Get Free Quote Of UNS A92014 Sheet, 2014 Aluminium Alloy Plates.

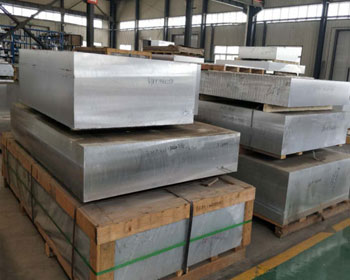

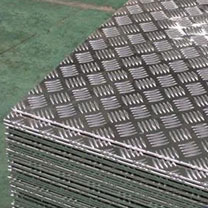

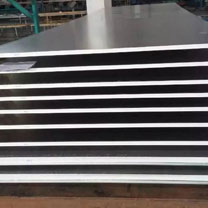

Aluminium 2014 Sheet is a high toughness sheet that retains the mechanical properties in reactive and non – reactive conditions. The ASTM B209 Aluminum Alloy 2014 Plates can be interchangeably used in different applications with multipurpose services. Suryadeep Industry is a leading distributor and supplier of the 2014 Aluminium Hot Rolled Plate and the cold plate types. There are different stages for the production and the sheets are forged rolled and formed as part of the manufacturing of Aluminium 2014 Chequered Plate and other finishes. The specification for the sheets is ASTM B209 and they range in dimensions. The 2014 Aluminium HR Plate and other ranges from 0.2mm to 300mm in thickness and 500mm to 2500mm in width and 500mm to 10000mm in length.

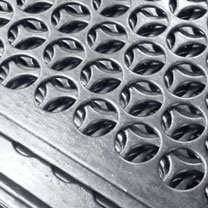

The Aluminium 2014 Coils and other forms of plates could be sold in cut to lengths as well. The material has different customer specific finishes but the mill finish is the standard finish for the ASME SB209 Aluminium 2014 Sheets. There are HR, CR, plate, strip, coil and checkered plates. The aluminum sheet processing includes hot rolling, cold rolling, cutting, grinding, polishing and drilling of the Aluminium 2014 Perforated Sheets and other types. The Alloy 2014 Perforated Sheet reduces the weight per area of the already lightweight aluminum material. The sheets are used in aerospace and chemical industries. The airplane parts are made with the Aluminium Alloy 2014 Flat Sheet to greatly reduce the weight of the planes. The yield strength is mild with 230MPa and the tensile strength is minimum 370MPa. Please contact us for your needs of the Alloy 2014 Chequered Plate and other types of these plates and their prices.

Table of Content - 2014 Aluminium HR Plate Sizes And Schedule Specifications - Aluminium 2014 Plate Chemical Analysis - UNS A92014 Plate Mechanical Characteristics - 2014 Aluminium Alloy Plates Equivalent Grades - Basic Types Of Aluminium 2014 Sheet - Aluminium 2014 T6 Sheet Physical Properties - Aluminium 2014 Coils Weight Chart

2014 Aluminium HR Plate Sizes And Schedule Specifications

| Standards | ASTM B209 / ASME SB209 |

|---|---|

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. |

| Temper | O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851 |

| Finish | Mill, Customer specific finish |

| Thickness | 0.2~300mm |

| Width | 500~2500mm |

| Type | Hot-Rolled (HR) / Cold-Rolled (CR) Sheet / Plates/ Strips/ Coils/ Chequered Plates |

| Aluminum Sheet/ Plate Coating | PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating |

| Length | 500~10000mm |

Specifications Of ASTM B209 Aluminum Alloy 2014 Plates, Distributor Of 2014 Aluminium Hot Rolled Plate, Check the Market price before you buy Aluminium 2014 Chequered Plate In India.

Aluminium 2014 Plate Chemical Analysis

| Alloy | Ti | Si | Other | Fe | Ni | Cu | Others | Zn | Cr | Mn | Ti+Zr | Mg | Al |

| 2014 | 0.0 - 0.15 | 0.50 - 0.90 | 0.0 - 0.15 | 0.0 - 0.50 | 0.0 - 0.10 | 3.90 - 5.00 | 0.0 - 0.05 | 0.0 - 0.25 | 0.0 - 0.10 | 0.40 - 1.20 | 0.0 - 0.20 | 0.20 - 0.80 | Balance |

