Supplier of Aluminium UNS A93003 Plate, ASTM B209 Aluminum Alloy 3003 Plates Stockist In India.

Aluminium 3003 Sheet is made up of a commercially pure aluminum material that has high mechanical properties. Suryadeep Industry is a supplier and distributor of the 3003 Aluminium Plates in different forms and dimensions. The material has a medium strength compared to most metallic alloys. The 3003 Aluminium Hot Rolled Plate also has very good corrosion resistance to atmospheric components. The material has improved mechanical properties compared to the other grades of aluminum. The Aluminium 3003 Chequered Plate and others can be worked upon. They have good formability and machinability. The applications of the material are in chemical equipment manufacturing, cooking and kitchen appliances, heat exchangers and in storage tanks. The ASTM B209 Aluminum Alloy 3003 Plates have 98.6% aluminum in the composition with manganese and copper included.

The composition allows the 3003 Aluminium HR Plate to have high temperature capabilities. The melting point of the material is 644 degrees Celsius. And the density of the Aluminium 3003 Perforated Sheets is 2.73 grams per cubic centimeter. The material also has good tensile strength with minimum130MPa and minimum 125MPa yield strength. It has 55MPa fatigue strength and the Aluminium 3003 Coils have 83MPa shear strength as well. They have good elongation and elastic modulus values with hardness. The hardness is 35BNH for the ASME SB209 Aluminium 3003 Sheets. The applications include eyelet stock, awning slats, garage doors, storage tanks, ice cube trays, cooking utensils and many more. There are different forms such as strips, coils, foils and Aluminium 3003 Circle in this grade of material. Please feel free to contact us for more information on the product and the 3003 Aluminium CR Sheets prices.

Table of Content - 3003 Aluminium HR Plate Specification And Material Grade - Aluminium 3003 Plate Chemical Composition Chart - Aluminium DIN 3.0517 Sheets Mechanical Strength Table - Basic Types Of Aluminium 3003 Sheet - Equivalent Grades Of Aluminium 3003 Coils - ASTM B209 Aluminum Alloy 3003 Plates Weight Chart

3003 Aluminium HR Plate Specification And Material Grade

| Standards | ASTM B209 / ASME SB209 |

|---|---|

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. |

| Temper | O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851 |

| Finish | Mill, Customer specific finish |

| Thickness | 0.2~300mm |

| Width | 500~2500mm |

| Type | Hot-Rolled (HR) / Cold-Rolled (CR) Sheet / Plates/ Strips/ Coils/ Chequered Plates |

| Aluminum Sheet/ Plate Coating | PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating |

| Length | 500~10000mm |

Global Suppliers of 3003 Aluminium Plates In India, Contact US Today For Buy 3003 Aluminium Hot Rolled Plate, Specification Of Aluminium 3003 Chequered Plate.

Aluminium 3003 Plate Chemical Composition Chart

| Mn | Al | Fe | Cu | Si | Other Total | Zn |

| 1.0 to 1.5% | Remainder | 0.7% | 0.05 to 0.20% | 0.6% | 0.15% | 0.10% |

Aluminium DIN 3.0517 Sheets Mechanical Strength Table

Aluminium 3003 Sheet Chemical And Mechanical Composition Of 3003 Aluminium HR Plate, Aluminium 3003 Perforated Sheets Stockist In India, Check Our Global Sales Network For Aluminium 3003 Coils.

| Properties | Imperial | Metric |

| Tensile strength | 18855 psi | 130 MPa |

| Yield strength | 18130 psi | 125 MPa |

| Shear strength | 12039 psi | 83 MPa |

| Fatigue strength | 7977 psi | 55 MPa |

| Elastic modulus | 10153-11603 ksi | 70-80 GPa |

| Poisson's ratio | 0.33 | 0.33 |

| Elongation | 10% | 10% |

| Hardness | 35 | 35 |

Basic Types Of Aluminium 3003 Sheet

ASME SB209 Aluminium 3003 Sheets Supplier In India, We provide Aluminium 3003 Circle with instant delivery, Stockist Of Aluminium UNS A93003 Sheets.

3003 Aluminium Hot Rolled Plate

3003 Aluminium Hot Rolled Plate

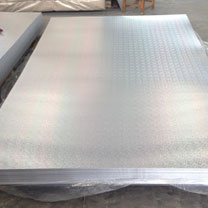

Aluminium 3003 Chequered Plate

Aluminium 3003 Chequered Plate

ASTM B209 Aluminum Alloy 3003 Plates

ASTM B209 Aluminum Alloy 3003 Plates

3003 Aluminium HR Plate

3003 Aluminium HR Plate

Aluminium 3003 Perforated Sheets

Aluminium 3003 Perforated Sheets

Aluminium 3003 Coils

Aluminium 3003 Coils

ASME SB209 Aluminium 3003 Sheets

ASME SB209 Aluminium 3003 Sheets

Aluminium 3003 Circle

Aluminium 3003 Circle

Aluminium UNS A93003 Sheets

Aluminium UNS A93003 Sheets

Aluminium Alloy 3003 Extruded Sheets

Aluminium Alloy 3003 Extruded Sheets

3003 Aluminium CR Sheets

3003 Aluminium CR Sheets

Aluminium DIN 3.0517 Sheets

Aluminium DIN 3.0517 Sheets

Equivalent Grades Of Aluminium 3003 Coils

Accept all small/ Large Orders Aluminium Alloy 3003 Extruded Sheets, Weight Chart Of 3003 Aluminium CR Sheets, View Aluminium DIN 3.0517 Sheets Grades Equivalent.

| European Standard | UNS | OLD | ISO | WNr | GERMANY (DIN) | USA (AA) |

| AW-AlCu4Mg1 | A93003 | AU4G1 | AlCu4Mg | 3.0517 | AlCuMg2 | 3003 |

ASTM B209 Aluminum Alloy 3003 Plates Weight Chart

Width: 1.000 mm | Length: 2.000 mm

| Thickness(milimeter) | Weight |

|---|---|

| 0,30 | 0,810 Kg/m2 |

| 0,40 | 1,080 Kg/m2 |

| 0,50 | 1,350 Kg/m2 |

| 0,60 | 1,620 Kg/m2 |

| 0,70 | 1,890 Kg/m2 |

| 0,80 | 2,160 Kg/m2 |

| 0,90 | 2,430 Kg/m2 |

| 1,00 | 2,700 Kg/m2 |

| 1,20 | 3,240 Kg/m2 |

| 1,40 | 3,780 Kg/m2 |

| 1,50 | 4,050 Kg/m2 |

| 1,60 | 4,320 Kg/m2 |

| 1,80 | 4,860 Kg/m2 |

| 2,00 | 5,400 Kg/m2 |

| 2,20 | 5,940 Kg/m2 |

| 2,50 | 6,750 Kg/m2 |

| 3,00 | 8,100 Kg/m2 |

| 4,00 | 10,800 Kg/m2 |

| 5,00 | 13,500 Kg/m2 |

| 6,00 | 16,200 Kg/m2 |

| 10,00 | 27,000 Kg/m2 |

| 12,00 | 32,400 Kg/m2 |

| 15,00 | 40,500 Kg/m2 |

| 20,00 | 54,000 Kg/m2 |