-

-

send us mail

[email protected]

Applications that require the use of flat face flanges are frequently those systems where the mating flanges or flanged fitting is produced from a casting. The ANSI B16.5 standard is limited to those flanges and their corresponding fittings which are generally made from cast or forged materials. An ASME B16.5 Flat Face Flange has a gasket surface in the same plane as the bolting circle face. The ANSI B16.5 Flat Face Flange Standards also includes requirements as well as recommendations regarding flanges gaskets, flanges bolting, and flanges joints. Essential points covered by the standard include pressure-temperature ratings, tolerances, marking, materials, dimensions, testing, and the various methods of designating openings for Carbon Steel Flat Face Flange and flanged fittings. While the pressure rating of these flanges is in the following class designations i.e. 150, 300, 400, 600, 900, 1500, and 2500, a Stainless Steel Flat Flange is produced by manufacturers in sizes NPS 1/2 through NPS 24.

Compare prices before you buy Flat Face (FF), DIN 2576, 2 x 4 Inch 150#, Forged Schedule 40, ASTM A182, ASME B16.5 In India.

It is important to note that a flat face flange is never to be bolted to a raised face flanges. ASME B31.1 says that when connecting a cast iron Flat Face Slip On Flange to carbon steel flanges, the raised face on the carbon steel flanges must be removed, which is why a full face gasket is required. This is to keep the thin, brittle cast iron ANSI B16.5 Flange Flat Dimensions from being sprung into the gap that has been caused by the raised face of the carbon steel flanges used as a mating.

| Specification : | ASME B16.5 Flat Face Flange |

| Design For Size: | ASA, ASME, DIN, PN, JIS, ANSI, BS, EN |

| ASME B16.5 Application: | Nuclear Power Plant Natural Gas Industry Chemical Industry Water Pipeline Industry Fabrication Industry Oil And Gas Industry |

| Connect Type Type: | RF, FF, RTJ, LMF, SMF, LJF. |

| ASA Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Standards : | ASME B16.5, ASME B16.38, EN-1092, BS10, DIN, PN, JIS, ASME B16.47 (Series A, Series B), ISO, GOST, UNI, AWWA, MSS SP44. |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Machining Equipment: | Bending machine, Sand-blasting machine, Press machine, Pushing Machine, electric bevelling machine etc |

| Production Process: | Forged, Heat Treated and Machined |

| Coating Flanges Faces : | Yellow Transparent, Anti-rust Paint, Cold and Hot Dip Galvanized, Oil Black Paint, Zinc Plated |

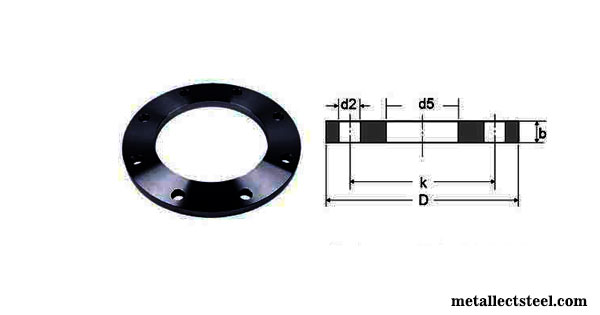

| NPS | Diameter of Pipe | Flange I.Diameter | NUmber of holes | Flange Diameter | Thickness of Flange | Diameter of Bolt Circle | Diameter of Bolt Holes | Approx. Weight | |

