Get 7075 Aluminium Plates, ASTM B209 Aluminum Alloy 7075 Sheet Free sample

Aluminium 7075 Sheet has zinc in the composition. The primary alloying element makes it good ductility, high strength and good fatigue resistant 7075 Aluminium Plates. The toughness and high mechanical properties of the plates make them applicable in various industrial applications. The 7075 Aluminium Hot Rolled Plate is also strong with 572MPa minimum tensile strength and 87HRB Rockwell hardness scale. The elongation of the ASTM B209 Aluminum Alloy 7075 Plates is at 11% and the density is very low. The 2.81grams per centimeter cube density makes the material very light. With the Aluminium 7075 Chequered Plate having very less weight with corrosion resistance and strength is the primary reason for usage in aerospace applications.

The Aluminium Plate 7075 has high thermal conductivity and high electric conductivity as well. However, the material is susceptible to ebrittlement. ASME SB209 Aluminium 7075 Sheets are mostly used in aerospace applications. The material also comes in different forms such as the coils and strips. The Aluminium 7075 Coils are heat resistant and can be used in high heat applications. The Aluminium 7075 Perforated Sheets is one of the types of finishes available in the plates. The perforated sheets and plates are even lighter in weight. The 7075 Aluminium HR Plate as well as other types of plates belongs to the ASTM B209 specifications. Please contact us for further information and pricing of the Aluminium 7075 Plate products.

Table of Content - 7075 Aluminium Plates Specification And Grade - Aluminium 7075 Coils Chemical Analysis - Alloy UNS A97075 Sheets Mechanical Characteristics - Equivalent Of Aluminium DIN 3.4365 Sheets - Most Frequent Types Of Aluminium 7075 Sheet - ASTM B209 Aluminum Alloy 7075 Plates Weight Chart

7075 Aluminium Plates Specification And Grade

| Standards | ASTM B209 / ASME SB209 |

|---|---|

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. |

| Temper | O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851 |

| Finish | Mill, Customer specific finish |

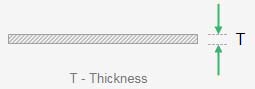

| Thickness | 0.2~300mm |

| Width | 500~2500mm |

| Type | Hot-Rolled (HR) / Cold-Rolled (CR) Sheet / Plates/ Strips/ Coils/ Chequered Plates |

| Aluminum Sheet/ Plate Coating | PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating |

| Length | 500~10000mm |

Buy Aluminium 7075 Chequered Plate, Aluminium Plate 7075 At Best Price In Bhopal, India, Specification Of ASME SB209 Aluminium 7075 Sheets

Aluminium 7075 Coils Chemical Analysis

| Weight % | Cr | Si | Zn | Fe | Ti | Cu | Each | Mn | Total | Mg |

| Minimum | 0.18 | 5.10 | 1.20 | 2.10 | ||||||

| Maximum | 0.28 | 0.40 | 6.10 | 0.50 | 0.20 | 2.00 | 0.05 | 0.30 | 0.15 | 2.90 |

Alloy UNS A97075 Sheets Mechanical Characteristics

Check Aluminium 7075 Coils Chemical Composition And Aluminium DIN 3.4365 Sheets Mechanical Properties. Get 7075 Aluminium Hot Rolled Plate With Best Price & Fast Delivery.

| Temper | Tensile | Hardness | ||||

| Ultimate | Yield | Elongation | Brinell | |||

| MPA | KSI | KSI | MPA | % | ||

| T6, T651 | 572 | 83 | 73 | 503 | 11 | 150 |

| T73, T7351 | 503 | 73 | 63 | 434 | 13 | N/A |

Equivalent Of Aluminium DIN 3.4365 Sheets

Accept all small/ Large Orders Aluminum 7075 Cold Rolled Sheet, Availability Of Aluminium 7075 Perforated Sheets, View Aluminium Alloy 7075-t6 Sheets, Aluminium 7075 Sheet Grades Equivalent.

| JIS | UNS | AFNOR | EN | ISO | DIN,WNr | BS | GOST |

| 7075 | A97075 | 7075 A-Z5GU | ENAW-AlZn5.5MgCu EN AW-7075 |

AlZn6MgCu | 3.4365 AlZnMgCu1.5 |

7075 L95 L96 | V95 |

Most Frequent Types Of Aluminium 7075 Sheet

7075 Aluminium Hot Rolled Plate

7075 Aluminium Hot Rolled Plate

ASTM B209 Aluminum Alloy 7075 Plates

ASTM B209 Aluminum Alloy 7075 Plates

Aluminium 7075 Chequered Plate

Aluminium 7075 Chequered Plate

Aluminium Plate 7075

Aluminium Plate 7075

ASME SB209 Aluminium 7075 Sheets

ASME SB209 Aluminium 7075 Sheets

Aluminium 7075 Coils

Aluminium 7075 Coils

Aluminium DIN 3.4365 Sheets

Aluminium DIN 3.4365 Sheets

Aluminum 7075 Cold Rolled Sheet

Aluminum 7075 Cold Rolled Sheet

Aluminium 7075 Perforated Sheets

Aluminium 7075 Perforated Sheets

Aluminium Alloy 7075-t6 Sheets

Aluminium Alloy 7075-t6 Sheets

7075 Aluminium HR Plate

7075 Aluminium HR Plate

Aluminium 7075 Plate

Aluminium 7075 Plate

ASTM B209 Aluminum Alloy 7075 Plates Weight Chart

Check Attractive Price Offer On 7075 Aluminium HR Plate In India, Aluminium 7075 Plate Various Types, 7075 Aluminium Alloy Plates, Aluminium Alloy UNS A97075 Sheets Weight Chart.

Width: 1.000 mm | Length: 2.000 mm

| Thickness(milimeter) | Weight |

|---|---|

| 0,30 | 0,810 Kg/m2 |

| 0,40 | 1,080 Kg/m2 |

| 0,50 | 1,350 Kg/m2 |

| 0,60 | 1,620 Kg/m2 |

| 0,70 | 1,890 Kg/m2 |

| 0,80 | 2,160 Kg/m2 |

| 0,90 | 2,430 Kg/m2 |

| 1,00 | 2,700 Kg/m2 |

| 1,20 | 3,240 Kg/m2 |

| 1,40 | 3,780 Kg/m2 |

| 1,50 | 4,050 Kg/m2 |

| 1,60 | 4,320 Kg/m2 |

| 1,80 | 4,860 Kg/m2 |

| 2,00 | 5,400 Kg/m2 |

| 2,20 | 5,940 Kg/m2 |

| 2,50 | 6,750 Kg/m2 |

| 3,00 | 8,100 Kg/m2 |

| 4,00 | 10,800 Kg/m2 |

| 5,00 | 13,500 Kg/m2 |

| 6,00 | 16,200 Kg/m2 |

| 10,00 | 27,000 Kg/m2 |

| 12,00 | 32,400 Kg/m2 |

| 15,00 | 40,500 Kg/m2 |

| 20,00 | 54,000 Kg/m2 |