Buy 1100 Aluminium Alloy Plates, UNS A91100 Sheet at factory price in Bhopal, India.

Aluminium 1100 Sheet comes under the specification ASTM/ASME SB209. The material comes in sheets, foils coils, and other forms. The 1100 Aluminium Alloy Plates are used in different industries for corrosion resistance and strength. The UNS A91100 Plate has moderate strengths compared to other metal alloy products but is highly corrosion resistant. The Aluminium Alloy 1100 Perforated Sheet is made up of aluminum, copper, silicon, iron, manganese, zinc and other trace elements. The material is a commercially pure grade of aluminum. Aluminium Alloy 1100 Chequered Plate and other finished products have high welding abilities and forming abilities. The plates could be made as cold rolled or hot rolled. The 1100 Aluminium Hot Rolled Plate has 3.5ksi minimum yield strength and up to 15.5ksi tensile strength. The plates come in 0.2mm to 300mm thickness.

The width of the ASTM B209 Aluminium Alloy 1100 Sheet can vary from 500mm to 2500mm and the length varies from 500mm to 10000mm. There are different finishes available. The mill finish is the most common where the customer specific finishes are possible as well. The Alloy A91100 Sheet comes in CR sheet, plate, strip, coil and checkered plate types. The plates can be cold rolled and hot rolled. The Aluminium Alloy 1100 Hot Rolled Plate can also support the cutting, forming, machining, drilling, grinding and polishing operations. The Aluminum 1100 Cold Rolled Sheet can perform under reducing environments. The material has very low density and is mainly used in aircraft components. Passivation provides the material with excellent corrosion resistance. Please contact us for ASME SB209 Aluminium Alloy 1100 Diamond Plate and other types of plate information and price.

Table of Content - 1100 Aluminium Plates Schedule Standard And Specification - Equivalent Grades Of UNS A91100 Plate - Aluminium 1100 Coils Chemical Compatibility Chart - 1100 Aluminium Sheets Mechanical Behaviour - List Of Aluminium 1100 Sheet Types - Alloy A91100 Sheet Weight Chart

1100 Aluminium Plates Schedule Standard And Specification

| Standards | ASTM B209 / ASME SB209 |

|---|---|

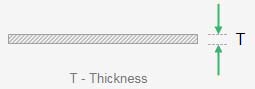

| Thickness | 0.2~300mm |

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc |

| Width | 500~2500mm |

| Temper | O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851 |

| Finish | Mill, Customer specific finish |

| Length | 500~10000mm |

Distributor Of Aluminium 1100 Perforated Sheets In India, Aluminium 1100 Chequered Plate Grade Equivalent, 1100 Aluminium Sheets Specification.

Equivalent Grades Of UNS A91100 Plate

| UNS | France | Japan | ISO | USA |

| A91100 | NF 1100 | JIS A1100P | Al 99.0 Cu. | AA1100 |

Aluminium 1100 Coils Chemical Compatibility Chart

1100 Aluminium Hot Rolled Plate Chemical And Mechanical Composition Of 1100 Aluminium Plates, Aluminium 1100 Coils Stockist In India, Check Our Global Sales Network For ASTM B209 Aluminium Alloy 1100 Sheet.

| Alloy 1100 | Zn | Fe | Ti | Si | Cr | Mg | Others | Mn | AI | Cu |

| minimum | 0.01 | 0.35 | 0.020 | 0.25 | Trace | 0.01 | 0.05 (each) | 0.01 | 99.60% | 0.05 |

| maximum | 0.05 | 0.50 | 0.030 | 0.35 | Trace | 0.03 | 0.15 (total) | 0.05 | remainder | 0.20 |

1100 Aluminium Sheets Mechanical Behaviour

| Alloy | Temper | UTS(Mpa) | % Elongation | |||

| Max | Min | 0.81 mm - 1.30 mm | 0.5 mm -0.8 mm | 1.30 mm - above | ||

| 1100 | O | 110 | 75 | 25 | 20 | 29 |

| H12 | 130 | 95 | 6 | 5 | 7 | |

| H14 | 145 | 110 | 4 | 3 | 5 | |

| H16 | 165 | 130 | 3 | 2 | 4 | |

| H18 | --- | 150 | 2 | 2 | 3 | |

List Of Aluminium 1100 Sheet Types

Alloy A91100 Sheet Stockist In India, Fastest Growing Supplier Of 1100 Aluminium Hot Rolled Plate, Get at discount of Aluminum 1100 Cold Rolled Sheet, Aluminium Alloy 1100 Sheets Distributor In India.

UNS A91100 Plate

UNS A91100 Plate

Aluminium 1100 Perforated Sheets

Aluminium 1100 Perforated Sheets

Aluminium 1100 Chequered Plate

Aluminium 1100 Chequered Plate

1100 Aluminium Sheets

1100 Aluminium Sheets

1100 Aluminium Hot Rolled Plate

1100 Aluminium Hot Rolled Plate

1100 Aluminium Plates

1100 Aluminium Plates

Aluminium 1100 Coils

Aluminium 1100 Coils

ASTM B209 Aluminium Alloy 1100 Sheet

ASTM B209 Aluminium Alloy 1100 Sheet

Alloy A91100 Sheet

Alloy A91100 Sheet

1100 Aluminium Hot Rolled Plate

1100 Aluminium Hot Rolled Plate

Aluminum 1100 Cold Rolled Sheet

Aluminum 1100 Cold Rolled Sheet

Aluminium Alloy 1100 Sheets

Aluminium Alloy 1100 Sheets

Alloy A91100 Sheet Weight Chart

Refer ASME SB209 Aluminium Alloy 1100 Diamond Plate Dimensions And Weight Chart, Looking to buy Aluminium 1100 Sheet? contact Suryadeep Industry, A Reliable 1100 Aluminium HR Plate Distributor in India

Width: 1.000 mm | Length: 2.000 mm

| Thickness(milimeter) | Weight |

|---|---|

| 0,30 | 0,810 Kg/m2 |

| 0,40 | 1,080 Kg/m2 |

| 0,50 | 1,350 Kg/m2 |

| 0,60 | 1,620 Kg/m2 |

| 0,70 | 1,890 Kg/m2 |

| 0,80 | 2,160 Kg/m2 |

| 0,90 | 2,430 Kg/m2 |

| 1,00 | 2,700 Kg/m2 |

| 1,20 | 3,240 Kg/m2 |

| 1,40 | 3,780 Kg/m2 |

| 1,50 | 4,050 Kg/m2 |

| 1,60 | 4,320 Kg/m2 |

| 1,80 | 4,860 Kg/m2 |

| 2,00 | 5,400 Kg/m2 |

| 2,20 | 5,940 Kg/m2 |

| 2,50 | 6,750 Kg/m2 |

| 3,00 | 8,100 Kg/m2 |

| 4,00 | 10,800 Kg/m2 |

| 5,00 | 13,500 Kg/m2 |

| 6,00 | 16,200 Kg/m2 |

| 10,00 | 27,000 Kg/m2 |

| 12,00 | 32,400 Kg/m2 |

| 15,00 | 40,500 Kg/m2 |

| 20,00 | 54,000 Kg/m2 |