-

-

send us mail

[email protected]

Regarded to be one of the most versatile fittings across several industries, an elbows is used to bring about directional flow in piping systems. When one talks about ASME B16.11 Elbow, it is in reference to the length of a pipe with a sharp bend in it. A pipe elbow is a fitting installed between two lengths of pipe or tube allowing a change of direction, usually in the 90° or 45° or a 22.5° direction. The ability of a custom made elbows, including the 45 Degree Socket Weld Elbow is very unique and provides installers with features such as unmatched flexibility and convenience while at the same time simplifying the fitting of custom joints to a great extent.

Buy 45 / 90 Elbows Size 1 1/2 Inch To 2 Inch SW, NPT, Class 3000#, 6000# ASME B16.11, ASTM A105 At Low Price

Using a 45 deg Screwed Elbow Weight Chart the manufacturer could custom make elbows using various materials such as Steel, Carbon steel, Stainless Steel, Copper, Aluminium, Brass, etc. Frequently used in pressurized applications, the Stainless Steel Socket Weld 45 Degree Elbow is available in various shapes and sizes for use in various applications. The ASME B16.11 Standard that used in the manufacture of forged fittings such as an elbows covers several bases such as ratings, Threaded 90 Deg Elbows Dimensions, tolerances, marking and material requirements. The requirements covered by this standard also include socket-welding and threaded 1/4 Npt 90 Degree Elbow.

| Specification : | ASME B16.9 11 Elbow |

| Size Chart Of Threaded Elbow: | 1/8” NB to 4” NB (Screwed-Socket) |

| Forged Type : | NPT (Threaded), BSPT, BSPP. |

| Elbow SW Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Standard Of 45 Degree Npt Elbow: | JISB2311, IS 2062, DIN, ANSI B16.28, ASME B16.9, BS10, ASME B16.47, ASME B16.38, MSS-SP-43, JISB2313, ASME B16.25, MSS SP-75, DIN2605, JISB2312, PN, AWWA C207, BS4504, BS1560, BS, GB, ISO |

| NPT 90 Elbow Connection Type : | Welding |

| Elbow 90 Deg SW Pressure: | Check Pressure Rating Of Socket, Threaded: 3000 LBS, 6000 LBS, 9000 LBS |

| Mills And Origin : | Europe, India, Japanese, Russian, USA |

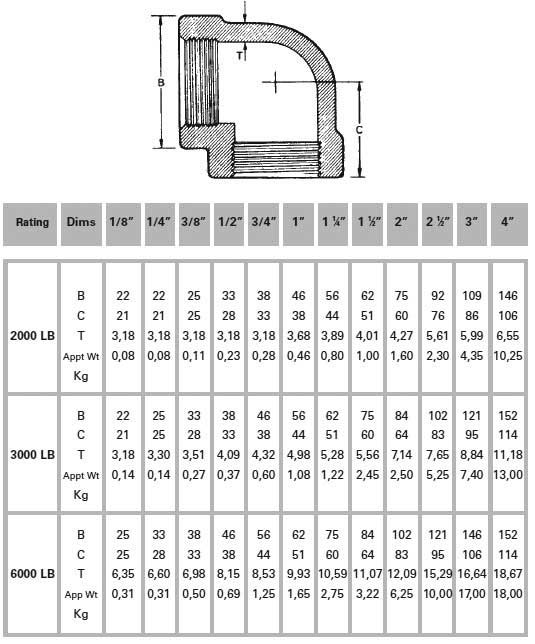

| Class 2000 | Nominal Pipe Size | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.740 | 1.058 | 1.375 | 1.740 | 2.883 | 7.750 | 11.313 | 19.125 | |

Class 3000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.250 | 0.290 | 0.500 | 0.750 | 1.188 | 1.988 | 2.235 | 3.000 | 4.930 | 7.375 | 13.588 | 19.063 | |

Class 6000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.250 | 0.640 | 0.500 | 1.438 | 2.188 | 2.785 | 4.688 | 5.750 | 9.500 | 15.000 | 30.563 | – | |

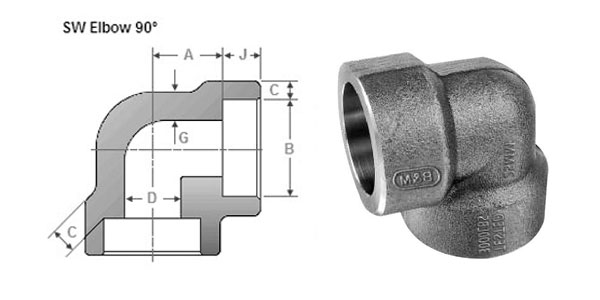

| NPS | Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| B | J | D | C | G | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

