-

-

send us mail

[email protected]

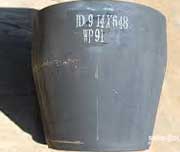

To illustrate, the letter W in the term WP indicates weldable, while the letter P stands for Pressure and the number 91 is its grade. Often industries such as Oil, Gas, Water Treatment, Chemical as well as the Power plants use the ASTM A234 WP91 Fittings in their day to day applications. Since the alloying content in the ASTM A234 specified fittings is low its hardness is a property that is higher. Hence, the A234 WP91 Welded Fittings tend to exhibit better performance for those applications that require abrasive resistance and moderate to very low corrosion resistance properties. A buttweld fitting, for e.g. ASTM A234 is a specification that covers seamless as well as welded fittings constructed the different grades of carbon steel and alloy steel. One such grade is the WP91 fitting.

ASME B16.11 SA234 WP91 Tee is a weldable pipe fitting that permits for diversification of direction of flow of media, which is its primary function.

The secondary functions of the ASTM A234 WP91 Pipe Fittings include to branch off, reduce the size of a pipe or to attach auxiliary equipment. Buttweld fittings are available in various forms like elbows, tees, caps, reduces and outlets or what is also referred to as an olet. These fittings are specified by nominal pipe size along with the pipe schedule. Fittings of Buttweld SA234 WP91 Material are also known as Welded Pipe fittings. These welded fittings in carbon steel and alloy steel offer many advantages as compared to either threaded or socket weld fittings. The other important characteristics of Alloy Steel A234 Gr WP91 Elbow include durability, high strength, stability and good dimensional accuracy.

ASTM A234 Grade WP91 Reducing Tee

ASTM A234 WP91 Lateral Tee

Alloy Steel ASTM A234 WP91 Cl1 Equal Cross

A234 WP91 Welded Stub End

SA234 Gr WP91 Concentric Reducer

ASTM A234 Grade WP91 Equal Tee

Alloy Steel Grade WP91 45 Degree Elbow

A234 Grade Alloy 90 Degree Elbow

A234 Grade WP91 End Cap

Alloy Steel Grade WP91 Short Radius Elbow

AS a234 WP91 LR Elbow

Alloy Steel WP91 Eccentric Reducer

| Standard Specification : | ASTM A234 WP91 Fittings |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Fitting Machining Equipment: | Pushing Machine, electric bevelling machine, Sand-blasting machine, Press machine, Bending machine etc |

| Coating Fitting Faces : | Yellow Transparent, Oil Black Paint, Zinc Plated, Anti-rust Paint, Cold and Hot Dip Galvanized |

| Standard: | ANSI B16.28 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, MSS-SP-43 Type b Fittings, MSS-SP-43 Type B Fittings, JIS B2312 Fittings |

| Application: | Natural Gas Industry Oil And Gas Industry Water Pipeline Industry Nuclear Power Plant Fabrication Industry Chemical Industry |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

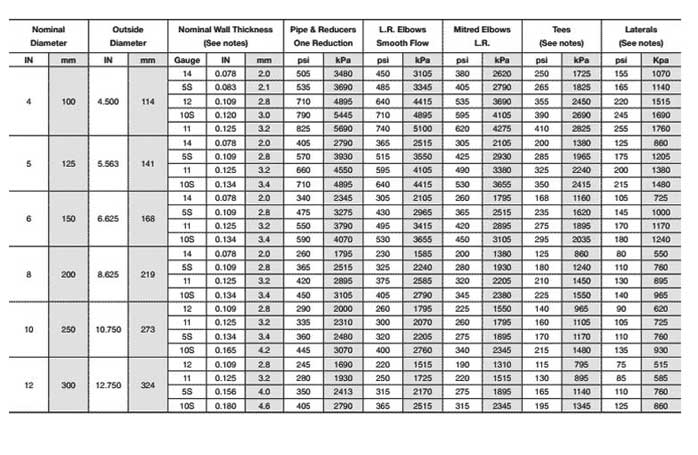

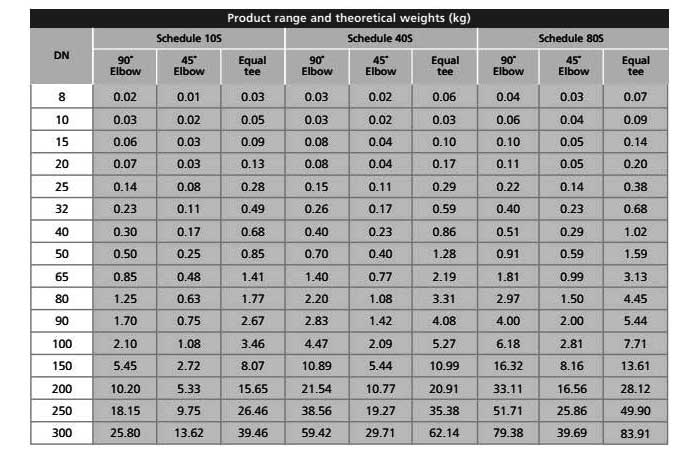

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

WPB B,C,D,E, |

WPC C,D,E, | WP11 CL1 | WP11 CL2, | WP11 CL3 | WP22 CL1, | WP22 CL3 | WP5 CL1, | WP5 CL3 |

|---|---|---|---|---|---|---|---|---|

| Carbon | 0.3 | 0.35 | 0.05–0.15 | 0.05–0.20 | 0.05–0.20 | 0.05–0.15 | 0.05–0.15 | 0.15 |

| Manganese | 0.29–1.06 | 0.29–1.06 | 0.30–0.60 | 0.30–0.80 | 0.30–0.80 | 0.30–0.60 | 0.30–0.60 | 0.30–0.60 |

| Phosporus | 0.05 | 0.05 | 0.03 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Sulfur | 0.058 | 0.058 | 0.03 | 0.04 | 0.04 | 0.04 | 0.04 | 0.03 |

| Silicon | 0.10 min | 0.10 min | 0.50–1.00 | 0.50–1.00 | 0.50–1.00 | 0.5 | 0.5 | 0.5 |

| Chromium | 0.4 | 0.4 | 1.00–1.50 | 1.00–1.50 | 1.00–1.50 | 1.90–2.60 | 1.90–2.60 | 4.0–6.0 |

| Molybdenum | 0.15 max | 0.15 max | 0.44–0.65 | 0.44–0.65 | 0.44–0.65 | 0.87–1.13 | 0.87–1.13 | 0.44–0.65 |

| Nickel | 0.4 | 0.4 | … | … | … | … | … | … |

| Copper | 0.4 | 0.4 | … | … | … | … | … | … |

| Others | Vanadium 0.08 | Vanadium 0.08 | … | … | … | … | … | … |

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| ASTM A234 WP91 Fittings | 415 - 585 | ≥205 | ≥20 |