Get Free Quote Of 2205 Duplex Sheet, ASTM A240 Duplex Steel Plate.

Duplex Plate is made up of a type of steel that is called duplex. There are different steel types such as ferritic, austenitic, martensitic and duplex. The duplex is special in that it has austenitic and ferritic features in its metallurgic microstructure. So the ASTM A240 Duplex Steel Plate is a pressure vessel quality duplex stainless steel plate that has the ferritic strength and the austenitic corrosion resistance in it. Because the Duplex Stainless Steel Plates have both the qualities and tend to extremely corrosion resistant and work hardenable, they are also cost effective in the long run. There are different types of duplex steels but the 2205 Duplex Plate is one of the most used and cost effective of them all. There are different shapes, forms, sizes and finishes to the plates such as the Duplex 2B Finish Plate and other types.

The tensile strength of this 2205 duplex grade is 620MPa and the minimum yield strength is 450MPa. There are other Duplex Steel Sheet grades that have very high strength and very high corrosion resistance. The duplex is also classified as duplex, super duplex and lean duplex grades. The Duplex 2205 Plates belong to the standard duplex grade. The materials can be heat treated, welded upon and work hardened. All of these properties make the ASTM A240 UNS S31803 Plate and other grade plates be applied in a wide range of applications. The applications include pulp and paper industries, chemical processing plants, oil and gas industries, and in transportation and storage. The ASTM A240 UNS S32205 Sheet is also used in marine environments and in pollution control systems as well. Please contact us for any orders in any grades of duplex steel plates.

Table of Content - 2205 Duplex Plate Material Standards And Grades - ASTM A240 Duplex Steel Plate Weight Chart - Duplex 2205 Plates Size chart - List Of Duplex Plate Types - SA-240 Duplex 2205 Plate Equivalent Grades - Duplex S31803 Plate Chemical Resistance Guide - Duplex Steel 2205 Plate Mechanical Properties Database - Duplex 2205 Sheet Tensile Properties - 2205 Duplex Stainless Steel Plate Uses - Difference between duplex 2205 Plate, Sheet, & Foil

2205 Duplex Plate Material Standards And Grades

| Material | Duplex 2205 Sheet & Duplex 2205 Plate |

|---|---|

| Standard Suryadeep Specifications |

|

| Length | 2m, 2.44m, 3m, or as required |

| Value added services |

|

| Specification | ASTM A240 / ASME SA240 |

| Plasma profiles | As per customer's drawings |

| Standard Sizes | 1000 x 2000 mm, 1220 x 2440 mm, 1500 x 3000 mm, 2000 x 2000 mm, 2000 x 4000 mm |

| Stock available in form of | Shim Sheet, Rolls, Strip, Flats, Clad Plate, Plain Sheet, Plate, Sheet, Coils, Foils, Rolling Sheet, Rolling Plate, Flat Shim, Flat Sheet, Blank (Circle), soft annealed, sheared, annealed, tread plate,descaled, Checker Plate |

| Tolerances of Width and thickness |

|

| Avesta 2205 Plate & Sheet Distributors | Sail, Jindal, Shah Alloys, Outokumpu, BAOSTEEL, TISCO, JISCO, LISCO, POSCO, ZPSS |

| Width | 10-2500mm |

| Why choose Metal tube? |

|

| Sheet Thickness | 0.1mm to 100 mm Thk |

| Finish | 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated), Cold rolled sheet (CR), Hot rolled plate (HR), No.1 finish hot rolled 2205 Duplex Plate, 2B, 1D, BA, No.4, 8K, hairline, satin, brush, mirror etc. |

| Hardness | Quarter Hard, Half Hard,Spring Hard, Soft, Hard, Duplex 2205 Sheet suppliers |

| Profiling | To provide a full profiling service in India we use numerous profiling methods including:

|

| Specialized in |

|

Buy Duplex Stainless Steel Plates, ASTM A240 Type 2205 Duplex Sheet At Low Price, Standards Dimensions Of Duplex Steel 2D Finish Plates, Duplex 2B Finish Plate Specification.

Saf 2205 Sheet Melting Range

| ASTM A240 Type 2205 Plate melting range |

| 2525-2630°F |

| Poisson’s Ratio | 0.3 |

| Specific Heat Capacity at 212°F | 0.119 Btu/lb/°F |

| Elastic Modulus at 72°F | 29 x 10 psi |

| Thermal Conductivity at 212°F | 8.4 Btu/hr-ft-°F |

Duplex Stainless Steel Plates Density

We provide Multiple Payment Options Of SA-240 Duplex 2205 Plate, Contact US Today For Buy Duplex Chequered Plate, Distributor Of Duplex 2205 Plates In India.

| UNS S32205 duplex 2205 Plate density |

| 0.278 lb/in3 |

ASTM A240 Duplex Steel Plate Weight Chart

| Thickness | Plate Weight per Unit Area | Density |

|---|---|---|

| 3/16 inches | 0.06000 lbs/in²42.184176 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/4 inches | 0.08 lbs/in²56.245568 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/8 inches | 0.121 lbs/in²85.0714216 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/2 inches | 0.161 lbs/in²113.1942056 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 5/8 inches | 0.196 lbs/in²137.8016416 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/4 inches | 0.235 lbs/in²165.221356 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 7/8 inches | 0.274 lbs/in²192.6410704 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 inches | 0.313 lbs/in²220.0607848 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/4 inches | 0.391 lbs/in²274.9002136 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/2 inches | 0.47 lbs/in²330.442712 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 3/4 inches | 0.549 lbs/in²385.9852104 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 inches | 0.627 lbs/in²440.8246392 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/4 inches | 0.705 lbs/in²495.664068 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/2 inches | 0.784 lbs/in²551.2065664 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 3/4 inches | 0.862 lbs/in²606.0459952 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3 inches | 0.941 lbs/in²661.5884936 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

Duplex 2205 Plates Size chart

| Stocked Sizes | |

|---|---|

| Size (in inches) | Size (in milimeter) |

| .125" | 3.18mm |

| .134" | 3.40mm |

| .156" | 3.96mm |

| .187" | 4.75mm |

| .250" | 6.35mm |

| .312" | 7.92mm |

| .375" | 9.53mm |

| .500" | 12.7mm |

| .625" | 15.9mm |

| .750" | 19.1mm |

| .875" | 22.2mm |

| 1" | 25.4mm |

| 1.125" | 28.6mm |

| 1.250" | 31.8mm |

| 1.500" | 38.1mm |

| 1.750" | 44.5mm |

| 2" | 50.8mm |

| 2.500" | 63.5mm |

| 3" | 76.2mm |

List Of Duplex Plate Types

ASTM A240 Duplex Steel Plate

ASTM A240 Duplex Steel Plate

Duplex Stainless Steel Plates

Duplex Stainless Steel Plates

2205 Duplex Plate

2205 Duplex Plate

Duplex Steel 2D Finish Plates

Duplex Steel 2D Finish Plates

Duplex 2B Finish Plate

Duplex 2B Finish Plate

SA-240 Duplex 2205 Plate

SA-240 Duplex 2205 Plate

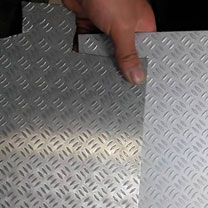

Duplex Chequered Plate

Duplex Chequered Plate

Duplex 2205 Plates

Duplex 2205 Plates

ASME SA240 Duplex Steel Plate

ASME SA240 Duplex Steel Plate

Duplex Hot Rolled Plate

Duplex Hot Rolled Plate

Duplex S31803 Plate

Duplex S31803 Plate

Duplex Steel 2205 Plate

Duplex Steel 2205 Plate

Duplex Steel 2D Finish Plates Welding

- Gas metal arc welding MIG (GMAW)

- Shielded metal arc welding (SMAW)

- Resistance welding

- Laser welding

- Submerged arc welding (SAW)

- Gas tungsten arc welding TIG (GTAW)

- Plasma arc welding (PAW)

- Flux-cored arc welding (FCW)

- High-frequence welding

| Type | Typical Base Metal Composition | Grade | UNS No. | GMAW / SAW / GTAW Autrod / Tigrod |

FCAW |

|---|---|---|---|---|---|

| Duplex | 23Cr, 4Ni, 0.10N | (SAF) 2304, UR35N | S32304/ 1.4362 | ER2209 | SB 2209 |

| Duplex | 22Cr, 5.5Ni, 3Mo, 0.15N | (SAF) 2205, UR45N | S31803 /1.4462 S32205 | ER2209 | SB 2209 |

| Duplex | 25Cr, 7Ni, 3Mo, 0.14N | DP3 | S31260 | ER2509 | SB 2509 |

| Super Duplex | 25Cr, 6.5Ni, 3Mo, 0.18N | UR47N | S31200 | ER2509 | SB 2509 |

| Super Duplex | 25Cr, 6Ni, 3Mo, 2Cu, 0.20N | Ferralium 255 UR52N+ |

S32550 | ER2509 | SB 2509* |

| Super Duplex | 25Cr, 6Ni, 3Mo, 0.7Cu, 0.7W, 0.25N | Zeron 100 | S32760 | ER2509 | SB 2509* |

| Super Duplex | 25Cr, 7Ni, 4Mo, 0.25N | (SAF) 2507 | S32750 | ER2509 | SB 2509 |

