-

-

send us mail

[email protected]

Produced in a seamless or welded construction, the ASTM A234 specification could be used for applications involving pressure piping systems as well as pressure vessel fabrication, especially in environments where the temperature settings could be either ambient or elevated. The heat treatments performed on the ASTM A234 fittings include full annealing, isothermal annealing, or normalizing and tempering. These ASTM A234 WP22 Fittings are to be furnished by tempering at a temperature that is not less than 1250°F. Usually, fittings belonging to class 1, 2 and 3 are first liquid quenching followed by the performance of a tempering process. The tempering process can be permitted for all Forged A234-WP22 Cl3 Fitting only when it has been approved by the purchaser. The specification makes a detail mention in terms of the forming process for these fittings.

The different parameters to be taken into account while forming the AS A234 WP22 Elbow is the type of forging process used, heat treatment and the rate of cooling.

With the exception for dimensional inspection and for visual examination, the inspection & tests that are to be selectively performed on Alloy Steel A234 WP22 CL1 Pipe Fitting. These tests include a liquid penetration test, hydrostatic test, ultrasonic test, magnetic particle examination, non-destructive electromagnetic test or what is also referred to as an eddy current test. The Buttweld A234 WP22 Material has good dimensional stability, high toughness and hardness properties while exhibiting superior strength. A combination of these properties, coupled with the fact that they tend to be relatively less expensive in comparison makes the ASME B16.11 A234 WP22 Cl2 Cap an attractive fitting to be used across different industrial sectors.

| Standard Specification : | ASTM A234 WP22 Fittings |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

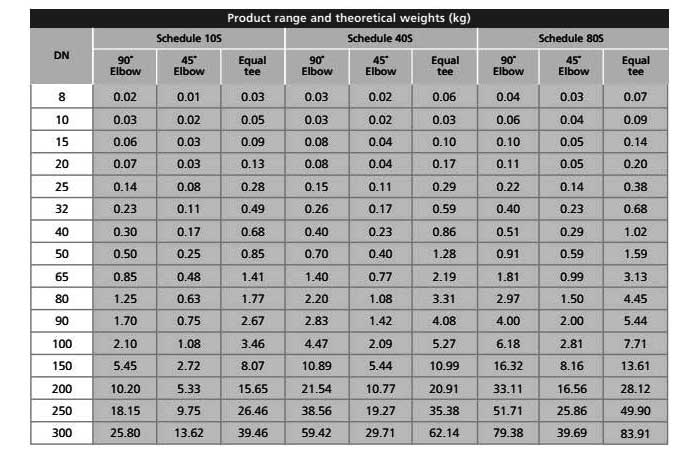

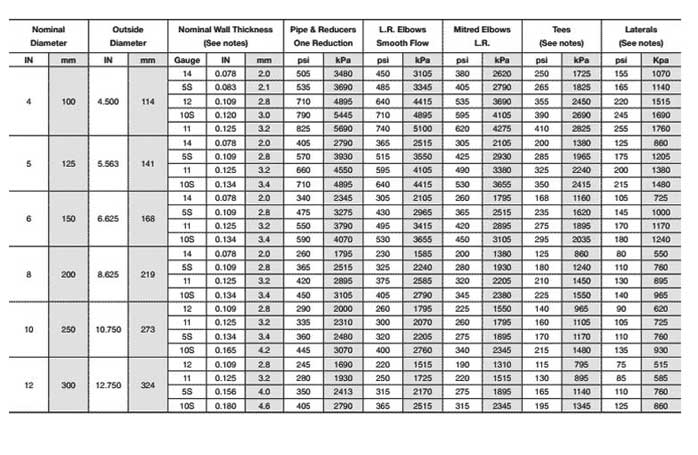

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | MSS-SP-43 Type b Fittings, MSS-SP-43 Type B Fittings, ANSI B16.28 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, JIS B2312 Fittings |

| Fitting Machining Equipment: | Sand-blasting machine, Press machine, Pushing Machine, electric bevelling machine, Bending machine etc |

| Coating Fitting Faces : | Anti-rust Paint, Cold and Hot Dip Galvanized, Yellow Transparent, Oil Black Paint, Zinc Plated |

| Application: | Nuclear Power Plant Oil And Gas Industry Water Pipeline Industry Natural Gas Industry Fabrication Industry Chemical Industry |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Grade | C | Mn | Si | S | P | Cr | Mo |

| ASTM A234 WP22 Fittings | 0.05-0.15 | 0.3-0.5 | 0.5 | ≤0.04 | ≤0.04 | 2-2.5 | 0.87-1.13 |

SA234 Gr WP22 Concentric Reducer

ASTM A234 Grade WP22 Equal Tee

Alloy Steel Grade WP22 45 Degree Elbow

Alloy Steel A234 Grade 90 Degree Elbow

A234 Grade WP22 End Cap

Alloy Steel Grade WP22 Short Radius Elbow

AS a234 WP22 LR Elbow

Alloy Steel WP22 Eccentric Reducer

ASTM A234 Grade WP22 Reducing Tee

ASTM A234 WP22 Lateral Tee

ASTM A234 WP22 Cl1 Equal Cross

A234 WP22 Alloy Welded Stub End

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| SA 234 WP22 | 415 - 585 | ≥205 | ≥20 |