2-1/2 inch 300# Threaded Reducings Flange

SCH40 10 x 3 inch Reducings Flange Adapter

ASTM A182 Class 600 Stainless Steel Reducings Flange

6 inch A105 Carbon Steel Reducings Flange

1/2 To 3/4 SCH 10 150# Ductile Iron Reducing Flange

EN 1092-1 Type 02 Cast Iron Reducings Flange

3 x 2 inch Pipe Reducings Hub Flange

F304 300# Welding Reducings Companion Flange

ANSI 4 Inch 150 Lb Reducings Flange

Concentirc Galvanized Reducings Flange

| NPS | Type | Ø A | D | Liner Thick. |

|

| DN1 | DN2 | ||||

| Inch | Inch | millimeter | millimeter | millimeter | |

| 3/4" | 1/2" | 1 | 98.5 | 30 | 5.0 |

| 1" | 1/2" | 1 | 108 | 30 | 5.0 |

| 1" | 3/4" | 1 | 108 | 30 | 5.0 |

| 1.1/2" | 1/2" | 1 | 127 | 30 | 5.0 |

| 1.1/2" | 3/4" | 1 | 127 | 30 | 5.0 |

| 1.1/2" | 1" | 1 | 127 | 30 | 5.0 |

| 2" | 1/2" | 3 | 152 | 30 | 5.0 |

| 2" | 3/4" | 2 | 152 | 30 | 5.0 |

| 2" | 1" | 2 | 152 | 30 | 5.0 |

| 2" | 1.1/2" | 1 | 152 | 30 | 5.0 |

| 3" | 3/4" | 3 | 190.5 | 35 | 5.0 |

| 3" | 1" | 3 | 190.5 | 35 | 5.0 |

| 3" | 1.1/2" | 2 | 190.5 | 35 | 5.0 |

| 3" | 2" | 1 | 190.5 | 35 | 5.0 |

| 4" | 3/4" | 3 | 228.6 | 35 | 5.0 |

| 4" | 1" | 3 | 228.6 | 35 | 5.0 |

| 4" | 1.1/2" | 3 | 228.6 | 35 | 5.0 |

| 4" | 2" | 3 | 228.6 | 35 | 5.0 |

| 4" | 3" | 2 | 228.6 | 35 | 5.0 |

| 6" | 3/4" | 3 | 280 | 40 | 5.0 |

| 6" | 1" | 3 | 280 | 40 | 5.0 |

| 6" | 1.1/2" | 3 | 280 | 40 | 5.0 |

| 6" | 2" | 3 | 280 | 40 | 5.0 |

| 6" | 3" | 3 | 280 | 40 | 5.0 |

| 6" | 4" | 2 | 280 | 40 | 5.0 |

| 8" | 1" | 3 | 343 | 35 | 5.0 |

| 8" | 1.1/2" | 3 | 343 | 35 | 5.0 |

| 8" | 2" | 3 | 343 | 40 | 5.0 |

| 8" | 3" | 3 | 343 | 40 | 5.0 |

| 8" | 4" | 3 | 343 | 40 | 5.0 |

| 8" | 6" | 2 | 343 | 40 | 5.0 |

| 10" | 1" | 3 | 406 | 35 | 2.5 |

| 10" | 1.1/2" | 3 | 406 | 35 | 2.5 |

| 10" | 2" | 3 | 406 | 35 | 2.5 |

| 10" | 3" | 3 | 406 | 35 | 2.5 |

| 10" | 4" | 3 | 406 | 35 | 2.5 |

| 10" | 6" | 3 | 406 | 35 | 2.5 |

| 10" | 8" | 2 | 406 | 35 | 3.5 |

| 12" | 1" | 3 | 483 | 35 | 3.5 |

| 12" | 1.1/2" | 3 | 483 | 35 | 3.5 |

| 12" | 2" | 3 | 483 | 35 | 3.5 |

| 12" | 3" | 3 | 483 | 35 | 3.5 |

| 12" | 4" | 3 | 483 | 35 | 3.5 |

| 12" | 6" | 3 | 483 | 35 | 3.5 |

| 12" | 8" | 3 | 483 | 35 | 3.5 |

| 12" | 10" | 2 | 483 | 35 | 3.5 |

| 14" | 12" | 1 | 533 | 40 | 3.5 |

| 16" | 12" | 3 | 597 | 40 | 3.5 |

| 16" | 14" | 2 | 597 | 35 | 3.5 |

| ASNME B16.5 Reducings Flange Pressure Rating |

|||||||

| Temperature (F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |