-

-

send us mail

[email protected]

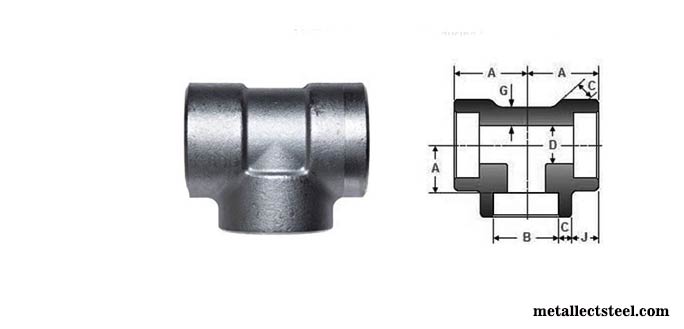

A pipe tee is a type of fitting that has three branches, with the fitting formed in the shape of the letter T. Similar to most fittings, the ASME B16.11 Reducing Tee is used in piping systems to change the direction of the flow. The difference between equal and unequal tee is the size of its diameter. The branch diameter of a Forged Screwed Unequal Tee is smaller than its main diameter. To illustrate, a reducing tees is usually described as NPS diameters, where the dimensions given are 4” x 4” x 3”. In this instance, the ANSI B16.9 Reducing Sw Tee Dimensions wherein 4 inches is the mainline pipe diameter, whereas 3 inches is the reducing branch. Both standards ASME B16.11 and ANSI B16.9 cover several aspects that could be used in the manufacture of fittings like Carbon Steel Threaded Reducing Tee. These aspects include overall dimensions, ratings, tolerances, marking as well as material requirements. However, the these two standards can be distinguished by the type of fitting produced. For instance, ASME B16.11 is a standard that provides recommendations for Forged Steel, Socket-Welding like the ASME B16.11 Socket Weld Reducing Tee and Threaded Fittings.

Check Reducings Tee, 1 X 1/2 NPS, 2 X 1/2, Socket, NPT, Class 3000#, 6000#, ANSI B16.11/ ASME B16.11 Dimensions

On the other hand, ANSI B16.9 is a standard that takes into account the parameters used to manufacture Factory-Made Wrought Steel Butt-welding Fittings. Applications of the Stainless Steel Threaded Reducings Tee include industries such as Water treatment systems, Sanitary tubing, Heat Exchangers, Chemical Industries, Machines and equipment, Power stations, Oil and gas transmissions as well as petroleum and Oil refining.

| Specification : | ASME B16.11 Reducing Tee |

| Size: | 1/8” NB to 4” NB (Screwed-Socket) |

| Forged Type : | NPT (Threaded), BSPT, BSPP. |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Standard: | JISB2311, IS 2062, DIN, ANSI B16.28, ASME B16.9, BS10, ASME B16.47, ASME B16.38, MSS-SP-43, JISB2313, ASME B16.25, MSS SP-75, DIN2605, JISB2312, PN, AWWA C207, BS4504, BS1560, BS, GB, ISO |

| Connection Type : | Welding |

| Pressure Rating: | Socket, Threaded: 3000 LBS, 6000 LBS, 9000 LBS |

| Mills And Origin : | Europe, Russian, USA, India, Japanese |

1 X 1/2 NPS Socket Weld Reducing Tee

2 X 1 NPS 3000# ASME B16.11 Reducing Tee

3/4 To 1/2 NPS 6000# Forged Reducings Tee

3/6 x 1/2 9000# Socket Weld Unequal Tee

1-1/2 inch 6000# 304L Stainless Steel Socket Weld Reducing Tee

1/2 inch Class 6000 Socket Weld Reducing Tee

ASTM A182 SS Socket weld Reducing Tee

10 x 10 Weld Sch 10 Threaded Pipe Reducing Tee

1/2 To 1/2 Inch Carbon Steel Threaded Reducing Tee

1/2 To 1/2 Inch 3000# Threaded Reducing Tee

2 inch Sch 40 Stainless Steel Threaded Reducing Tee

1/2 To 2/3 Inch Forged Threaded Reducing Tee

| Normal Pipe Size | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| NPS | Socket WT |

Body WT |

Center to bottom of socket |

| C | G | A | |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 |

4.80 | 19.5 |

| 3/4 | 6.95 6.05 |

5.55 | 22.5 |

| 1 | 7.90 6.95 |

6.35 | 27 |

| 1.1/4 | 7.90 6.95 |

6.35 | 32 |

| 1.1/2 | 8.90 7.80 |

7.15 | 38 |

| 2 | 10.90 9.50 |

8.75 | 41 |

General notes:

| NPS | B | L1 | C | G | D | A | Weight |

|---|---|---|---|---|---|---|---|

| inch | MilliMeter | socket | MilliMeter | MilliMeter | MilliMeter | MilliMeter | ~Kilogram/pce |

| 1/4 3/8 1/2 3/4 |

14.20 17.60 21.80 27.20 |

9.53 9.53 9.53 12.50 |

3.30 3.51 4.09 4.27 |

3.02 3.20 3.73 3.91 |

8.86 12.14 15.42 20.55 |

11.11 13.49 15.88 19.05 |

0.11 0.16 0.34 0.41 |

| 1 1¼ 1½ 2 |

33.90 42.70 48.80 61.20 |

12.50 12.50 12.50 16.00 |

4.98 5.28 5.54 6.05 |

4.55 4.85 5.08 5.54 |

26.26 34.67 40.51 52.12 |

22.23 26.99 31.75 38.10 |

0.65 0.95 1.33 2.20 |

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

| Nirmal Pipe Size | Minimum Length of Thread | Outside Dia of Band D |

Center to End A |

Minimum WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

General notes:

| #2000 | NPS | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.740 | 1.058 | 1.375 | 1.740 | 2.883 | 7.750 | 11.313 | 19.125 | |

#3000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.250 | 0.290 | 0.500 | 0.750 | 1.188 | 1.988 | 2.235 | 3.000 | 4.930 | 7.375 | 13.588 | 19.063 | |

#6000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.250 | 0.640 | 0.500 | 1.438 | 2.188 | 2.785 | 4.688 | 5.750 | 9.500 | 15.000 | 30.563 | – | |

NPS |

1/2 to 2½ |

3 to 3½ |

4 |

5 to 8 |

10 to 18 |

20 to 24 |

26 to 30 |

32 to 48 |

Outside Dia |

+1.6 |

1.6 |

1.6 |

+2.4 |

+4 |

+6.4 |

+6.4 |

+6.4 |

Inside Dia at End |

0.8 |

1.6 |

1.6 |

1.6 |

3.2 |

4.8 |

+6.4 |

+6.4 |

Center to End (C / M) |

2 |

2 |

2 |

2 |

2 |

2 |

3 |

5 |