Get Free Quote Of Aluminium Alloy 5005 Plates, ASME SB209 Aluminium 5005 Plain Sheet.

Aluminium 5005 Sheet is made up of a material composition of aluminum, manganese, silicon, iron, copper, manganese, chromium, zinc and other trace elements. Suryadeep Industry is a leading supplier and distributor of the Aluminum 5005 Sheet in different forms, finishes and tempers. There are annealed O temper sheets and the H series temper sheets. The Aluminium 5005 H14 Sheet material ranges in tensile and yield strength together with elongation depending on the temper of the plates. the H38 tempered ASME SB209 Aluminium 5005 Plain Sheet has the most tensile strength with minimum 180MPa and the lower tempers have lower strength values. The Aluminium A95005 Sheet has a melting range of 632MPa to 655MPa.The sheets belong to the B209 specification. The grading of the Aluminium Alloy 5005 Sheets is UNS A95005. The material becomes stronger with increased tensile strength at subzero temperatures.

The 5005 H32 Aluminum Sheet is made up of a non – heat treatable alloy that has excellent corrosion resistance to atmospheric agents. Despite being in aluminum, the Aluminium 5005 H24 Sheets and other variations are weldable. This is a commercially pure grade of aluminum with 99.2% aluminum. The material also has good electric conductivity. The Aluminium 3.3315 Sheets are resistant to temperature deviations. The applications of the material includes appliances, utensils, gas lines and in refrigerator panels. The Aluminum 5005 H26 Sheet is also used in making small size boats because of their corrosion resistance and lightweight nature. However the material can brittle under high impact stress. Please contact us for more information and 5005 Aluminium Sheets prices.

Table of Content - Aluminum 5005 Plate Size Standard And Specification - Aluminium A95005 Sheet Chemical Compatibility Chart - 5005 H32 Aluminum Sheet Mechanical Properties Database - Equivalent Material Of 5005 Aluminium Sheets - Basic Types Of Aluminium 5005 Sheet - ASME SB209 Aluminium 5005 Plain Sheet Weight Chart

Aluminum 5005 Plate Size Standard And Specification

| Standards | ASTM B209 / ASME SB209 |

|---|---|

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. |

| Temper | O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851 |

| Finish | Mill, Customer specific finish |

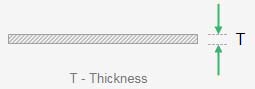

| Thickness | 0.2~300mm |

| Width | 500~2500mm |

| Type | Hot-Rolled (HR) / Cold-Rolled (CR) Sheet / Plates/ Strips/ Coils/ Chequered Plates |

| Aluminum Sheet/ Plate Coating | PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating |

| Length | 500~10000mm |

Standards Range Of Aluminum 5005 Plate, Buy Aluminium 5005 H14 Sheet At Low Price, Aluminium A95005 Sheet Specification.

Aluminium A95005 Sheet Chemical Compatibility Chart

| Element | % | Element | % |

| Aluminium | Balance | Manganese | 0.20 max |

| Iron | 0.07 max | Others, each | 0.05 max |

| Magnesium | 0.50 – 1.10 | Chromium | 0.10 max |

| Copper | 0.20 max | Others, total | 0.15 max |

| Silicon | 0.30max | Zinc | 0.25 max |

5005 H32 Aluminum Sheet Mechanical Properties Database

Refer Aluminium Alloy 5005 Sheets Chemical Requirements, Aluminium 5005 HR Plates Mechanical Requirements, Best offer on bulk 5005 H32 Aluminum Sheet stock.

| Temper | Tensile Strength, MPa | 0.2% Proof Stress, MPa min† | Elongation % min‡ |

| O (annealed) | 105 – 145 | 35 | 12 – 22 |

| H12 | 125 – 165 | 95 | 2 – 8 |

| H14 | 145 – 185 | 115 | 1 – 6 |

| H16 | 165 – 205 | 135 | 1 – 3 |

| H18 | > 185 | – | 1 – 3 |

| H32 | 115 – 160 | 85 | 3 – 9 |

| H34 | 135 – 180 | 105 | 2 – 7 |

| H36 | 160 – 200 | 125 | 1 – 4 |

| H38 | > 180 | – | 1 – 4 |

Equivalent Material Of 5005 Aluminium Sheets

Buy Aluminium 5005 H24 Sheets, Aluminium 5005 Sheet Best Price & Fast Delivery, Aluminium 5005 Hot Rolled Plates Equivalent, Distributor Of Aluminium 3.3315 Sheets In India.

| Standard | BS | UNS | DIN | ISO |

| 5005 | N41 | A95005 | 3.3315 | AlMg1 |

Basic Types Of Aluminium 5005 Sheet

Aluminium 5005 H14 Sheet

Aluminium 5005 H14 Sheet

ASME SB209 Aluminium 5005 Plain Sheet

ASME SB209 Aluminium 5005 Plain Sheet

Aluminium A95005 Sheet

Aluminium A95005 Sheet

Aluminium Alloy 5005 Sheets

Aluminium Alloy 5005 Sheets

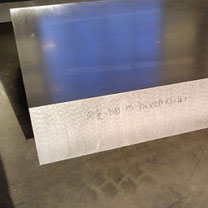

Aluminium 5005 HR Plates

Aluminium 5005 HR Plates

5005 H32 Aluminum Sheet

5005 H32 Aluminum Sheet

Aluminium 5005 H24 Sheets

Aluminium 5005 H24 Sheets

Aluminium 5005 Hot Rolled Plates

Aluminium 5005 Hot Rolled Plates

Aluminium 3.3315 Sheets

Aluminium 3.3315 Sheets

Aluminium 5005 Cold Forming Plates

Aluminium 5005 Cold Forming Plates

Aluminum 5005 H26 Sheet

Aluminum 5005 H26 Sheet

5005 Aluminium Sheets

5005 Aluminium Sheets

ASME SB209 Aluminium 5005 Plain Sheet Weight Chart

Refer Aluminium 5005 Cold Forming Plates Types And Weight Chart, Looking to buy Aluminum 5005 H26 Sheet? contact Suryadeep Industry, A Reliable 5005 Aluminium Sheets Distributor in India

Width: 1.000 mm | Length: 2.000 mm

| Thickness(milimeter) | Weight |

|---|---|

| 0,30 | 0,810 Kg/m2 |

| 0,40 | 1,080 Kg/m2 |

| 0,50 | 1,350 Kg/m2 |

| 0,60 | 1,620 Kg/m2 |

| 0,70 | 1,890 Kg/m2 |

| 0,80 | 2,160 Kg/m2 |

| 0,90 | 2,430 Kg/m2 |

| 1,00 | 2,700 Kg/m2 |

| 1,20 | 3,240 Kg/m2 |

| 1,40 | 3,780 Kg/m2 |

| 1,50 | 4,050 Kg/m2 |

| 1,60 | 4,320 Kg/m2 |

| 1,80 | 4,860 Kg/m2 |

| 2,00 | 5,400 Kg/m2 |

| 2,20 | 5,940 Kg/m2 |

| 2,50 | 6,750 Kg/m2 |

| 3,00 | 8,100 Kg/m2 |

| 4,00 | 10,800 Kg/m2 |

| 5,00 | 13,500 Kg/m2 |

| 6,00 | 16,200 Kg/m2 |

| 10,00 | 27,000 Kg/m2 |

| 12,00 | 32,400 Kg/m2 |

| 15,00 | 40,500 Kg/m2 |

| 20,00 | 54,000 Kg/m2 |