Supplier of ASME SA387 Plate and Alloy Steel Foils

Alloy Steel Plate Suppliers is a metallic plate that is made up of steels with alloying elements. There are different elements that are used to make the alloys. Suryadeep Industry is a distributor of different alloy steels plates. The Alloy Steel Sheet materials range with the alloying elements. The commonly used alloying elements are chromium, nickel, aluminum, boron, cobalt, columbium, molybdenum, titanium, tungsten, vanadium and zirconium. The Alloy Steel Coil is a type of product that is used mostly in temperature specific applications based on the thermal conductivities of the material grades. There are Chrome Moly Pressure Vessel Plates that are made up of a chromium molybdenum alloy. There are different specifications of the Alloy Steels Plate chromium molybdenum alloys that differ in composition.

The ASTM A387 Alloy Steel Cold Drown Plates are a specified set of pressure vessels. These are intended for high temperature services. The high temperature resistant plates are used in welded boilers and pressure vessels. The Alloy Steel ASME SA387 Plates are also strong. They have minimum tensile strength of 515-690MPa depending on the material grade and composition. The yield strength is about 310MPa. There Alloy Cr-Mo Steel Plate is corrosion resistant to most corrosive media including chloride ion rich environments. They are also resistant to pitting and crevice attacks. The Alloy Steels ASTM A387 Plates are used in making storage tanks and containers in corrosive applications like the desalination plants, petroleum processing, pharmaceuticals and in food processing. Please contact us for any type of Alloy Steels Sheets in India such as the 4140 Alloy Steel Plate and their prices.

Table of Content - Alloy Steel Circle Standards And Specifications - Alloy Steel Hot Rolled Plates Chemical Structure - Mechanical Behaviour for Alloy Steel Foils - ASTM A387 Alloy Sheet Types - SA387 Alloy Steel Plates Comparable Plate, Pipe and Forging - Alloy Steel Strips Thickness Chart - Technical of ASME SA 387 Alloy Steel Plates - Alloy Steel Cold Rolled Plates Grade List - Price of Alloy Steel Plate Suppliers in India - Temperature Limit of Alloy Steel Sheet - High Nickel Alloys Plates Tensile and Yield Strength - Alloy Steel Foils HS code - ASTM A387 Alloy Steel PlateS Weight Chart - Alloy Steel Sheet Laser Cutting - Chrome Molybdenum Alloy Steel PlateS Uses and Applications - ASME SA 387 Alloy Steel Structural Plate Welding Material

Alloy Steel Circle Standards And Specifications

| Specifications | ASME SA387 / ASTM A387 |

| Surface | 2D, 2B, BA, NO.4, NO.1, NO.8, mirror, 8K, checkered, hair line, embossed, sand Brush, blast, etching |

| Thickness | From 1 milimeter to 300 milimeter |

| Length | 2440 milimeter, 2000 milimeter, 3000 milimeter, 6000 milimeter, 5800 milimeter, 15000 milimeter, 12000 milimeter |

| Width |

1219milimeter, 1000 milimeter, 1500 milimeter, 2000 milimeter, 1800 milimeter, 2500 milimeter, 3500 milimeter, 3000 milimeter, 4050 milimeter |

| Form | Foils, Plain Sheet, Coils, Strip, Rolls, Shim Sheet etc. |

| Finish | Cold rolled sheet, Hot rolled plate |

Check latest Alloy Steel Coils at best price, Contact us to get the Alloy Steel Hot Rolled Plates and Alloy Steel Foils detailed price list.