3.75 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

3.90 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

4.55 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

4.85 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

5.10 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

5.55 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

7.00 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

7.60 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

8.55 |

1-1/2 inch Socket 316L Socket Weld 45 Degree Elbow

2 Inch SW 6000# Pipe Elbow 3000lb

3 Inch SW 3000# 304L 45 Degree Socket Weld Elbow

3/4 x 1/2 inch 2000# SW 90 Degree Elbow

1 inch 9000# 304L SS ASME B16.11 90 Degree Elbow

2 inch 2000# Duplex Steel 2205 Forged Socket Weld Elbow 90 Degree

1/8 inch 150# 45 Degree Threaded Elbow

1-1/2 inch NPT x NPS Threaded Elbow Class 3000

1/8 inch 3000# Threaded Reducing Elbow

1/8 inch 6000# 90 Degree Elbow Female Threaded

1/4 Npt 90 Degree Elbow

12 inch Stainless Steel 90 Degree Threaded Elbow

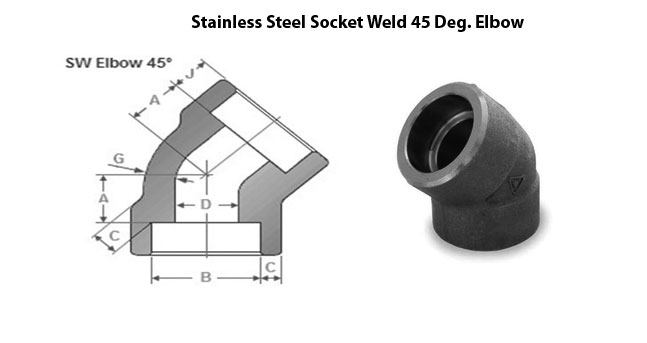

| NPS | Socket Bore |

Depth Socket |

Bore diameter |

Socket wall thickness |

Body wall thickness |

Center to bottom of socket A |

|

| B | J | D | C | G | 45° | ||

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

3.75 | 11.5 | |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

3.90 | 12.5 | |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

4.55 | 14 | |

| 1¼ | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

4.85 | 17 | |

| 1½ | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

5.10 | 21 | |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

5.55 | 25 | |

| 2½ | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

7.00 | 29 | |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

7.60 | 31.5 | |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

8.55 | 41.5 | |

| NPS | Min Length of Thread |

Outside Dia of Band |

Min WT |

Center to End | |

| B | J | D | G | 45° C |

|

| 1/2 | 10.9 | 13.6 | 38 | 4.09 | 25 |

| 3/4 | 12.7 | 13.9 | 46 | 4.32 | 28 |

| 1 | 14.7 | 17.3 | 56 | 4.98 | 33 |

| 1.1/4 | 17 | 18 | 62 | 5.28 | 35 |

| 1.1/2 | 17.8 | 18.4 | 75 | 5.56 | 43 |

| 2 | 19 | 19.2 | 84 | 7.14 | 44 |

| 2.1/2 | 23.6 | 28.9 | 102 | 7.65 | 52 |

| 3 | 25.9 | 30.5 | 121 | 8.84 | 64 |

| 4 | 27.7 | 33 | 152 | 11.18 | 79 |

| NPS | Min Length of Thread |

Outside Dia of Band |

Min WT |

Center to End | |

| B | J | D | G | 45° C |

|

| 1/2 | 10.9 | 13.6 | 46 | 8.15 | 28 |

| 3/4 | 12.7 | 13.9 | 56 | 8.53 | 33 |

| 1 | 14.7 | 17.3 | 62 | 9.93 | 35 |

| 1.1/4 | 17 | 18 | 75 | 10.59 | 43 |

| 1.1/2 | 17.8 | 18.4 | 84 | 11.07 | 44 |

| 2 | 19 | 19.2 | 102 | 12.09 | 52 |

| 2.1/2 | 23.6 | 28.9 | 121 | 15.29 | 64 |

| 3 | 25.9 | 30.5 | 146 | 16.64 | 79 |

| 4 | 27.7 | 33 | 152 | 18.67 | 79 |

Class 2000 |

Nominal Pipe Size |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| A | – | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 3 | 3 3/8 | 4 3/16 | |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| Wt | – | 0.198 | 0.283 | 0.500 | 0.773 | 1.013 | 1.550 | 2.180 | 3.140 | 6.500 | 10.925 | 26.675 | |

| Class 3000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 1/2 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| Wt | 0.236 | 0.350 | 0.592 | 0.973 | 1.355 | 2.265 | 2.407 | 3.500 | 5.920 | 11.900 | 14.438 | 31.975 | |

| Class 6000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 3/16 | 4 1/2 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | 6 | |

| Wt | 0.250 | 0.625 | 1.023 | 1.625 | 2.625 | 3.500 | 6.750 | 7.500 | 13.438 | 20.875 | 39.050 | 38.000 | |

| NPS | Min Length of Thread |

Outside Dia of Band |

Min WT |

Center to End | ||

| B | J | D | G | 90° A |

45° C |

|

| 1/2 | 10.9 | 13.6 | 46 | 8.15 | 38 | 28 |

| 3/4 | 12.7 | 13.9 | 56 | 8.53 | 44 | 33 |

| 1 | 14.7 | 17.3 | 62 | 9.93 | 51 | 35 |

| 1.1/4 | 17 | 18 | 75 | 10.59 | 60 | 43 |

| 1.1/2 | 17.8 | 18.4 | 84 | 11.07 | 64 | 44 |

| 2 | 19 | 19.2 | 102 | 12.09 | 83 | 52 |

| 2.1/2 | 23.6 | 28.9 | 121 | 15.29 | 95 | 64 |

| 3 | 25.9 | 30.5 | 146 | 16.64 | 106 | 79 |

| 4 | 27.7 | 33 | 152 | 18.67 | 114 | 79 |