Contact Us For Corrosion Resistance 400 Plates, Cold Drawn 400 Monel Alloy Sheet Instant Delivery.

Monel 400 Plates is made for applications in corrosive environments, especially in sea water and marine applications. The material is made up of a solid solution alloy and could be hardened by cold working. Suryadeep Industry is a manufacturer and supplier of these sheets and plates in different sizes, shapes and quantities. The Alloy 400 Plates can be welded with ease and can be machined to high precision. It is resistant to rapidly flowing brackish water which makes it suitable for sea water purification systems. The material is also very much corrosion resistant against non – oxidizing chloride solutions. It has acidic resistance against hydrochloric and hydrofluoric acids as well.

The Monel 400 Sheet has high strength and high hardness. The minimum yield strength ranges from 30-40ksi and the minimum tensile strength ranges from 70-80ksi. The HRB hardness values fall between 65 and 80 for these sheets. With these high mechanical properties, the ASME SB 127 UNS N04400 Coil and other types of the sheets and plates are used in marine engineering, chemical processing plants, gasoline tanks, freshwater tanks, hydrocarbon processing equipment and in crude petroleum stills. The de-aerating heaters, chlorinated solvents, industrial heat exchangers and boiler components also use the sheets. The ASTM B127 UNS N04400 Strips can be used to produce pipes and tubes of the same grade as well. To know more about the products and the pricing, please contact us.

Table of Content - Monel 400 Sheet Most Common Specification - 2.4360 Alloy 400 Sheet Sizes - Monel Alloy 400 Plate Dimensions - Monel ASTM B127 Strip Tape Thicknesses - ASTM B127 Monel 400 Sheet Stock List - Basic Types Of Monel 400 Plate - UNS N04400 Plate Weight Chart - Monel Alloy 400 Sheet Chemical Analysis - 2.4360 Strip Mechanical Behaviour - Alloy 400 2D Plate Equivalent Grades - Difference between Monel 400 Plate, Sheet, & Foil - ASTM B127 Monel 400 Sheet Uses - Monel N04400 Plate Features

Monel 400 Sheet Most Common Specification

| Grade | MONEL 400 - ALLOY 400 (66 Ni/34 Cu) - UNS N04400 |

|---|---|

| Type | Foils, Coils, Plate, Strip, Sheet, Flats, Clad Plate, Rolling Plate, Flat Shim, Plain Sheet, Rolling Sheet Rolls, Blank (Circle), ,Flat Sheet, Shim Sheet, soft annealed, descaled, sheared, annealed, Checker Plate, tread plate |

| Specification | ASTM B127 UNS N04400, ASME SB127, MSRR, BS, AMS 4544 sheet |

| Surface | BA, No.3, No.4, No.6, No.1, No. 2D, No. 2B, BA NO(8), No.7, 2B, 2D, Hot rolled plate (HR), Cold rolled sheet (CR), No.1 finish hot rolled ASTM B127 Alloy 400 Plate, SATIN (Met with Plastic Coated), 2B, 1D, No.4, 8K, BA, hairline, brush, satin, mirror etc. |

| Length | 0-12mm or as required |

| Thickness | 0.3 to 1200 mm or as required |

| Width | 0-2500mm or as required |

| Process | Hot/ Cold Rolled |

| ASTM B127 Alloy 400 Plate, Sheet and Strip | DIN 17750 (Plate, Strip and Sheet), QQ-N-281 (Plate, Sheet, Strip, Bar, Rod, Wire, and Forgings), BS3073NA13 (Strip), BS3072NA13 (Sheet and Plate), ASTM B 127, ASME SB 127 (Plate, Sheet, and Strip), SAE AMS 4544 (Sheet, Strip, and Plate) |

|---|---|

| Monel 400 Plate standards and approvals |

|

| Tolerances of width and thickness |

|

| UNS N04400 Plate Hardness | Half Hard, Soft, Spring Hard, Quarter Hard, Hard ASTM B127 Alloy 400 Sheet suppliers |

| Standard ASTM B127 Alloy 400 Plate & Sheet Sizes | 1000 x 2000 mm, 1220 x 2440 mm, 1500 x 3000 mm, 2000 x 2000 mm, 2000 x 4000 mm

|

| Availability of ASTM B127 Alloy 400 Foil sizes |

|

| Plasma profiles | As per customer's drawings |

| Profiling | To provide a full profiling service in India we use numerous profiling methods including:

|

| Value added services for ASTM B127 Alloy 400 Coil |

|

| Value added services for ASTM B127 Alloy 400 Plate | Waterjet cutting, Laser cutting, Bending and mechanical processing, Plasma cutting, welding, edge preparation, sawing and shearing. |

