-

-

send us mail

[email protected]

Various industries such as the oil and gas industry, Petrochemical Industry, Chemical Industry, Manufacture of Valves & Pumps, Marine Industry, as well as the paper and pulp industry require fittings in forms like Elbows, Crosses, Tees, Reducers, Stub End, Pipe Cap and Pipe Bend that has a tolerance for high temperature applications. Since the ASTM A234 WP11 Fittings can withstand elevated temperatures, they have the ability to retain their shape even under high pressure conditions. With an increase in heat, some metals tend to expand, thus leading to a mismatch between pipes and the fitting. In industries where the Annealed A234 WP11 Cl2 Fittings are to be exposed to high temperature environments, it is ideal that the alloy used in the manufacture of these fitting has a high tolerance for heat. For instance, if a Chromoly Alloy Steel A234 WP11 Elbow is used to change the direction of flow in a high temperature piping system, it must be able to retain its shape, specifically speaking its curvature and length.

Thus leading to a breakdown in the piping system. Unlike these metals, wrought alloy steels or carbon steel grades have good dimensional stability.

Because if the Buttweld A234 WP11 Cl1 Material expands, the elbow could dislocate the pipes fitted to it. Since the alloys used to manufacture these fittings exhibits a low rate of thermal expansion the threat of the SA234 Gr WP11 Fittings dislocating the piping lines could be eliminated. Typically, the specification covers several aspects such as forging operations, cooling treatments, and test procedures to be administered to the Alloy Steel A234 WP11 Tee.

| Standard Specification : | ASTM A234 WP11 Fittings |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

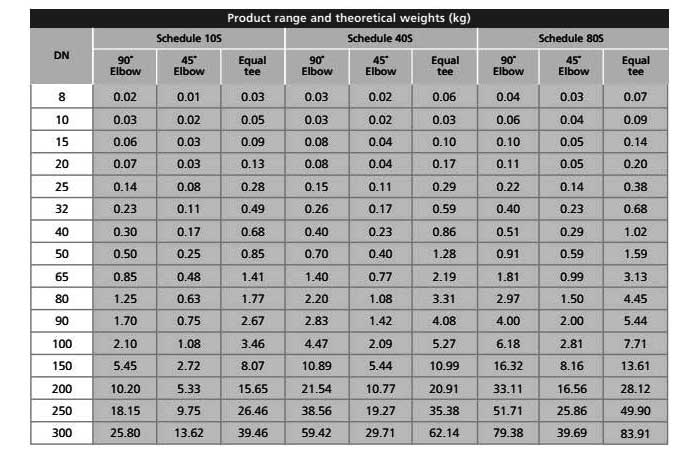

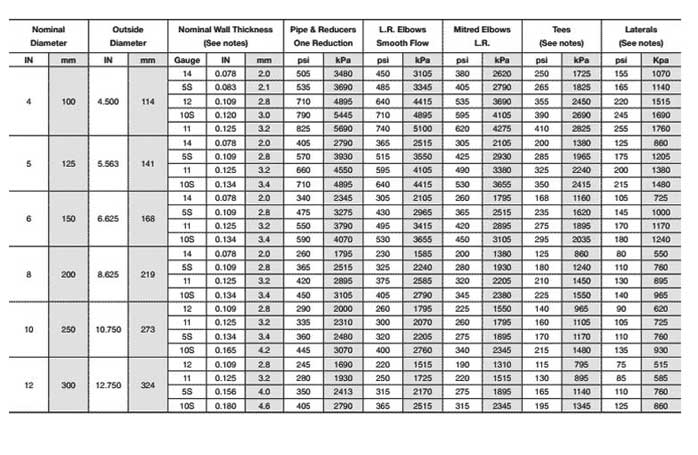

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Standard: | MSS-SP-43 Type b Fittings, MSS-SP-43 Type B Fittings, ANSI B16.28 Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, JIS B2312 Fittings |

| Fitting Machining Equipment: | Sand-blasting machine, Press machine, Pushing Machine, electric bevelling machine, Bending machine etc |

| Application: | Fabrication Industry Chemical Industry Water Pipeline Industry Natural Gas Industry Nuclear Power Plant Oil And Gas Industry |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Coating Fitting Faces : | Anti-rust Paint, Cold and Hot Dip Galvanized, Yellow Transparent, Oil Black Paint, Zinc Plated |

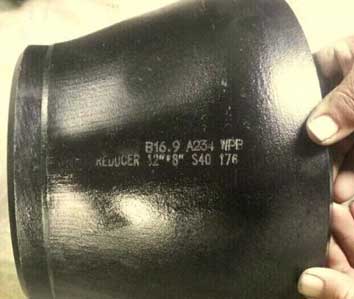

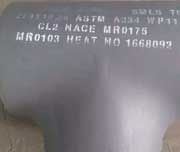

SA234 Gr WP11 Concentric Reducer

ASTM A234 Grade WP11 Equal Tee

Alloy Steel Grade WP11 45 Degree Elbow

A234 Grade WP11 90 Degree Elbow

A234 Grade WP11 End Cap

Alloy Steel Grade WP11 Short Radius Elbow

AS a234 WP11 LR Elbow

Alloy Steel WP11 Eccentric Reducer

ASTM A234 Grade WP11 Reducing Tee

ASTM A234 WP11 Lateral Tee

ASTM A234 Cl1 Equal Cross

A234 WP11 Welded Stub End

| WPB B,C,D,E, | WPC C,D,E, | WP11 CL1 | WP11 CL2, | WP11 CL3 |

|---|---|---|---|---|

| Carbon | 0.3 | 0.35 | 0.05–0.15 | 0.05–0.20 |

| Manganese | 0.29–1.06 | 0.29–1.06 | 0.30–0.60 | 0.30–0.80 |

| Phosporus | 0.05 | 0.05 | 0.03 | 0.04 |

| Sulfur | 0.058 | 0.058 | 0.03 | 0.04 |

| Silicon | 0.10 minimum | 0.10 minimum | 0.50–1.00 | 0.50–1.00 |

| Chromium | 0.4 | 0.4 | 1.00–1.50 | 1.00–1.50 |

| Molybdenum | 0.15 max | 0.15 max | 0.44–0.65 | 0.44–0.65 |

| Nickel | 0.4 | 0.4 | … | … |

| Copper | 0.4 | 0.4 | … | … |

| Others | Vanadium 0.08 | Vanadium 0.08 | … | … |

| Tensile Requirements | WPB | WP11CL1 | WP11CL3 |

| Tensile Strength, minimum, ksi[MPa] | 60-85 | 60-85 | 75-100 |

| (0.2% offset or 0.5% extension-under-load) | [415-585] | [415-585] | [520-690] |

| Yield Strength, minimum, ksi[MPa] | 32 | 30 | 45 |

| [240] | [205] | [310] |