Alloy Steel Hot Rolled Plates Chemical Structure

| S | C | SI | Mn | Cr | P | Mo | |

| AS Grade 5 Plate | 0.03 | 0.15 max | 0.5 max | 0.3 – 0.6 | 4.00 – 6.00 | 0.035 | 0.45 – 0.65 |

| AS Grade 9 Plate | 0.03 | 0.15 max | 1.0 max | 0.30 – 0.6 | 8.0 – 10.0 | 0.03 | 0.9 – 1.1 |

| AS Grade 11 Plate | 0.035 | 0.05 – 0.17 | 0.5 – 0.80 | 0.4 – 0.65 | 1.0 – 1.5 | 0.035 | 0.45 – 0.65 |

| AS Grade 12 Plate | 0.035 | 0.05 – 0.17 | 0.15 – 0.4 | 0.4 – 0.65 | 0.8 – 1.15 | 0.035 | 0.45 – 0.6 |

| AS Grade 22 Plate | 0.035 | 0.05 – 0.15 | 0.5 max | 0.3 – 0.6 | 2.0 – 2.5 | 0.035 | 0.9 – 1.1 |

Mechanical Behaviour for Alloy Steel Foils

| Tensile Properties | Tensile Properties | Yield Properties | Elongational | Yield Properties | ||

| AS Gr 5 Plate | Cl1 | 415-585 | 60-85 | 205 | 18 | 30 |

| Cl2 | 515-690 | 75-100 | 310 | 18 | 45 | |

| AS Gr 9 Plate | Cl1 | 415-585 | 60-85 | 205 | 18 | 30 |

| Cl2 | 515-690 | 75-100 | 310 | 18 | 45 | |

| AS Gr 11 Plate | Cl1 | 415-585 | 60-85 | 240 | 22 | 35 |

| Cl2 | 485-620 | 70-90 | 310 | 22 | 45 | |

| AS Gr 12 Plate | Cl1 | 380-550 | 50-80 | 230 | 22 | 33 |

| Cl2 | 450-585 | 65-85 | 275 | 22 | 40 | |

| AS Gr 22 Plate | Cl1 | 415-585 | 60-85 | 205 | 18 | 30 |

| Cl2 | 515-690 | 75-100 | 310 | 18 | 45 | |

ASTM A387 Alloy Sheet Types

We are a specialist Alloy Steel Sheet distributors In India of high-quality ASME SA 387 Alloy Steels Plates, Call us for a free sample of Chrome Molybdenum Alloy Steel Plate, SA387 Alloy Steels Plates Stockist In Bhopal.

Alloy Steel Circle

Alloy Steel Circle

Alloy Steel Coils

Alloy Steel Coils

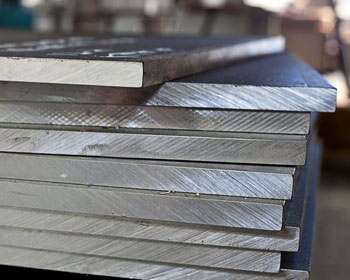

Alloy Steel Hot Rolled Plates

Alloy Steel Hot Rolled Plates

Alloy Steel Cold Rolled Plates

Alloy Steel Cold Rolled Plates

Chrome Molybdenum Strips

Chrome Molybdenum Strips

Alloy Steel Foils

Alloy Steel Foils

SA387 Alloy Steel Plates Comparable Plate, Pipe and Forging

| Forging/Flange Grade A182 | Plate Grade | Pipes Grade ASTM A335 |

| F22 | ASTM A387-22-2 | P22 |

| F1 | BSEN10028-2 16M03 | P1 |

| F11-2 | ASTM A387-11-2 | P11 |

| F12-2 | ASTM A387-12-2 | P12 |

| F5 | ASTM A387-5-2 | P5 |

| F9 | ASTM A387-91-2 | P91 |

Alloy Steel Strips Thickness Chart

Chrome Molybdenum Polished Plate offers corrosion resistance & Alloy Steel Hot Rolled Plates, Alloy Steel Coils strength at good pricing and a wide range of shapes.

| Item Dimension thickness is in inches | ||

|---|---|---|

| 4" | 0.025" | 0.75" |

| 3.5" | 0.032" | 0.875" |

| 0.109" | 0.036" | 1" |

| 0.125" | 0.04" | 1.125" |

| 0.16" | 0.05" | 1.25" |

| 0.19" | 0.063" | 1.5" |

| 0.25" | 0.071" | 1.75" |

| 0.3125" | 0.08" | 2" |

| 0.375" | 0.09" | 2.5" |

| 0.5" | 0.095" | 3" |

| 0.625" | 0.1" | |

Technical of ASME SA 387 Alloy Steel Plates

| Grade |

P |

C |

Cr |

Min |

Ni | Si |

S |

Mo |

Cu |

| Gr 5 - Cl 2 | 0.035 | 0.15 | 4.0 6.0 |

0.30 0.60 |

--- | 0.50 | 0.035 | 0.45 0.65 |

--- |

| Gr 11 - CI 2 | 0.035 | 0.17 | 1.0 1.50 |

0.40 0.65 |

--- | 0.50 0.80 |

0.04 | 0.45 0.65 |

--- |

| ASTM A 204 Gr-B |

0.035 | 0.20 | --- | 0.90 | --- | 0.15 0.40 |

0.04 | 0.45 0.60 |

--- |

| Gr 12 - Cl 2 | 0.035 | 0.17 | 0.80 1.15 |

0.40 0.65 |

--- | 0.15 0.40 |

0.04 | 0.45 0.60 |

--- |

| 16 Mo3 | 0.030 | 0.12 0.20 |

0.30 | 0.40 0.90 |

0.30 | 0.35 | 0.025 | 0.25 0.35 |

--- |

| EN-19 | 0.20 0.40% |

0.35 0.45% |

0.90 1.50% |

0.50 0.80% |

--- | 0.10 0.35% |

--- | --- 0.05 |

--- |

| Gr 22 - Cl 2 | 0.035 | 0.15 | 2.0 2.5 |

0.30 0.60 |

--- | 0.50 | 0.035 | 0.90 1.10 |

--- |

The ready stock of ASTM A387 Alloy Sheet, Alloy Steel Circle Uses of renowned mills as per Alloy Steel Foils, ASME SA387 Alloy Steels Class 1 Cold Rolled Plates ASME/ANSI, Alloy Steels Plates Suppliers In Bhopal.

Alloy Steel Cold Rolled Plates Grade List

- ASTM A387 Grade 5 Class 2, Grade 9 Class 2, Grade 11 Class 2, Grade 12 Class 2, Grade 22 Class 2, Grade 91 Class 2.

- ASME SA387 Grade 5 Class 2, Grade 9 Class 2, Grade 11 Class 2, Grade 12 Class 2, Grade 22 Class 2, Grade 91 Class 2.

- EN 10028: 16Mo3, 13CrMo45, 10CrMo010

- BS 1501: 620B, 621B, 622B

Price of Alloy Steel Plate Suppliers in India

| Description | Unit | Per Unit (INR) |

|---|---|---|

| Alloy Steel Wear Plates | KGS | 101 |

| Low Alloy Steel Plate | KGS | 31 |

| Alloy Steel Hot Rolled Plates | KGS | 120 |

| Low Alloy Steel Plate Material | KGS | 118 |

| Hot Rolled Alloy Steel Plate | KGS | 150 |

| High Strength Low Alloy Steel Plate | KGS | 79 |

| Low Alloy Steel Plates | KGS | 87 |

| Nickel Alloy Steel Plate | KGS | 79 |

| Alloy Steel Plate Material | KGS | 94 |

| ASTM A387 Alloy Sheet | KGS | 47 |

| Alloy Steel Circle | KGS | 59 |

| ASME SA 387 Alloy Steel Plates | KGS | 100 |

| Chrome Molybdenum Alloy Steel Plate | KGS | 47 |

| SA387 Alloy Steel Plates | KGS | 104 |

Temperature Limit of Alloy Steel Sheet

ASTM A387 Alloy Steel Sheet is applied in the temperature range between 316℃ to 593℃. The elevated temperature properties of it are still of particular interest, even with the current trend towards applications with high CVN toughness requirements.

High Nickel Alloys Plates Tensile and Yield Strength

| Grade |

Bend | Tensile Strength | Yield Strength | % Elongational | |

| 50 GL | 50 GL | ||||

| Gr 5 - Cl 2 | --- | 515 690 |

310 | --- | 18 |

| Gr 11 - CI 2 | --- | 515 690 |

310 | 18 | 22 |

| ASTM A 204 Gr-B |

2T | 485 620 |

275 | 17 | 21 |

| Gr 12 - Cl 2 | --- | 450 585 |

275 | 19 | 22 |

| 16 Mo3 | Impact : +20C / 3 |

440 590 |

275 | --- | 24 |

| EN-19 | --- | --- --- |

--- | --- | --- |

| Gr 22 - Cl 2 | --- | 515 690 |

310 | --- | 18 |

Alloy Steel Foils HS code

| HS Code | Description |

| 72254020 | Alloy Steel Hot Rolled Sheet and Plate |

ASTM A387 Alloy Steel Plates Weight Chart

Sheet – Metric

| Thickness mm |

Size m |

Weight kg/sheet |

| 0.300 mm | 2 x 1 | 4.7 |

| 0.376 mm | 2 x 1 | 5.9 |

| 0.400 mm | 2 x 1 | 6.3 |

| 0.457 mm | 2 x 1 | 7.2 |

| 0.500 mm | 2 x 1 | 7.9 |

| 0.559 mm | 2 x 1 | 8.8 |

| 0.600 mm | 2 x 1 | 9.4 |

| 0.710 mm | 2 x 1 | 11.1 |

| 0.800 mm | 2 x 1 | 12.6 |

| 0.914 mm | 2 x 1 | 14.3 |

| 1.000 mm | 2 x 1 | 15.7 |

| 1.200 mm | 2 x 1 | 18.8 |

| 1.220 mm | 2 x 1 | 19.2 |

| 1.270 mm | 2 x 1 | 19.9 |

| 1.420 mm | 2 x 1 | 22.3 |

| 1.600 mm | 2 x 1 | 25.1 |

| 1.780 mm | 2 x 1 | 28.0 |

| 2.000 mm | 2 x 1 | 31.4 |

| 2.030 mm | 2 x 1 | 31.9 |

| 2.286 mm | 2 x 1 | 35.9 |

| 2.500 mm | 2 x 1 | 39.3 |

| 2.540 mm | 2 x 1 | 39.9 |

| 2.640 mm | 2 x 1 | 41.4 |

| 3.000 mm | 2 x 1 | 47.1 |

| 3.250 mm | 2 x 1 | 51.0 |

| 4.000 mm | 2 x 1 | 62.8 |

| 4.060 mm | 2 x 1 | 63.7 |

| 4.460 mm | 2 x 1 | 70.0 |

| 4.760 mm | 2 x 1 | 74.7 |

| 5.000 mm | 2 x 1 | 78.5 |

| 6.000 mm | 2 x 1 | 94.2 |

Sheet – Imperial

| Thickness in |

Size ft |

Weight lbs/sheet |

| 0.012 inches | 10×3 | 14.7 |

| 0.014 inches | 10×3 | 17.2 |

| 0.016 inches | 10×3 | 19.6 |

| 0.018 inches | 10×3 | 22.1 |

| 0.020 inches | 10×3 | 24.5 |

| 0.022 inches | 10×3 | 27.0 |

| 0.024 inches | 10×3 | 29.4 |

| 0.028 inches | 10×3 | 34.4 |

| 0.032 inches | 10×3 | 39.3 |

| 0.036 inches | 10×3 | 44.2 |

| 0.040 inches | 10×3 | 49.1 |

| 0.047 inches | 10×3 | 57.7 |

| 0.048 inches | 10×3 | 58.9 |

| 0.050 inches | 10×3 | 61.3 |

| 0.056 inches | 10×3 | 68.7 |

| 0.063 inches | 10×3 | 77.3 |

| 0.070 inches | 10×3 | 85.9 |

| 0.078 inches | 10×3 | 95.7 |

| 0.080 inches | 10×3 | 98.2 |

| 0.090 inches | 10×3 | 110.4 |

| 0.100 inches | 10×3 | 120.2 |

| 0.098 inches | 10×3 | 120.2 |

| 0.104 inches | 10×3 | 122.7 |

| 0.118 inches | 10×3 | 144.8 |

| 0.128 inches | 10×3 | 157.0 |

| 0.157 inches | 10×3 | 192.6 |

| 0.160 inches | 10×3 | 196.3 |

| 0.176 inches | 10×3 | 215.9 |

| 0.187 inches | 10×3 | 229.4 |

| 0.197 inches | 10×3 | 241.7 |

| 0.236 inches | 10×3 | 289.5 |

Plate – Metric

| Thickness mm |

Size m |

Weight kg/plate |

| 6.35 mm | 2 x 1 | 99.7 |

| 10.00 mm | 2 x 1 | 157.0 |

| 12.70 mm | 2 x 1 | 199.4 |

| 15.00 mm | 2 x 1 | 235.5 |

| 20.00 mm | 2 x 1 | 314.0 |

| 25.40 mm | 2 x 1 | 398.8 |

| 30.00 mm | 2 x 1 | 471.0 |

| 38.10 mm | 2 x 1 | 598.2 |

| 40.00 mm | 2 x 1 | 628.0 |

| 50.00 mm | 2 x 1 | 785.0 |

| 50.80 mm | 2 x 1 | 797.6 |

| 60.00 mm | 2 x 1 | 942.0 |

| 63.50 mm | 2 x 1 | 997.0 |

| 70.00 mm | 2 x 1 | 1099.0 |

| 76.20 mm | 2 x 1 | 1196.3 |

| 80.00 mm | 2 x 1 | 1256.0 |

| 90.00 mm | 2 x 1 | 1413.0 |

| 100.00 mm | 2 x 1 | 1570.0 |

| 101.60 mm | 2 x 1 | 1595.1 |

| 110.00 mm | 2 x 1 | 1727.0 |

| 120.00 mm | 2 x 1 | 1884.0 |

| 127.00 mm | 2 x 1 | 1993.9 |

| 130.00 mm | 2 x 1 | 2041.0 |

| 140.00 mm | 2 x 1 | 2198.0 |

| 150.00 mm | 2 x 1 | 2355.0 |

| 152.40 mm | 2 x 1 | 2392.7 |

Plate – Imperial

| Thickness in |

Size ft |

Weight lbs/plate |

| 1/4 inches | 10 x 3 | 306.7 |

| 1/2 inches | 10 x 3 | 613.4 |

| 3/4 inches | 10 x 3 | 920.2 |

| 1 inches | 10 x 3 | 1226.9 |

| 1 1/4 inches | 10 x 3 | 1533.6 |

| 1 1/2 inches | 10 x 3 | 1840.3 |

| 2 inches | 10 x 3 | 2453.8 |

| 2 1/2 inches | 10 x 3 | 3067.2 |

| 2 3/4 inches | 10 x 3 | 3373.9 |

| 3 inches | 10 x 3 | 3680.6 |

| 4 inches | 10 x 3 | 4907.5 |

| 5 inches | 10 x 3 | 6134.4 |

| 5 1/2 inches | 10 x 3 | 6747.8 |

| 6 inches | 10 x 3 | 7361.3 |

Density based on 7.85 g/cm3

(0.284 lbs/in3)

Alloy Steel Sheet Laser Cutting

Laser cut metal tolerances

- Steel thickness under 1.0mm, tolerances is +/- 0.12 mm.

- From 1.0 mm to 3.0 mm, tolerances allowed +/- 0.15 mm.

- From 3.0 mm to 6.0 mm, +/- 0.20 mm.

- 6.0 mm to 15.0 mm, laser cutting tolerances at +/- 0.25 mm.

- Up 15.0 mm to 20.0 mm, laser cut tolerances at +/- 0.75 mm.

Chrome Molybdenum Alloy Steel Plates Uses and Applications

- Forged Fittings for Chemical

- Dairy Suryadeep

- Food, Beverage

- Oil and Gas

- Power Generation

- Petrochemicals and Refineries

- Petroleum Refining

- Marine & Dredging

- Thermal, Nuclear and Solar Power Plants

ASME SA 387 Alloy Steel Structural Plate Welding Material

Welding of such material is done at the raised temperatures. The Alloy Steels Plates Manufacturer preheat temperature and interpass temperature is kept within the extend of 400-550 F. Beneath these said Properties and Welding Procedure the welding was done.