-

-

send us mail

[email protected]

The ASTM A350 LF2 Fittings is classified into two classes i.e. Class 1 and Class 2. Although both classes of grade LF2 produced in accordance with the ASTM A350 specification are similar to each other. ( Both classes have the same chemical makeup and mechanical properties along with the same allowable stresses mentioned in ASME Codes.) The main feature that distinguishes ASTM A350 Lf2 Class 1 Pipe Fittings from grade LF2 Class 2 is its minimum applicable temperature. While the minimum applicable temperature is about -50°F for fitting that belong to LF2 Class 1, for LF2 Class 2 fitting, the minimum applicable temperature is -0°F. The minimum applicable temperature for both classes is also the standard temperature for the Charpy V-notch impact test to be performed on the ASME B16.11 A350 Lf2 Elbow.

ASTM A350 LF2 Fittings

Carbon Steel A350 Lf2 Forged Fitting

SA350 Gr Lf2 Fitting

Fittings categorized under Grade LF2 are known to have both moderate tensile strength as well as impact toughness properties.

Intended to be used for low temperature application, the specification lists down melting procedures. For instance, the alloy to make CS A350 Lf2 High Pressure Forged Fittings is melt processed by methods such as basic oxygen, electric furnace, open hearth, or vacuum induction melting. The Carbon Steel A350 Lf2 Forged Fitting could be furnished by heat treatment like normalizing, tempering, quenching and precipitation heat treatment. Moreover, the SA350 Gr Lf2 Fitting is to undergo a Heat analysis and product analysis as well as administered a Hardness test and hydrostatic test.

| Specification : | ASTM A350 LF2 Fittings |

| Forged Type : | NPT (Threaded), BSPT, BSPP. |

| Standard Of: | DIN2605, JISB2312 Fittings, PN, AWWA C207, BS4504, BS1560, BS, GB, ISO, ASME B16.47, ASME B16.38, MSS-SP-43 Fittings, JISB2313, ASME B16.25 Fittings, MSS SP-75 Fittings, JISB2311, IS 2062, DIN, ANSI B16.28, ASME B16.9 Fittings, BS10 |

| Connection Type : | Welding |

| Pressure: | Check Pressure Rating Of Socket, Threaded: 3000 LBS, 6000 LBS, 9000 LBS |

| Size Chart Of: | 1/8” NB to 4” NB (NPT-SW Fitting) |

| Dimensions Class: | 2000# Fittings, 3000# Fittings, 6000# Fittings, 9000# Fittings |

ASTM A350 Lf2 Forged Full Coupling

ASTM A350 Lf2 Socket Weld Cross

Carbon Steel ASTM A350 Threaded Pipe Nipple

ASTM A350 Lf2 Killed Carbon Steel Tee

ASTM A350 Gr Lf2 Carbon Steel Forged Half Coupling

ASTM A350 Class 1 And Class 2 Threaded Union

ASTM A350 Lf2 Class 1 Hex Plug

ASTM A350 Grade Lf2 Class 2 Street Elbow

LTCS ASTM A350 Gr Cl1 45 Deg Elbows

CS ASTM A350 Gr Lf2 90 Deg Elbows

SA350 Gr Lf2 Forged Cap

| Material Group | Common Name | Material Type | UNS | Forging Spec. | Casting Spec. Equivalent | DIN | DIN W. No | Application |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel | CS | C-Si | K03504 | A105 | A216-WCB | C22.8 DIN 17243 | 1.0460 | General non-corrosive service from -29ºC (-20ºF) to 425ºC (800ºF) |

| Low Temperature Carbon Steel | LTCS | C-Mn-Fe | K03011 | A350-LF2 | A352-LCB A352-LCC | TSTE 355 DIN 18103 | 1.0566 | General non-corrosive service from -46ºC (-50ºF) to 340ºC (650ºF), LF2 -46ºC ~ 425ºC |

| LTCS | Nickel Steel | 3.1/2Ni | K32025 | A350-LF3 | A352-LC3 | 10Ni14 | 1.5637 | -101ºC (150ºF) to 340ºC (650ºF) |

| Standard Impact Test Temperature for 10 * 10 millimeter Specimens | ||

|---|---|---|

| Gr./ Class | Test Temperature | |

| °F | °C | |

| LF1 | -20 | -29 |

| LF2 CL1 | -50 | -46 |

| LF2 CL2 | -0 | -18 |

| LF3 CL1 & CL2 | -150 | -101 |

| LF5 CL1 & CL2 | -75 | -59 |

| LF6 CL1 & CL2 | -60 | -51 |

| LF6 CL3 | -0 | -18 |

| LF9 | -100 | -73 |

| LF787 CL2 | -75 | -59 |

| LF787 CL3 | -100 | -73 |

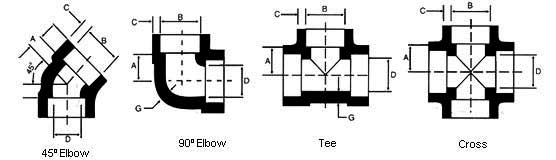

| Common Dimensions | Elbows, Tees & Crosses | Laterals, Couplings & Caps | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Nom. Pipe Size |

Min. Socket Diameter |

NPS. Bore Diameter |

A | B | C | D | E | F | G | H | J | K | L | M | N | O | P |

|

3000 Pressure Class

|

|||||||||||||||||

| 1/8 | 0.42 | 0.269 | 0.8 | 0.9 | 0.7 | 0.9 | 0.4 | 0.3 | 1.1 | 0.8 | 0.4 | 0.7 | |||||

| 1/4 | 0.555 | 0.364 | 0.8 | 0.9 | 0.7 | 0.9 | 0.4 | 0.3 | 1.1 | 0.9 | 1.62 | 0.7 | 1.25 | 0.3 | 0.4 | 0.9 | 0.8 |

| 3/8 | 0.69 | 0.493 | 0.9 | 1.1 | 0.7 | 1.1 | 0.5 | 0.3 | 1.1 | 1.1 | 1.88 | 0.8 | 1.44 | 0.4 | 0.4 | 1.3 | 0.8 |

| 1/2 | 0.855 | 0.622 | 1.1 | 1.3 | 0.8 | 1.3 | 0.6 | 0.4 | 1.3 | 1.3 | 2.06 | 0.8 | 1.62 | 0.4 | 0.4 | 1.3 | 0.8 |

| 3/4 | 1.065 | 0.824 | 1.3 | 1.5 | 1 | 1.5 | 0.8 | 0.5 | 1.5 | 1.5 | 2.53 | 1 | 2 | 0.4 | 0.6 | 1.5 | 1 |

| 1 | 1.33 | 1.049 | 1.4 | 1.8 | 1.1 | 1.8 | 0.9 | 0.6 | 1.6 | 1.9 | 2.94 | 1.1 | 2.38 | 0.5 | 0.6 | 1.8 | 1 |

| 1 1/4 | 1.675 | 1.38 | 1.7 | 2.3 | 1.2 | 2.3 | 1.1 | 0.7 | 1.6 | 2.3 | 3.44 | 1.3 | 2.81 | 0.6 | 0.6 | 2.3 | 1.1 |

| 1 1/2 | 1.915 | 1.61 | 1.9 | 2.5 | 1.3 | 2.5 | 1.3 | 0.8 | 1.6 | 2.5 | 3.88 | 1.4 | 3.19 | 0.7 | 0.6 | 2.5 | 1.1 |

| 2 | 2.406 | 2.067 | 2.3 | 3.1 | 1.7 | 3.1 | 1.5 | 1 | 2.1 | 3 | 4.69 | 1.6 | 3.88 | 0.8 | 0.7 | 3.1 | 1.3 |

| 2 1/2 | 2.906 | 2.469 | 2.9 | 3.6 | 2 | 4 | 1.6 | 1.1 | 2.1 | 3.6 | 6.88 | 2.1 | 5.94 | 1.2 | 0.7 | 3.6 | 1.3 |

| 3 | 3.535 | 3.068 | 3.3 | 4.3 | 2.4 | 4.6 | 2.3 | 1.3 | 2.1 | 4.4 | 8.5 | 2.5 | 7.25 | 1.3 | 0.7 | 5.1 | 1.4 |

| 4 | 4.545 | 4.026 | 4.2 | 5.8 | 3.1 | 5.8 | 2.6 | 1.6 | 2.4 | 5.5 | 13.6 | 4 | 12.1 | 2.5 | 0.8 | 6.8 | 1.6 |

|

6000 Pressure Class

|

|||||||||||||||||

| 3/8 | 0.69 | 0.344 | 1.1 | 1.3 | 0.9 | 1.3 | 0.6 | 0.4 | 1.1 | 1.3 | 2.12 | 0.9 | 1.5 | 0.3 | 0.4 | 1.3 | 0.9 |

| 1/2 | 0.855 | 0.464 | 1.3 | 1.5 | 1 | 1.5 | 0.8 | 0.5 | 1.3 | 1.5 | 2.56 | 1 | 2 | 0.4 | 0.4 | 1.5 | 0.9 |

| 3/4 | 1.065 | 0.612 | 1.5 | 1.8 | 1.1 | 1.8 | 0.9 | 0.6 | 1.5 | 1.8 | 3 | 1.1 | 2.38 | 0.5 | 0.6 | 1.8 | 1.1 |

| 1 | 1.33 | 0.815 | 1.7 | 2.3 | 1.3 | 2.3 | 1.1 | 0.7 | 1.6 | 2.3 | 3.5 | 1.3 | 2.81 | 0.6 | 0.6 | 2.3 | 1.2 |

| 1 1/4 | 1.675 | 1.16 | 2 | 2.5 | 1.3 | 2.5 | 1.3 | 0.8 | 1.6 | 2.5 | 3.94 | 1.4 | 3.19 | 0.7 | 0.6 | 2.5 | 1.2 |

| 1 1/2 | 1.915 | 1.338 | 2.3 | 3.1 | 1.7 | 3.1 | 1.5 | 1 | 1.6 | 3 | 4.75 | 1.7 | 3.88 | 0.8 | 0.6 | 3.1 | 1.3 |

| 2 | 2.406 | 1.687 | 2.5 | 3.4 | 1.8 | 3.4 | 1.6 | 1.1 | 2.1 | 3.6 | 6.88 | 2.1 | 6 | 1.3 | 0.7 | 3.6 | 1.4 |

| 2 1/2 | 2.906 | 2.125 | 3.2 | 4 | 2 | 4 | 2.3 | 1.3 | 2.1 | 4.3 | 8.5 | 2.5 | 7.5 | 1.5 | 0.7 | 5.1 | 1.4 |

| 3 | 3.535 | 2.624 | 3.7 | 4.8 | 2.4 | 4.6 | 2.5 | 1.4 | 2.1 | 5 | 8.5 | 2.5 | 7.25 | 1.3 | 0.7 | 5.1 | 1.6 |

| 4 | 4.545 | 3.438 | 4.5 | 6 | 3.1 | 5.8 | 2.6 | 1.6 | 2.4 | 6.3 | 13.6 | 4 | 12.1 | 2.5 | 0.8 | 6.8 | 1.8 |

