-

-

send us mail

[email protected]

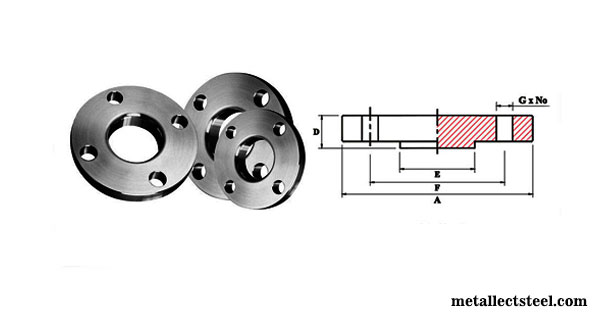

Frequently this type of flange has been referred to as a raised face due to the gasket surfaces, which is raised above the bolting circle face. This face type in an ASME B16.5 Raised Face Flange is what permits the use of a wide combination of gasket designs, including a flat ring sheet type as well as metallic composites, for instance, spiral wound and double jacketed types. One of the most easily to identified components, the Carbon Steel Raised Face Flanges Weight Chart has been commonly used in process plant based applications.

Buy RF Flange, 1-1/4 inch, 150# 316L, SW, ASME B16.5, SCH 10 To SCH 80, ASTM A105.

The purpose of a 6 inch Slip On Raised Face Flange is to concentrate more pressure on a smaller gasket area. This in turn, effectively increases the pressure containment capacity of the joint. The Stainless Steel Rf Flange Dimensions such as the diameter and height are mentioned in standard ASME B16.5 defined, by pressure class and diameter. The pressure rating of a raised flanges will determine the height of the raised face. The ASME B16.5 standard includes Raised Face Cast Iron Flanges with the following rating class designations i.e. class 150, 300, 400, 600, 900, 1500, and 2500 produced in a size range between NPS 1/2 through NPS 24, with their requirements given in both metric and U.S units. In addition to the pressure rating and the dimensions, the ASME B16.5 standard covers ANSI B16.5 Rf Flange Material, tolerances, marking, testing, as well as methods of designating openings for flanges and flanged fittings to be used in a piping system.

| Specification : | ASME B16.5 Raised Face Flange |

| Production Process: | Forged, Heat Treated and Machined |

| ASME B16.5 Application: | Water Pipeline Industry Chemical Industry Fabrication Industry Oil And Gas Industry Natural Gas Industry Nuclear Power Plant |

| Design For Size: | ASA, ASME, ANSI, BS, EN, DIN, PN, JIS |

| ASA Flanges Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Standards : | ASME B16.5, JIS, ISO, ASME B16.38, EN-1092, BS10, DIN, GOST, UNI, ASME B16.47 (Series A, Series B), PN, AWWA, MSS SP44. |

| Connect Type Type: | RF, LMF, SMF, FF, RTJ, LJF. |

| Machining Equipment: | Bending machine, Press machine, electric bevelling machine, Pushing Machine, Sand-blasting machine etc |

| Coating Faces : | Yellow Transparent, Cold and Hot Dip Galvanized, Zinc Plated, Oil Black Paint, Anti-rust Paint |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

