-

-

send us mail

[email protected]

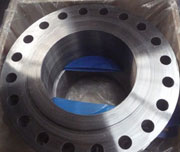

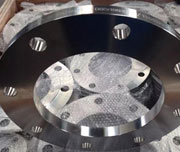

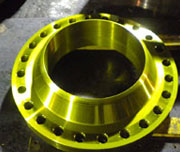

ASME B16.5 is a standard that covers both different types of flanges and flange fittings for piping systems. One such type is the weld neck ASME B16.5 Class 300 Flangewhich consists of a circular fitting that has a protruding rim around its circumference. The rim of the flanges has a series of drilled holes that allow the flanges to be fixed to another flange with the use of bolts. Generally machined from a forging, it is not unusual for these Welding Neck Flange ASME B16.5 Class 300 butt welded to a pipe in a system.

One of the parameters covered by the standard, which was revised in 1996 includes its pressure-temperature ratings for e.g Class 300 Pipe Flanges Pressure Rating. Apart from the ratings, the specification takes into account many parameters such as materials, tolerances, dimensions for e.g. 1 inch Flanges 300# Dimension, marking, testing. Moreover, the methods of designating openings for pipe flanges and flanged fittings are also a part of the specification.

Get 4 Inch, SCH-40 * SCH-80, WN, FF, ASTM A105n, Forged, RF, ASME 16.5 300#.

Typically the ASME B16.5 is a standard that takes into consideration flanges with the following rating class designations i.e. # 150, # 300, # 400, # 600, # 900, # 1500, and # 2500. Carbon Steel Class 300 Pipe Flanges are available across the market in sizes that range from NPS 1/2 through NPS 24, their requirements given in both metric as well as in U.S units. The Standard is limited to different flanges and their corresponding fittings made from cast or forged materials, or plate materials. Also included in this Standard are requirements and recommendations regarding 300 Lb Stainless Steel Flange bolting, flanges gaskets, along with flanges joints.

| Specification : | ASME B16.5 Class 300 Flange |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Production Process: | Forged, Heat Treated and Machined |

| Supporting Flange Material: | Flange Bolts, Ring Joint, Gasket |

| Common Types of Classes 300LB Flange : | Flange 300 LB WNRF Classes 300 RTJ 300# BLRF Classes 300 SORF |

| Connect Type Type: | SMF, RF, FF, LJF, LMF, RTJ |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Application: | Natural Gas Industry Water Pipeline Industry Chemical Industry Oil And Gas Industry Fabrication Industry Nuclear Power Plant |

| Standards : | ASME B16.38 Flange, UNI Flange, ASME B16.47 (Series A, Series B) Flange, PN Flange, ISO Flange, JIS Flange, MSS SP44 Flange, EN-1092 Flange, BS10 Flange, ASME B16.5 Flange, AWWA Flange, DIN Flange, GOST Flange |

| Design For Size: | ANSI, ASME, ASA, PN, JIS, EN, DIN, BS |

| Machining Equipment: | Electric bevelling machine, Bending machine, Press machine, Pushing Machine, Sand-blasting machine etc |

| Coating Flanges Faces : | Anti-rust Paint, Zinc Plated, Oil Black Paint, Yellow Transparent, Cold and Hot Dip Galvanized |