| Monel 400 Plate Origin | European Origin, Indian Origin, Japanese Origin |

| Manufacturer & exporter of |

|

| Test | SGS testing, UT, TUV etc |

| Packing of Monel 400 Plate | Bundles with waterproof cloth outside or plywood box |

| Why buy ASTM B127 Alloy 400 Plate from Metal Tube Industries? |

|

UNS N04400 Monel 400 Foil Density

| UNS N04400 Monel 400 Plate density |

|

Fastest Growing Supplier Of Monel 400 Hot Rolled Plate, Stockist In India, Get at discount of Monel Asme Sb 127 Plates, Uns N04400 Monel Sheets Manufacturer In India.

Grade Monel 400 Clad Plate Melting Range

| ASTM B127 Alloy 400 Plate melting range |

|

2.4360 Alloy 400 Sheet Sizes

| Stocked Sizes | |

|---|---|

| Size (in inches) | Size (in mm) |

| .125" | 3.18 |

| .134" | 3.40 |

| .156" | 3.96 |

| .187" | 4.75 |

| .250" | 6.35 |

| .312" | 7.92 |

| .375" | 9.53 |

| .500" | 12.7 |

| .600" | 15.9 |

| .750" | 19.1 |

| .875" | 22.2 |

| 1" | 25.4 |

| 1.125" | 28.6 |

| 1.250" | 31.8 |

| 1.500" | 38.1 |

| 1.750" | 44.5 |

| 2" | 50.8 |

| 2.500" | 63.5 |

| 3" | 76.2 |

Monel Alloy 400 Plate Dimensions

widths 1000/1220/1500 mm,

lengths 2000/2500/3000 mm.

| Plate Surface finish | Width (max in) | Gauge (in) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed Plate | 72* | 10–24 |

| 2D – Cold rolled, heat treated, pickled plate | 60 | 12–24 |

| BA Mexinox only | 48 | 18–28 |

| Polished plate (not brushed) | 60 | 11–24 |

| Temper rolled plate Mexinox only | 48 | 13–29 |

Monel N04400 Plate Metric Dimensions

Refer Monel 400 Plate Dimensions And Weight Chart, Looking to buy ASTM B127 Monel 400 Sheet? contact Suryadeep Industry., A Reliable Monel 400 Chequered Plates Manufacturer in India.

| Plate Surface finish | Width (max mm) | Thickness (mm) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed plate | 2032 | 0.25–8.0 |

| 2D – Cold rolled, heat treated, pickled plate | 1524 | 0.4–6.35 |

| 2E – Cold rolled, heat treated, mechanically descaled plate | 2032 | 0.4–8.0 |

| 2R – Cold rolled, bright annealed plate | 1524 | 0.25–3.5 |

| 2H – Work hardened plate | 1524 | 0.4–6.35 |

| Polished, brushed plate | 1524 | 0.5–4.0 |

Monel ASTM B127 Strip Tape Thicknesses

| 0.5 0.6 0.8 1.0 1.2 1.5 1.6 1.8 2.0 3.0 |

4.0 |

ASTM B127 Monel 400 Sheet Stock List

| Alloy | Product form | Dimension |

|---|---|---|

| 66 Ni/34 Cu | Sheet; cold rolled, annealed | 0.6x914x2440 mm, 11.5 kg/pc |

| 66Ni/34Cu | Sheet; cold rolled, annealed | 0.9x1220 mm x coil, 9.7 kg/m |

| 66Ni/34Cu | Sheet; cold rolled, annealed | 1.0x1000x2000 mm, 17.5 kg/pc |

| 66 Ni/34 Cu | Sheet; cold rolled, annealed | 1.6x1200x3000 mm, 50.7 kg/pc |

| 66 Ni/34 Cu | Sheet; cold rolled, pickled, annealed | 2.0x1200x3000 mm, 64 kg/pc |

| 66 Ni/34 Cu | Sheet; cold rolled, soft annealed, descaled, sheared | 3.0x1220x3000 mm, 97 kg/pc |

| 66 Ni/34 Cu | Plate; hot rolled, annealed | 4.0x2000x4000 mm, 281.5 kg/pc |

| 66 Ni/34 Cu | Plate; hot rolled, annealed, descaled | 5.0x2400x6000 mm, 640 kg/pc |

| 66 Ni/34 Cu | Plate; hot rolled, soft annealed, descaled | 12.0x1495x2000 mm, 309 kg/pc |

| 66 Ni/34 Cu | Plate; hot rolled, descaled, annealed | 20.0x1200x2000 mm, 413 kg/pc |

| GR2 PL 008,0 4000 x 1000 | plate | 8.0x1000x4000 mm, 144,3 kg/St. |

Basic Types Of Monel 400 Plate

We Maintain Monel 400 Alloy Polished Plate Good Quality, Monel 400 Perforated Sheets Suppliers In Bhopal, India, Check Availability Of Alloy 400 2D Plate, Get Free Quote Of Din 2.4360 Monel Shim Sheets.

