-

-

send us mail

[email protected]

It is mandated that the IBR Flange is to be inspected by a company that has been approved by the Central Boiler Board or CBB. The CBB has to certify all pressure equipment, including components such as flanges using steam. Only those components for e.g. IBR Approved Blind Flanges that have been approved could be imported into India. Industries such as fossil and nuclear energy require good quality certified components to be used for their applications. The materials used for producing these flanges according to IBR Pipe Flange Manufacturers In India include different grades of stainless steel, alloy steel as well as carbon steel.

The Indian Boiler Regulation or shortened as IBR defines a set of standards with the intention of being used for not only product design and construction but also inspection and testing methods as well.

There are several advantages to using IBR components. Firstly there is minimal to no risk of explosion when the imported Low Alloy Steel IBR Approved Flange has been manufactured using the appropriate IBR material. Secondly, the using an IBR approved flanges takes care of the legal aspects namely the compliance, which assures its user a peace of mind, while ensuring the product also has a longer service life with a lesser chance of breakdown. Lastly, safety assurance is a huge part of IBR approval, wherein a government certified third party inspects the produced Stainless Steel IBR Flanges for faults and compliance to safety regulations.

| Specification : | IBR Flanges |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Production Process: | Heat Treated, Machined, Forged |

| Coating Flanges Faces : | Zinc Plated, Yellow Transparent, Anti-rust Paint, Cold and Hot Dip Galvanized, Oil Black Paint |

| Standards: | JIS Flanges, ISO Flanges, GOST Flanges, UNI Flanges, AWWA Flanges, MSS SP44 Flanges, ASME B16.5 Flanges, ASME B16.38 Flanges, EN-1092 Flanges, BS10 Flanges, DIN Flanges, PN Flanges, ASME B16.47 (Series A, Series B) Flanges |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Common Types of Flanges : | Flanges 150 LB WNRF Class 300 RTJ 600# BLRF Class 900 SORF |

| Supporting Flanges Material: | Gasket, Flanges Bolts, Ring Joint |

| Application: | Water Pipeline Industry Chemical Industry Nuclear Power Plant Natural Gas Industry Oil And Gas Industry Fabrication Industry |

| Design For Size: | ANSI, EN, ASA, DIN, JIS, ASME, BS, PN |

| Flanges Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine, Press machine, electric bevelling machine etc |

| Connect Type: | LJF, RF, FF, LMF, SMF, RTJ |

IBR Approved Reducing Flanges

IBR Approved Weld Neck Flanges

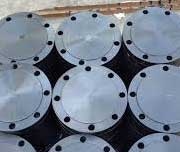

IBR Approved Blind Flanges

IBR Approved Flat Face Flanges

IBR Approved RTJ Flanges

IBR Approved Raised Face Flanges

IBR Approved Socket Weld Flanges

IBR Approved Slip On Flanges

IBR Approved Orifice Flanges

IBR Approved Spectacle Flanges

| CLASS | NPS | IBR Approved SORF Flanges | IBR Approved NPT Flanges | IBR Approved SW Flanges | IBR Approved Loose Flanges | IBR Approved BLRF Flanges | IBR Approved WN Flanges |

|---|---|---|---|---|---|---|---|

| 150# | ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 | |

| CLASS | NPS | SORF | NPT Flanges | SW | Loose | BLRF | WN |

| 300# | ½ | 2 | 2 | 3 | 2 | 2 | 2 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1 | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4 | 4.5 | 6 | 5 | |

| 1½ | 6.5 | 6.5 | 6 | 6.5 | 7 | 7 | |

| 2 | 7 | 7 | 7 | 7 | 8 | 9 | |

| 2½ | 10 | 10 | 10 | 10 | 12 | 12 | |

| 3 | 13 | 14 | 13 | 14.5 | 16 | 18 | |

| 3½ | 17 | 17 | 17 | 17 | 21 | 20 | |

| 4 | 23.5 | 24 | 22 | 24 | 28 | 26.5 | |

| 5 | 29 | 31 | 28 | 28 | 37 | 36 | |

| 6 | 39 | 39 | 39 | 39 | 50 | 45 | |

| 8 | 58 | 58 | 58 | 58 | 81 | 69 | |

| 10 | 81 | 81 | 81 | 91 | 124 | 100 | |

| 12 | 115 | 115 | 115 | 140 | 185 | 142 | |

| 14 | 165 | 165 | 165 | 190 | 250 | 206 | |

| 16 | 210 | 220 | 190 | 234 | 315 | 250 | |

| 18 | 253 | 280 | 250 | 305 | 414 | 320 | |

| 20 | 315 | 325 | 315 | 375 | 515 | 400 | |

| 22 | 370 | 370 | 370 | 435 | 640 | 465 | |

| 24 | 490 | 490 | 475 | 550 | 800 | 580 | |

| CLASS | NPS | SORF | NPT Flanges | SW | Loose | BLRF | WN |

| 600# | ½ | 2 | 2 | 2 | 2 | 3 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1 | 4 | 4 | 4 | 4 | 4 | 4 | |

| 1¼ | 5 | 5 | 5 | 5 | 6 | 6 | |

| 1½ | 7 | 7 | 7 | 7 | 8 | 8 | |

| 2 | 9 | 9 | 9 | 9 | 10 | 12 | |

| 2½ | 13 | 13 | 13 | 12 | 15 | 18 | |

| 3 | 16 | 16 | 16 | 15 | 20 | 23 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 37 | 37 | 37 | 36 | 41 | 42 | |

| 5 | 63 | 63 | 63 | 63 | 68 | 68 | |

| 6 | 80 | 80 | 80 | 78 | 86 | 81 | |

| 8 | 115 | 15 | 15 | 112 | 140 | 120 | |

| 10 | 177 | 177 | 177 | 195 | 231 | 190 | |

| 12 | 215 | 215 | 215 | 240 | 295 | 226 | |

| 14 | 259 | 259 | 259 | 290 | 378 | 347 | |

| 16 | 366 | 366 | 366 | 400 | 527 | 481 | |

| 18 | 476 | 476 | 476 | 469 | 665 | 555 | |

| 20 | 612 | 612 | 612 | 604 | 855 | 690 | |

| 22 | 590 | 590 | 590 | 670 | 1000 | 720 | |

| 24 | 876 | 876 | 876 | 866 | 1250 | 977 |

| ASME | Stainless Steel Flanges Pressure Rating | ||||||

| Temperature °F | 150 LB | 300 LB | 400 LB | 600 LB | 900 LB | 1500 LB | 2500 LB |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

| Standard | Class | Dia. | Bolt Circle Dia. | Number of Bolts | Bolt Size | Dia. of Bolt Hole |

|---|---|---|---|---|---|---|

| AS4087 | PN14 | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C | 95 | 67 | 4 | 13 | 14 |

| Table D | 95 | 67 | 4 | 13 | 14 | |

| Table E | 95 | 67 | 4 | 13 | 14 | |

| Table F | 95 | 67 | 4 | 13 | 14 | |

| Table H | 114 | 83 | 4 | 16 | 17 | |

| Table J | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 | ANSI 150 | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 | 80 | 55 | 4 | M10 | 11 |

| PN10 | 95 | 65 | 4 | M12 | 14 | |

| PN16 | 95 | 65 | 4 | M12 | 14 | |

| PN20 | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 | 95 | 65 | 4 | M12 | 14 | |

| PN40 | 95 | 65 | 4 | M12 | 14 |