| NPS | Outside diameter of flanges |

Mini. thick. of flanges |

Overall Length | Bolt Circle |

No. and Size of Holes |

O.D. of raised face |

|||

|---|---|---|---|---|---|---|---|---|---|

| Welding neck |

Slip-on & socket welding |

Lap Joint | |||||||

| O | Q | Y | Diammeter | Number | diameter | R | |||

| 1/2 | 95 | 14.3 | 52.4 | 22.2 | 22.2 | 666.5 | 4 | 15 | 35 |

| 3/4 | 117 | 15.9 | 57.2 | 25.4 | 25.4 | 82.4 | 4 | 19 | 43 |

| 1 | 124 | 17.5 | 61.9 | 27.0 | 27.0 | 89.0 | 4 | 19 | 51 |

| 1-1/4 | 133 | 19.1 | 65.1 | 27.0 | 27.0 | 98.5 | 4 | 19 | 64 |

| 1-1/2 | 156 | 20.7 | 68.3 | 30.2 | 30.2 | 114.5 | 4 | 22 | 73 |

| 2 | 165 | 22.3 | 69.8 | 33.3 | 33.3 | 127.0 | 8 | 19 | 92 |

| 2-1/2 | 190 | 25.4 | 76.2 | 38.1 | 38.1 | 149.0 | 8 | 22 | 105 |

| 3 | 210 | 28.6 | 79.4 | 42.9 | 42.9 | 168.0 | 8 | 22 | 127 |

| 4 | 254 | 318 | 85.7 | 47.6 | 47.6 | 200.0 | 8 | 22 | 157 |

| 5 | 279 | 35.0 | 98.4 | 50.8 | 50.8 | 235.0 | 8 | 22 | 186 |

| 6 | 313 | 36.6 | 98.4 | 52.4 | 52.4 | 270.0 | 12 | 22 | 216 |

| 6 | 381 | 413 | 111.1 | 61.9 | 91.9 | 330.0 | 12 | 25 | 270 |

| 10 | 444 | 47.7 | 117.5 | 66.7 | 95.3 | 387.5 | 16 | 29 | 324 |

| 12 | 521 | 50.8 | 130.2 | 73.0 | 101.6 | 451.0 | 16 | 32 | 381 |

| 14 | 584 | 54.0 | 142.9 | 76.2 | 111.1 | 514.5 | 20 | 32 | 413 |

| 16 | 648 | 57.2 | 146.0 | 82.6 | 120.7 | 571.5 | 20 | 35 | 470 |

| 18 | 711 | 60.4 | 158.8 | 88.9 | 130.2 | 628.5 | 24 | 35 | 533 |

| 20 | 775 | 63.5 | 161.9 | 95.2 | 139.7 | 686.0 | 24 | 35 | 584 |

| 24 | 914 | 69.9 | 168.3 | 106.4 | 152.4 | 843.0 | 24 | 41 | 692 |

300# Rf Threaded Flange

ANSI B16.5 Class 300 Lap Joint Flange

Class 300 Long Weld Neck Flange

ANSI/ASME B16.5 Class 300 Forged Flange

Class 300 Plate Flange

ANSI 300 Square Flange

Class 300 Puddle Flanges

ANSI 300 Flange Adapter

classes 300 Expander Flange

ANSI B16.5 Class 300 Socket-weld Flange

300# High hub Blind Flange

Welding Neck Flange ANSI B16.5 300 Lbs

| CLASS | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

| 300 lb | ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 |

Temperature (in F°) |

300# |

100 |

740 |

200 |

680 |

300 |

655 |

400 |

635 |

500 |

605 |

600 |

570 |

650 |

550 |

700 |

530 |

750 |

505 |

800 |

410 |

850 |

320 |

900 |

230 |

950 |

135 |

1000 |

85 |

Hydrostatic Test Pressure (psig) |

1125 |

Class 300 Flanges |

||||

|---|---|---|---|---|

Nominal Pipe Size |

# Bolts or Studs |

Dia of Bolts or Studs |

Length of Stud |

|

1/16 RF |

RTJ |

|||

1/2 |

4 |

0.50 |

2-1/4 |

- |

3/4 |

4 |

0.50 |

2-1/2 |

- |

1 |

4 |

0.50 |

2-1/2 |

3 |

1-1/4 |

4 |

0.50 |

2-3/4 |

3-1/4 |

1-1/2 |

4 |

0.50 |

2-3/4 |

3-1/4 |

2 |

4 |

0.63 |

3-1/4 |

3-3/4 |

2-1/2 |

4 |

0.63 |

3-1/2 |

4 |

3 |

4 |

0.63 |

3-1/2 |

4 |

3-1/2 |

8 |

0.63 |

3-1/2 |

4 |

4 |

8 |

0.63 |

3-1/2 |

4 |

5 |

8 |

0.75 |

3-3/4 |

4-1/4 |

6 |

8 |

0.75 |

4 |

4-1/2 |

8 |

8 |

0.75 |

4-1/4 |

4-3/4 |

10 |

12 |

0.88 |

4-1/2 |

5 |

12 |

12 |

0.88 |

4-3/4 |

5-1/4 |

14 |

12 |

1.00 |

5-1/4 |

5-3/4 |

16 |

16 |

1.00 |

5-1/4 |

5-3/4 |

18 |

16 |

1.13 |

5-3/4 |

6-1/4 |

20 |

20 |

1.13 |

6-1/4 |

6-3/4 |

24 |

20 |

1.25 |

6-3/4 |

7-1/4 |

| NPS NPS (inch) |

Class 300 | ||||

|---|---|---|---|---|---|

| Diammeter of Flange (inch) |

No. of Bolts |

Diammeter of Bolts (inch) |

Diammeter of Bolt Holes (inch) |

Bolt Circle (inch) |

|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |