ISO Approved Aluminum Alloy Plate, UNS A96063 Sheet Distributor In India

Aluminium Sheet / Plate is made up of aluminum based metallic products. There are different grades of aluminum used to producing the sheets and Aluminium Coils. The plates and sheets are created by pressing the raw material under high pressure rollers. The UNS A96063 Sheet Plate and other designations are provided to control the properties and qualities of the products. There are different standards such as the DIN 3.1254 Sheet to make sure that the standards are understood universally. The ASTM B209 Aluminium Sheet belongs to the specification of heat treatable aluminum alloys. There are plates made up of hot rolling or cold rolling procedures. The Aluminium Hot Rolled Sheet is rolled under elevated temperatures whereas the cold rolled sheets are processed under room temperatures.

The applications differ and include packaging, transportation, panels for automobile bodies, cookware, gutters and in airframe bodies. There are different types such as the Aluminium Diamond Plate and the polished plates. The different applications require the different forms of the aluminum sheets and plates such as the Aluminium Slitting Coils. The material can be recycled continuously without losing the properties of new aluminum. The material is used in armor plate manufacturing where the lightweight is an advantage. The Aluminium Shim Sheet is used with ease because it is strong enough. Some grades of the aluminum plates are very strong at supercold temperatures. The Aluminium Perforated Sheet and other finishes are preferred for different applications. The perforation further reduces the weight of the application. Please contact us for any inquiries on the ASME SB209 Aluminium Cold Rolled Sheet Plate or the hot rolled ones.

Table of Content - ASTM B209 Aluminium Sheet Sizes And Schedule Specifications - Aluminum Alloy Sheet Chemical Compatibility - Perforated Aluminium Sheet Mechanical Behaviour - Basic Types Of Aluminium Sheet - DIN 3.1254 Sheet Physical Property - Aluminium Coils Weight Chart

ASTM B209 Aluminium Sheet Sizes And Schedule Specifications

| Specifications | ASTM / ASME SB209 |

| Width | 1000 milimeter to 1500 milimeter |

| Size | 1000 milimeter x 60610 milimeter, 1220 milimeter x 2440 milimeter, 1500 milimeter x 3000 milimeter, 60610 milimeter x 60610 milimeter, 60610 milimeter x 4000 milimeter |

| Length | 1000 milimeter to 6000 milimeter |

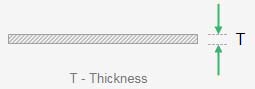

| Thickness | 0.1milimeter to 12 milimeter Thk |

| Material | Aluminium |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

Buy DIN 3.1254 Sheet At Best Price In Bhopal, India, Specification Of Aluminum Alloy Sheet

Aluminum Alloy Sheet Chemical Compatibility

| Grade | Mn | Si | Ti | Fe | Mg | Cu | Al | Zn | Others(Total) | Cr |

| Aluminium | 0.15 | 0.40 – 0.80 | 0.15 | 0.70 | 0.8-1.2 | 0.15-0.40 | Balance | 0.25 | 0.15 | 0.04-0.35 |

Perforated Aluminium Sheet Mechanical Behaviour

Aluminium Coils Types, Check ASTM B209 Aluminium Sheet Chemical Composition, Aluminium Hot Rolled Sheet Mechanical properties, Call Now to Get Aluminium Diamond Plate Free sample.

| Temper | Tensile | Hardness | ||||

| Ultimate | Yield | Elongation | Brinell | |||

| MPA | KSI | KSI | MPA | % | ||

| T6, T651 | 310 | 45 | 21 | 145 | 25 | 65 |

Basic Types Of Aluminium Sheet

Aluminium Coils

Aluminium Coils

UNS A96063 Sheet Plate

UNS A96063 Sheet Plate

DIN 3.1254 Sheet

DIN 3.1254 Sheet

Aluminum Alloy Sheet

Aluminum Alloy Sheet

ASTM B209 Aluminium Sheet

ASTM B209 Aluminium Sheet

Aluminium Hot Rolled Sheet

Aluminium Hot Rolled Sheet

Aluminium Diamond Plate

Aluminium Diamond Plate

Aluminum Checkered Plate

Aluminum Checkered Plate

Aluminium Slitting Coils

Aluminium Slitting Coils

Aluminium Shim Sheet

Aluminium Shim Sheet

Aluminium Perforated Sheet

Aluminium Perforated Sheet

Aluminum Alloy Plate

Aluminum Alloy Plate

DIN 3.1254 Sheet Physical Property

Buy Aluminum Checkered Plate Certified & Tested Materials, We provide Multiple Payment Options Of Aluminium Sheet, Aluminium Slitting Coils, Physical Properties Of Aluminium Shim Sheet.

| Physical Property | Value |

| Modulus of Elasticity | 69 GPa |

| Density | 2,70 g/cm³ |

| Thermal Conductivity | 170 W/m.K |

| Melting Point | 582 °C |

| Electrical Resistivity | %43 IACS |

| Thermal Expansion | 23.4 x 10^-6 /K |

Aluminium Coils Weight Chart

Refer Aluminium Perforated Sheet Dimensions And Aluminium Roofing Sheet Weight Chart, Looking to buy Perforated Aluminium Sheet? contact Suryadeep Industry, A Reliable ASME SB209 Aluminium Cold Rolled Sheet Plate Distributor in India

Width: 1.000 mm | Length: 2.000 mm

| Thickness(milimeter) | Weight |

|---|---|

| 0,30 | 0,810 Kg/m2 |

| 0,40 | 1,080 Kg/m2 |

| 0,50 | 1,350 Kg/m2 |

| 0,60 | 1,620 Kg/m2 |

| 0,70 | 1,890 Kg/m2 |

| 0,80 | 2,160 Kg/m2 |

| 0,90 | 2,430 Kg/m2 |

| 1,00 | 2,700 Kg/m2 |

| 1,20 | 3,240 Kg/m2 |

| 1,40 | 3,780 Kg/m2 |

| 1,50 | 4,050 Kg/m2 |

| 1,60 | 4,320 Kg/m2 |

| 1,80 | 4,860 Kg/m2 |

| 2,00 | 5,400 Kg/m2 |

| 2,20 | 5,940 Kg/m2 |

| 2,50 | 6,750 Kg/m2 |

| 3,00 | 8,100 Kg/m2 |

| 4,00 | 10,800 Kg/m2 |

| 5,00 | 13,500 Kg/m2 |

| 6,00 | 16,200 Kg/m2 |

| 10,00 | 27,000 Kg/m2 |

| 12,00 | 32,400 Kg/m2 |

| 15,00 | 40,500 Kg/m2 |

| 20,00 | 54,000 Kg/m2 |