| DN | ISO | DIN | D5 | BN | D | b | K | d2 | KG/PCS |

| 10 | – | 14 | 14.5 | 4 | 90 | 16 | 60 | 14 | 0.7 |

| 17.2 | – | 17.7 | 4 | 90 | 16 | 60 | 14 | 0.69 | |

| 15 | – | 20 | 21 | 4 | 95 | 16 | 65 | 14 | 0.77 |

| 21.3 | – | 22 | 4 | 95 | 16 | 65 | 14 | 0.77 | |

| 20 | – | 25 | 26 | 4 | 105 | 18 | 75 | 14 | 1.06 |

| 26.9 | – | 27.6 | 4 | 105 | 18 | 75 | 14 | 1.05 | |

| 25 | – | 30 | 31 | 4 | 115 | 18 | 85 | 14 | 1.27 |

| 33.7 | – | 34.4 | 4 | 115 | 18 | 85 | 14 | 1.25 | |

| 32 | – | 38 | 39 | 4 | 140 | 18 | 100 | 18 | 1.86 |

| 42.4 | – | 43.1 | 4 | 140 | 18 | 100 | 18 | 1.83 | |

| 40 | – | 44.5 | 45.5 | 4 | 150 | 18 | 110 | 18 | 2.12 |

| 48.3 | – | 49 | 4 | 150 | 18 | 110 | 18 | 2.09 | |

| 50 | – | 57 | 58.1 | 4 | 165 | 20 | 125 | 18 | 2.78 |

| 60.3 | – | 61.1 | 4 | 165 | 20 | 125 | 18 | 2.74 | |

| 65 | 76.1 | – | 77.1 | 8 | 185 | 22 | 145 | 18 | 3.48 |

| 80 | 88.9 | – | 90.3 | 8 | 200 | 24 | 160 | 18 | 4.33 |

| 100 | – | 108 | 109.6 | 8 | 235 | 24 | 190 | 22 | 5.82 |

| 114.3 | – | 115.9 | 8 | 235 | 24 | 190 | 22 | 5.61 | |

| 125 | – | 133 | 134.8 | 8 | 270 | 26 | 220 | 26 | 7.91 |

| 139.7 | – | 141.6 | 8 | 270 | 26 | 220 | 26 | 7.6 | |

| 150 | – | 159 | 161.1 | 8 | 300 | 28 | 250 | 26 | 10.12 |

| 168.3 | – | 170.5 | 8 | 300 | 28 | 250 | 26 | 9.58 | |

| 175 | 193.7 | – | 196.1 | 12 | 350 | 32 | 295 | 30 | 14.45 |

| 200 | 219.1 | – | 221.8 | 12 | 375 | 34 | 320 | 30 | 16.9 |

| 250 | – | 267 | 270.2 | 12 | 450 | 38 | 385 | 33 | 27.28 |

| 273 | – | 276.2 | 12 | 450 | 38 | 385 | 33 | 26.51 | |

| 300 | 323.9 | – | 327.6 | 16 | 515 | 42 | 450 | 33 | 36.38 |

| 350 | 355.6 | – | 359.7 | 16 | 580 | 46 | 510 | 36 | 52.83 |

| – | 368 | 372.2 | 16 | 580 | 46 | 510 | 36 | 50.24 | |

| 400 | 406.4 | – | 411 | 16 | 660 | 50 | 585 | 39 | 74.71 |

| – | 419 | 423.7 | 16 | 660 | 50 | 585 | 39 | 71.44 | |

| 500 | 508 | – | 513.6 | 20 | 755 | 52 | 670 | 42 | 86.87 |

| 600 | 610 | – | 616.5 | 20 | 890 | 54 | 795 | 48 | 121.84 |

| 700 | 711 | – | 716 | 24 | 995 | 58 | 900 | 48 | 150.93 |

| 800 | 813 | – | 818 | 24 | 1140 | 64 | 1030 | 56 | 219.08 |

| 900 | 914 | – | 920 | 28 | 1250 | 70 | 1140 | 56 | 271.16 |

| 1000 | 1016 | – | 1022 | 28 | 1360 | 78 | 1250 | 56 | 344.95 |

Gost Cs Ct20 Forged Flat Flange Din 2576

ASTM A182 SS 400 Weld Neck Flat Face Flange

A182 Stainless Steel Flat Face Socket Weld Flange

12 Inch ANSI Standard Ring Type Gasket For Flat Face Flange

High Quality GOST Standard 12820 Threaded Flat Face Flange

Class 1500 Raised Face To Flat Face Flanges Adapter

AS 4087 F316 DN65 Raised Face To Flat Face Flanges Spacer

ASTM A182 F316L 150# Flat Face Slip On Flange

ANSI B16.5 Class 150 LB PN10 Flat Face Plate Flange

Weld Neck Flange FF Stainless Steel Flat Face Flange

ASME B16.5 Forged Steel Class 300 Hydraulic Flat Face Flange

EN1092-1 TYPE 01 304 600 Lb Flat Face Flange

| Dimensions | Base Material |

|---|---|

| ASME B16.47series A & B | ASTM A240 (Plate), ASTM A182 (Forgings) |

| API 605 | ASTM A240 (Plate), ASTM A182 (Forgings) |

| ASME B16.5 | ASTM A240 (Plate), ASTM A182 (Forgings) |

| BS4504 | ASTM A182 (Forgings), BS970 (Bar)ASTM A240 (Plate), |

| BS10 | ASTM A182 (Forgings), BS970 (Bar)ASTM A240 (Plate) |

| EN1092-1 | ASTM A182 (Forgings) |