| Steel Type | Grade (forging) | Grade (cast) | Composition | Min Temperature |

|---|---|---|---|---|

| Austenitic | A182, F316 | A351 CF8M | 18Cr, 8Ni, 2Mo | -196ºC |

| Nickel Based Steel | A350 LF3 | A352 LC3 | 3 1/2Ni | -101ºC |

| Nickel Based Steel | NO EQUIV | A352 LC2 | 2 1/2Ni | -73ºC |

| LTCS | NO EQUIV | A352 LC1 | 0.5Mo | -59ºC |

| LTCS | A350 LF2 | A352 LCB | Carbon Steel | -46ºC |

| Element | Composition, w.t % Grades | ||||||

|---|---|---|---|---|---|---|---|

| Carbon Steel LF1 | Carbon Steel LF2 | Carbon Steel LF3 | Carbon Steel LF5 | Carbon Steel LF6 | Carbon Steel LF9 | Carbon Steel LF787 | |

| C | ≤0.30 | ≤0.30 | ≤0.20 | ≤0.30 | ≤0.22 | ≤0.20 | ≤0.07 |

| Mn | 0.60-1.35 | 0.60-1.35 | ≤0.90 | 0.60-1.35 | 1.15–1.50 | 0.40–1.06 | 0.40–0.70 |

| P | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.025 | ≤0.035 | ≤0.025 |

| S | ≤0.040 | ≤0.040 | ≤0.040 | ≤0.040 | ≤0.025 | ≤0.040 | ≤0.025 |

| Si | 0.15-0.30 | 0.15-0.30 | 0.20-0.35 | 0.20-0.35 | 0.15-0.30 | ... | ≤0.40 |

| Ni | ≤0.40 | ≤0.40 | 3.30-3.70 | 1.00-2.00 | ≤0.40 | 1.60-2.24 | 0.70–1.00 |

| Cr | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.30 | 0.60–0.90 |

| Mo | ≤0.12 | ≤0.12 | ≤0.12 | ≤0.12 | ≤0.12 | ≤0.12 | 0.15-0.25 |

| Cu | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.40 | 0.75–1.25 | 1.00-1.30 |

| Cb | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 | ≥0.02 |

| V | ≤0.08 | ≤0.08 | ≤0.03 | ≤0.03 | 0.04-0.11 | ≤0.03 | ≤0.03 |

| N | ... | ... | ... | ... | 0.01–0.030 | ... | ... |

| Grade/Class | Tensile Strength | Yield Strength, min. | Elongation, min. | Hardness, max. | ||

|---|---|---|---|---|---|---|

| ksi | MPa | ksi | MPa | % | HBW | |

| Carbon Steel LF1 CL1 | 60-85 | 415–585 | 30 | 205 | 25 | 197 |

| Carbon Steel LF5 CL1 | 60-85 | 415–585 | 30 | 205 | 25 | 197 |

| Carbon Steel LF2 CL1 | 70–95 | 485–655 | 36 | 250 | 22 | 197 |

| Carbon Steel LF2 CL2 | 70–95 | 485–655 | 36 | 250 | 22 | 197 |

| Carbon Steel LF3 CL1 | 70–95 | 485–655 | 37.5 | 260 | 22 | 197 |

| Carbon Steel LF3 CL2 | 70–95 | 485–655 | 37.5 | 260 | 22 | 197 |

| Carbon Steel LF5 CL2 | 70–95 | 485–655 | 37.5 | 260 | 22 | 197 |

| Carbon Steel LF6 CL1 | 66–91 | 455–630 | 52 | 360 | 22 | 197 |

| Carbon Steel LF6 CL2 | 75–100 | 515–690 | 60 | 415 | 20 | 197 |

| Carbon Steel LF6 CL3 | 75–100 | 515–690 | 60 | 415 | 20 | 197 |

| Carbon Steel LF9 | 63–88 | 435–605 | 46 | 315 | 25 | 197 |

| Carbon Steel LF787 CL2 | 65-85 | 450-585 | 55 | 380 | 20 | 197 |

| Carbon Steel LF787 CL3 | 75-95 | 515-655 | 65 | 450 | 20 | 197 |