Buy Aluminium 5052 Plate, 5052-H32 Aluminum Alloy Sheets Best Price & Fast Delivery

Aluminium 5052 Sheet is a magnesium chromium alloy of aluminum that contains 2.5% magnesium and 0.25% chromium in the chemical composition. Suryadeep Industry is a leading supplier and distributor of the 5052 Sheet in different tempers, forms and finishes. The material has good weldability, good corrosion resistance and good fatigue strength. The 5052 Aluminum Sheet possesses excellent thermal conductivity and electric conductivity as well. The 5052 H32 Aluminum Sheet has silicon, iron, copper, manganese, zinc and other elements in trace amounts in the composition as well. The ASTM 5025 aluminum sheet has varying tensile and yield strength properties. The H38 tempered sheet has the most tensile strength of 270MPa minimum.The O tempered annealed 5052-H32 Aluminum Sheet has the least tensile strength ranging from 170MPa to 215MPa. Some sheets of this grade are suitable for pressure vessel applications under 200 degrees Celsius.

The 5052-H32 Aluminum Alloy Sheets are non – heat treatable alloys and they have resistance to alkaline products. The material has higher resistance to marine environments. This makes the Grade 5052 Aluminum Sheet applied mostly in marine environmental applications such as small boats. The material gets the high corrosion resistance by forming an oxide layer on the surface. When the Alloy 5052 Plate is exposed to oxygen, the reaction between aluminum and oxygen is rapid and the oxide layer forms. If scratched or damaged, the 5052-H32 Sheets immediately react to atmospheric oxygen and self-heal quickly. If you want to know more about the 5052 Aluminium Alloy Plate please contact us.

Table of Content - Aluminium 5052 Plate Material Standards And Grades - ASTM 5025 Aluminum Sheet Chemical Composition Table - 5052-H32 Aluminum Sheet Physical Property - Grade 5052 Aluminum Sheet Mechanical Properties Database - Common Types Of Aluminium 5052 Sheet - Equivalent Grades Of Aluminium 5052 Sheet - 5052-H32 Sheets Weigth Chart

Aluminium 5052 Plate Material Standards And Grades

| Standards | ASTM B209 / ASME SB209 |

|---|---|

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. |

| Temper | O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851 |

| Finish | Mill, Customer specific finish |

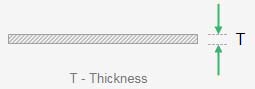

| Thickness | 0.2~300mm |

| Width | 500~2500mm |

| Type | Hot-Rolled (HR) / Cold-Rolled (CR) Sheet / Plates/ Strips/ Coils/ Chequered Plates |

| Aluminum Sheet/ Plate Coating | PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating |

| Length | 500~10000mm |

Buy Aluminium 5052 Plate At Best Price In Bhopal, India, Specification Of 5052 Sheet

ASTM 5025 Aluminum Sheet Chemical Composition Table

| Alloy (ISS) | Equivalent alloy (A.A) | Copper | Magnesium | Silicon | Iron | Others* (Total) | Remarks | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Old | New | U.S.A | Max. | Min. | Max. | Min. | Min. | Max. | Max. | Min. | Max | Max. | Aluminum 99.0% Min. | |

| N 4 | 52000 | 5052 | 0.1 | — | 2.6 | 1.7 | — | 0.6 | — | 0.5 | 0.5 | 0.4 | Cr+Mn=0.5 | |

5052-H32 Aluminum Sheet Physical Property

5052 Aluminum Sheet Physical Property, Check 5052 H32 Aluminum Sheet Chemical Composition, ASTM 5025 Aluminum Sheet Mechanical properties, Call Now to Get 5052-H32 Aluminum Sheet Free sample.

| Physical Property | Value |

|---|---|

| Thermal Expansion | 23.7 x10^-6 /K |

| Density | 2.68 g/cm³ |

| Thermal Conductivity | 138 W/m.K |

| Melting Point | 605 °C |

| Electrical Resistivity | 0.0495 x10^-6 Ω .m |

| Modulus of Elasticity | 70 GPa |

Grade 5052 Aluminum Sheet Mechanical Properties Database

| Mechanical Property | Value |

|---|---|

| Proof Stress | 130 Min MPa |

| Tensile Strength | 210 - 260 MPa |

| Hardness Brinell | 61 HB |

Common Types Of Aluminium 5052 Sheet

We provide 5052-H32 Aluminum Alloy Sheets Expert Service In Bhopal, Get Grade 5052 Aluminum Sheet At Best Price, India, Get a Live Quote Now For Alloy 5052 Plate.

Aluminium 5052 Plate

Aluminium 5052 Plate

5052 Sheet

5052 Sheet

5052 Aluminum Sheet

5052 Aluminum Sheet

5052 H32 Aluminum Sheet

5052 H32 Aluminum Sheet

ASTM 5025 Aluminum Sheet

ASTM 5025 Aluminum Sheet

5052-H32 Aluminum Sheet

5052-H32 Aluminum Sheet

5052-H32 Aluminum Alloy Sheets

5052-H32 Aluminum Alloy Sheets

Grade 5052 Aluminum Sheet

Grade 5052 Aluminum Sheet

Alloy 5052 Plate

Alloy 5052 Plate

5052-H32 Sheets

5052-H32 Sheets

5052 Aluminium Alloy Plate

5052 Aluminium Alloy Plate

Aluminium 5052 Sheet

Aluminium 5052 Sheet

Equivalent Grades Of Aluminium 5052 Sheet

Supplier Of 5052-H32 Sheets In Bhopal, India, Get Free Quote For 5052 Aluminium Alloy Plate, Equivalent Grades Of Aluminium 5052 Sheet.

| INDIA |

GERMANY |

U.S.A. |

RUSSIA |

BRITAIN |

I.S.O. |

CANADA | FRENCH | |

|---|---|---|---|---|---|---|---|---|

| New IS | Old IS | (DIN) | (A.A.) |

– | (B.S.) |

– | – | |

| 52000 | N4 | Al-Mg.2 | 5052 | A-Mg | N4 | A-Mg-4 | M57S | – |

5052-H32 Sheets Weigth Chart

Width: 1.000 mm | Length: 2.000 mm

| Thickness(milimeter) | Weight |

|---|---|

| 0,30 | 0,810 Kg/m2 |

| 0,40 | 1,080 Kg/m2 |

| 0,50 | 1,350 Kg/m2 |

| 0,60 | 1,620 Kg/m2 |

| 0,70 | 1,890 Kg/m2 |

| 0,80 | 2,160 Kg/m2 |

| 0,90 | 2,430 Kg/m2 |

| 1,00 | 2,700 Kg/m2 |

| 1,20 | 3,240 Kg/m2 |

| 1,40 | 3,780 Kg/m2 |

| 1,50 | 4,050 Kg/m2 |

| 1,60 | 4,320 Kg/m2 |

| 1,80 | 4,860 Kg/m2 |

| 2,00 | 5,400 Kg/m2 |

| 2,20 | 5,940 Kg/m2 |

| 2,50 | 6,750 Kg/m2 |

| 3,00 | 8,100 Kg/m2 |

| 4,00 | 10,800 Kg/m2 |

| 5,00 | 13,500 Kg/m2 |

| 6,00 | 16,200 Kg/m2 |

| 10,00 | 27,000 Kg/m2 |

| 12,00 | 32,400 Kg/m2 |

| 15,00 | 40,500 Kg/m2 |

| 20,00 | 54,000 Kg/m2 |