UNS A92014 Plate Mechanical Characteristics

Chemical And Mechanical Composition Of 2014 Aluminium HR Plate, Aluminum 2014 Cold Rolled Sheet Stockist In India, Check Our Global Sales Network For Aluminium 2014 Coils.

| Alloy | Temper | UTS (Mpa) | Yield Strength (Mpa) | Elongation (%) | ||

| - | Minimum | - | Maximum | Minimum | Maximum | A 50mm (Minimum) |

| EN AW-2014 | – | O | 250 | – | 135 | 10 |

| 370 | T4 | – | 230 | – | 11 | |

2014 Aluminium Alloy Plates Equivalent Grades

| UNS | European Standard | USA (AA) | IS | BS (OLD) | GERMANY (DIN) | WNr | Canadian | ISO |

| A92014 | EN AW-2014 | 2014 | 24345 | HE15 | AlCuSiMn | 3.1255 | B26S | AlCu4SiMg |

Basic Types Of Aluminium 2014 Sheet

Get instant delivery of Aluminium 2014 Plate In India, ASME SB209 Aluminium 2014 Sheets Various Types, Best price on bulk Aluminium 2014 Perforated Sheets, Aluminium 2014 Sheet Stock.

ASTM B209 Aluminum Alloy 2014 Plates

ASTM B209 Aluminum Alloy 2014 Plates

2014 Aluminium Hot Rolled Plate

2014 Aluminium Hot Rolled Plate

UNS A92014 Plate

UNS A92014 Plate

Aluminium 2014 Chequered Plate

Aluminium 2014 Chequered Plate

2014 Aluminium HR Plate

2014 Aluminium HR Plate

Aluminum 2014 Cold Rolled Sheet

Aluminum 2014 Cold Rolled Sheet

Aluminium 2014 Coils

Aluminium 2014 Coils

ASME SB209 Aluminium 2014 Sheets

ASME SB209 Aluminium 2014 Sheets

Aluminium 2014 Perforated Sheets

Aluminium 2014 Perforated Sheets

Alloy 2014 Perforated Sheet

Alloy 2014 Perforated Sheet

Aluminium Alloy 2014 Flat Sheet

Aluminium Alloy 2014 Flat Sheet

Alloy 2014 Chequered Plate

Alloy 2014 Chequered Plate

Aluminium 2014 T6 Sheet Physical Properties

Check Also Alloy 2014 Perforated Sheet Weight Chart And Aluminium Alloy 2014 Flat Sheet Physical Properties, Thickness Of Alloy 2014 Chequered Plate, Werkstoff-Nr. 3.1255 Sheet.

| Physical Property | Value |

|---|---|

| Thermal Conductivity | 138 W/m.K |

| Density | 2.82 g/cm³ |

| Thermal Expansion | 23 x10^-6 /K |

| Modulus of Elasticity | 71 GPa |

| Melting Point | 535 °C |

| Electrical Resistivity | 0.045 x10^-6 Ω .m |

Aluminium 2014 Coils Weight Chart

Width: 1.000 mm | Length: 2.000 mm

| Thickness(milimeter) | Weight |

|---|---|

| 0,30 | 0,810 Kg/m2 |

| 0,40 | 1,080 Kg/m2 |

| 0,50 | 1,350 Kg/m2 |

| 0,60 | 1,620 Kg/m2 |

| 0,70 | 1,890 Kg/m2 |

| 0,80 | 2,160 Kg/m2 |

| 0,90 | 2,430 Kg/m2 |

| 1,00 | 2,700 Kg/m2 |

| 1,20 | 3,240 Kg/m2 |

| 1,40 | 3,780 Kg/m2 |

| 1,50 | 4,050 Kg/m2 |

| 1,60 | 4,320 Kg/m2 |

| 1,80 | 4,860 Kg/m2 |

| 2,00 | 5,400 Kg/m2 |

| 2,20 | 5,940 Kg/m2 |

| 2,50 | 6,750 Kg/m2 |

| 3,00 | 8,100 Kg/m2 |

| 4,00 | 10,800 Kg/m2 |

| 5,00 | 13,500 Kg/m2 |

| 6,00 | 16,200 Kg/m2 |

| 10,00 | 27,000 Kg/m2 |

| 12,00 | 32,400 Kg/m2 |

| 15,00 | 40,500 Kg/m2 |

| 20,00 | 54,000 Kg/m2 |