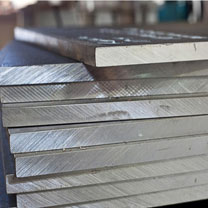

Cold Drawn 400 Monel Alloy Plates

Cold Drawn 400 Monel Alloy Plates

Monel 400 Hot Rolled Plates

Monel 400 Hot Rolled Plates

Uns N04400 Monel Sheets

Uns N04400 Monel Sheets

Monel 400 Plates

Monel 400 Plates

ASTM B127 Monel 400 Sheet

ASTM B127 Monel 400 Sheet

Monel 400 Chequered Plates

Monel 400 Chequered Plates

Monel 400 Alloy Polished Plates

Monel 400 Alloy Polished Plates

Monel 400 Perforated Sheets

Monel 400 Perforated Sheets

Alloy 400 2D Plates

Alloy 400 2D Plates

Din 2.4360 Monel Shim Sheets

Din 2.4360 Monel Shim Sheets

Monel Alloy 400 Plates

Monel Alloy 400 Plates

Monel Alloy 400 Sheet

Monel Alloy 400 Sheet

UNS N04400 Plate Weight Chart

| Thickness (inches) | Plate Weight per Unit Area | Density |

|---|---|---|

| 3/16 | 0.06000 lbs/in²42.184176 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/4 | 0.08 lbs/in²56.245568 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/8 | 0.121 lbs/in²85.0714216 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/2 | 0.161 lbs/in²113.1942056 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 5/8 | 0.196 lbs/in²137.8016416 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/4 | 0.235 lbs/in²165.221356 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 7/8 | 0.274 lbs/in²192.6410704 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 | 0.313 lbs/in²220.0607848 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/4 | 0.391 lbs/in²274.9002136 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/2 | 0.47 lbs/in²330.442712 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 3/4 | 0.549 lbs/in²385.9852104 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 | 0.627 lbs/in²440.8246392 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/4 | 0.705 lbs/in²495.664068 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/2 | 0.784 lbs/in²551.2065664 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 3/4 | 0.862 lbs/in²606.0459952 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3 | 0.941 lbs/in²661.5884936 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

Monel Alloy 400 Sheet Chemical Analysis

| Grade | S | C | Cu | Mn | Fe | Si | Ni |

|---|---|---|---|---|---|---|---|

| Monel 400 | 0.024 max | 0.30 max | 28.00 – 34.00 | 2.00 max | 2.50 max | 0.50 max | 63.00 min |

2.4360 Strip Mechanical Behaviour

Monel Alloy 400 Plate Size Range, Check Monel Alloy 400 Sheet Chemical Composition, Alloy 400 Monel 2.4360 Slitting Coil Mechanical properties, Call Now to Get Monel 400 Sheet Free sample.

| Element | Tensile Strength | Density | Yield Strength | Melting Point | Elongation |

|---|---|---|---|---|---|

| Monel 400 | Psi – 80,000 , MPa – 550 | 8.8 g/cm3 | Psi – 35,000 , MPa – 240 | 1350 °C (2460 °F) | 40 % |

Alloy 400 2D Plate Equivalent Grades

| STANDARD | BS | WERKSTOFF NR. | GOST | UNS | AFNOR | JIS | EN |

|---|---|---|---|---|---|---|---|

| Monel 400 | NA 13 | 2.4360 | МНЖМц 28-2,5-1,5 | N04400 | NU-30M | NW 4400 | NiCu30Fe |

Difference between Monel 400 Plate, Sheet, & Foil

- Thickness greater than 6.35 mm is called a Monel 400 Plate.

- Thickness greater than 0.15 mm and less than 6.35mm is called a Monel 400 Sheet.

- Thickness less than 0.15mm is called a Monel 400 Foil.

ASTM B127 Monel 400 Sheet Uses

- Nuclear waste reprocessing equipment

- Aerospace equipment

- Jet Engine exhaust systems

- Motor racing exhaust systems

- Chimney Linings

- Chemical Processing

- Sour gas production tubes

Monel N04400 Plate Features

- Excellent mechanical properties

- High strength and good weldability under a wide range of temperatures

- Non-magnetic

- Resistant to a wide range of corrosive media.

- Virtually immune to chlorine ion stress corrosion cracking