Duplex 2B Finish Plate Imperial Dimensions

We provide ASME SA240 Duplex Steel Plate Expert Service In Bhopal, Get Duplex Hot Rolled Plate At Best Price, India, Get a Live Quote Now For Duplex S31803 Plate, Duplex Steel S31803 Plates.

| Surface finish | Thickness (inches) | Width (inches) |

|---|---|---|

| 1 – Duplex 2205 Hot rolled, heat treated, pickled Plate & Sheet | .1000 – .3750 | max. 72 |

| 2R – Duplex 2205 Cold-rolled, bright-annealed Sheet & Plate | 0.002–0.06 | 0.118–25.551 |

| 2H – Duplex 2205 Work hardened Plate & Sheet | 0.002–0.06 | 0.118–24.803 |

| 2B – Duplex 2205 Cold rolled, heat treated, pickled, skin passed Sheet & Plate | 10–24 | 72* |

| 2D – Duplex 2205 Cold rolled, heat treated, pickled Plate & Sheet | 12–24 | 60 |

| BA Mexinox only | 18–28 | 48 |

| Deco Rolled-On Mexinox only | 14–28 | 48 |

| Duplex 2205 Polished Plate & Sheet (not brushed) | 11–24 | 60 |

| Temper rolled Mexinox only | 13–29 | 48 |

SA 240 Duplex UNS S32205 Coil Metric Dimensions

| Surface finish | Thickness (milimeter) | Width (milimeter) |

|---|---|---|

| Duplex 2205 1D – Hot rolled, heat treated, pickled Plate & Sheet | 2.4–12.7 | 2032 |

| 2R – Duplex 2205 Cold-rolled, bright-annealed Sheet & Plate | 0.05–1.50 | 3–649 |

| 2H – Duplex 2205 Work hardened Plate & Sheet | 0.05–1.50 | 3–630 |

| 2B – Duplex 2205 Cold rolled, heat treated, pickled, skin passed Sheet & Plate | 0.25–8.0 | 2032 |

| 2D – Duplex 2205 Cold rolled, heat treated, pickled Plate & Sheet | 0.4–6.35 | 1524 |

| 2E – Duplex 2205 Cold rolled, heat treated, mechanically descaled Sheet & Plate | 0.4–8.0 | 2032 |

| 2R – Duplex 2205 Cold rolled, bright annealed Plate & Sheet | 0.25–3.5 | 1524 |

| 2H – Duplex 2205 Work hardened Sheet & Plate | 0.4–6.35 | 1524 |

| Duplex 2205 Polished, brushed Plate & Sheet | 0.5–4.0 | 1524 |

| Deco | 0.3–3.5 | 1524 |

| Duplex 2205 Coil | 0.30–3.5 |

1,524 |

SA-240 Duplex 2205 Plate Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Duplex 2205 Plate | 1.4462 / 1.4462 | UNS S31803 / UNS S32205 |

Duplex S31803 Plate Chemical Resistance Guide

Duplex Steel 2205 Plate Distributor in India, Check Duplex Plate Chemical Composition, One Stop Shop For All Duplex 2205 Sheet, SA 240 Duplex UNS S32205 Coil.

| Element | Percent By Weight | |

|---|---|---|

| P | Phosphorous | 0.03% max |

| Cr | Chromium | 22.0 - 23.0% |

| C | Carbon | 0.03% max |

| Ni | Nickel | 4.5 - 6.5% |

| N | Nitrogen | 0.1 - 0.2% |

| Mn | Manganese | 2.0% max |

| Mo | Molybdenum | 3.0 - 3.5% |

| Si | Silicon | 1.0% max |

| Fe | Iron | Balance |

| S | Sulfur | 0.02% max |

Duplex Steel 2205 Plate Mechanical Properties Database

| Mechanical property | Value |

|---|---|

| Elongation, % | 25 minimum |

| 0.2% Yield Strength, ksi | 65 minimum |

| Hardness [HRC] | 293 maximum |

| Tensile Strength, ksi | 90 minimum |

Duplex 2205 Sheet Tensile Properties

| Ultimate Tensile Strength, ksi Minimum | Hardness Max. | .2% Yield Strength, ksi Minimum |

|---|---|---|

| 95 | 31 Rockwell C | 65 |

2205 Duplex Stainless Steel Plate Uses

- Food processing equipment

- Pulp mill digesters, bleach washers, chip pre-steaming vessels

- Oil field piping and heat exchangers

- Chemical process vessels, piping and heat exchangers

- Flue gas desulfurization equipment

Difference between duplex 2205 Plate, Sheet, & Foil

- Thickness greater than 6.35 mm is called a duplex 2205 Plate.

- Thickness greater than 0.15 mm and less than 6.35mm is called a duplex 2205 Sheet.

- Thickness less than 0.15mm is called a duplex 2205 Foil.