3/4 Blind Flange 150# Raised Face Flange

Din pn10 Slip On Raised Face Flange

JIS 304 Stainless Steel Raised Face Weld Neck Flange

ASTM A105n B16.5 Carbon Steel Raised Face Blind Flange

6 Inch 300 Lb Raised Face Blind Flange

DIN2631 / DIN2632Raised Face Socket Weld Flange

ASTM A182 F316 Large Raised Face Cast Iron Flange

ANSI B16.5 2 inch Std A105 Carbon Steel Raised Face Flange

ISO7005 DIN2543 Stainless Steel Raised Face Flange

ANSI B16.5 150# SORF Aluminum Raised Face Flange

GOST 12821-80 CT20 Class 300 Raised Face Flange

Rf Flanges 150# Dimensions Table D

ANSI |

OD | OD | THICK. | DIAM. | DIAM. | NO. | DIAM. | |

|---|---|---|---|---|---|---|---|---|

| DIAM. | DIAM. OF | OF FLANGE | OF BOLT | OF BOLT | ||||

| CLASS | NPS | OF BOLTS | OF BOLTS | |||||

| OF FLANGE | RAISED FACE | tf | CIRCLE | HOLES | ||||

| 3/4 | 3.88 | 1.69 | 0.44 | 2.75 | 0.62 | 4 | 0.50 | |

| 1 | 4.25 | 2.00 | 0.50 | 3.12 | 0.62 | 4 | 0.50 | |

| 1 1/2 | 5.00 | 2.88 | 0.62 | 3.88 | 0.62 | 4 | 0.50 | |

| 2 | 6.00 | 3.62 | 0.69 | 4.75 | 0.75 | 4 | 0.62 | |

| 3 | 7.50 | 5.00 | 0.88 | 6.00 | 0.75 | 4 | 0.62 | |

| 4 | 9.99 | 6.19 | 0.88 | 7.50 | 0.75 | 8 | 0.62 | |

| 150 | 6 | 11.00 | 8.50 | 0.94 | 9.50 | 0.88 | 8 | 0.75 |

| 8 | 13.50 | 10.62 | 1.06 | 11.75 | 0.88 | 8 | 0.75 | |

| 10 | 16.00 | 12.75 | 1.12 | 14.25 | 1.00 | 12 | 0.87 | |

| 12 | 19.00 | 15.00 | 1.19 | 17.00 | 1.00 | 12 | 0.87 | |

| 14 | 21.00 | 16.25 | 1.31 | 18.75 | 1.12 | 12 | 1.00 | |

| 16 | 23.50 | 18.50 | 1.38 | 21.25 | 1.12 | 16 | 1.00 | |

| 18 | 25.00 | 21.00 | 1.50 | 22.75 | 1.25 | 16 | 1.12 | |

| 20 | 27.50 | 23.99 | 1.62 | 25.00 | 1.25 | 20 | 1.12 | |

| 24 | 32.00 | 27.25 | 1.82 | 29.50 | 1.38 | 20 | 1.25 | |

| 3/4 | 4.62 | 1.69 | 0.56 | 3.25 | 0.75 | 4 | 0.62 | |

| 1 | 4.88 | 2.00 | 0.62 | 3.50 | 0.75 | 4 | 0.62 | |

| 1 1/2 | 6.12 | 2.88 | 0.75 | 4.25 | 0.88 | 4 | 0.75 | |

| 2 | 6.50 | 3.62 | 0.81 | 5.00 | 0.75 | 8 | 0.62 | |

| 3 | 8.25 | 5.00 | 1.06 | 6.62 | 0.88 | 8 | 0.75 | |

| 4 | 10.00 | 6.19 | 1.19 | 7.88 | 0.88 | 8 | 0.75 | |

| 300 | 6 | 12.50 | 8.50 | 1.38 | 10.62 | 0.88 | 12 | 0.75 |

| 8 | 15.00 | 10.62 | 1.56 | 13.00 | 1.00 | 12 | 0.87 | |

| 10 | 17.50 | 12.75 | 1.82 | 15.25 | 1.12 | 16 | 1.00 | |

| 12 | 20.50 | 15.00 | 1.94 | 17.75 | 1.25 | 16 | 1.12 | |

| 14 | 23.00 | 16.25 | 2.06 | 20.25 | 1.25 | 20 | 1.12 | |

| 16 | 25.50 | 18.50 | 2.19 | 22.50 | 1.38 | 20 | 1.25 | |

| 18 | 28.00 | 21.00 | 2.31 | 24.75 | 1.38 | 24 | 1.25 | |

| 20 | 30.50 | 23.00 | 2.44 | 27.00 | 1.38 | 24 | 1.25 | |

| 1 | 4.88 | 2.00 | 0.69 | 3.50 | 0.75 | 4 | 0.62 | |

| 1 1/2 | 6.12 | 2.88 | 0.88 | 4.50 | 0.88 | 4 | 0.75 | |

| 2 | 6.50 | 3.62 | 1.00 | 5.00 | 0.75 | 8 | 0.62 | |

| 3 | 8.25 | 5.00 | 1.25 | 6.62 | 0.88 | 8 | 0.75 | |

| 4 | 10.75 | 6.19 | 1.50 | 8.50 | 1.00 | 8 | 0.87 | |

| 600 | 6 | 14.00 | 8.50 | 1.88 | 11.50 | 1.12 | 12 | 1.00 |

| 8 | 16.50 | 10.62 | 2.19 | 13.75 | 1.25 | 12 | 1.12 | |

| 10 | 20.00 | 12.75 | 2.50 | 17.00 | 1.38 | 16 | 1.25 | |

| 12 | 22.00 | 15.00 | 2.62 | 19.25 | 1.38 | 20 | 1.25 | |

| 14 | 23.75 | 16.25 | 2.75 | 20.75 | 1.50 | 20 | 1.37 | |

| 16 | 27.00 | 18.50 | 3.00 | 23.75 | 1.62 | 20 | 1.50 | |

| 1 1/2 | 7.00 | 2.88 | 1.25 | 4.88 | 1.12 | 4 | 1.00 | |

| 2 | 8.50 | 3.62 | 1.50 | 6.50 | 1.00 | 8 | 0.87 | |

| 3 | 9.50 | 5.00 | 1.50 | 7.50 | 1.00 | 8 | 0.87 | |

| 900 | 4 | 11.50 | 6.19 | 1.75 | 9.25 | 1.25 | 8 | 1.12 |

| 6 | 15.00 | 8.50 | 2.19 | 12.50 | 1.25 | 12 | 1.12 | |

| 8 | 18.50 | 10.62 | 2.50 | 15.50 | 1.50 | 12 | 1.37 | |

| 10 | 21.50 | 12.75 | 2.75 | 18.50 | 1.50 | 16 | 1.37 | |

| 1 1/2 | 7.00 | 2.88 | 1.25 | 4.88 | 1.12 | 4 | 1.00 | |

| 2 | 8.50 | 3.62 | 1.50 | 6.50 | 1.00 | 8 | 0.87 | |

| 1500 | 3 | 10.50 | 5.00 | 1.88 | 8.00 | 1.25 | 8 | 1.12 |

| 4 | 12.25 | 6.19 | 2.12 | 9.50 | 1.38 | 8 | 1.25 | |

| 6 | 15.50 | 8.50 | 3.25 | 12.50 | 1.50 | 12 | 1.37 | |

| 8 | 19.00 | 10.62 | 3.62 | 15.50 | 1.75 | 12 | 1.62 |

| ASME B16.5 Raised Face Flanges Pressure Ratings |

|||||||

| Temperature (F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |