Pure Ti Plate, AMS 4901 Titanium Sheet Distributor In India.

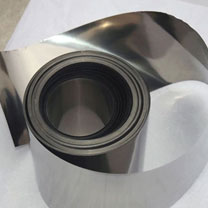

Titanium Sheet is made up of titanium material. There are different grades of titanium products including commercially pure titanium grades. The Titanium Plate can be made up of any of these grades and the corrosion resistance and mechanical properties vary according to the grade. Titanium is a naturally strong element. So the Pure .125 titanium sheet and other types of sheets and plates are stronger. Suryadeep Industry is a distributor and leading distributor of titanium sheets and Titanium Coil products. All titanium grades are formable but some grades require special attention on forming. The materials also have to overcome the galling and springback issues. The .012 titanium sheet has to cleaned up of any scratches before forming. The material is notch sensitive and can deform with surface impurities.

There are different dimensions to the sheets such as the 3mm titanium sheet which is the lower limit for titanium sheets. There are sheets up to 250mm thickness. He width of the plates range from 1000mm to 3000mm and the lengths range up to 6000mm. The Titanium metal strip is used in linings of corrosive applications. The strips are also used as replacements to wide metallic elements with low strength. The applications of titanium sheets are widespread. The high strength of the AMS 4901 Titanium Sheet makes it suitable for aerospace and aircraft applications. The material is also highly corrosion resistant. So a small part of the sheet such as a Titanium Strip can do the job of a large piece of steel. There are different types and finishes to the sheets such as the Perforated Titanium Sheet. Please feel free to contact us for any of your custom orders.

Table of Content - Pure Titanium Sheet Standard Size And Specification - Pure Titanium Rib Plate Density - Titanium Armor Plate Melting Range - Titanium Coil Size chart - Common Types Of Titanium Plate - Titanium Polished Plate Thikness - AMS 4901 Titanium Sheet Weight Chart - Titanium Sheet Imperial Dimensions - Titanium Metal Strip Metric Dimensions - Ti Alloy Foil Composition Chart - Titanium Strip Mechanical Properties Chart - Equivalent Of Titanium Rolling Sheet

Pure Titanium Sheet Standard Size And Specification

| SHEET, PLATE & COIL | ||

|---|---|---|

Sizes: Sheet & Plate .012 TO 4.00 X r/w X R/L Sizes: Coil .001 to .011 x R/W x R/L |

SPECIFICATIONS | GRADE |

| AMS-4911, 4907,4905, MIL-T-9046, ASTM-F136 | 6AL-4V, 6AL-4V ELI | |

| DMS-1592, GM-3103,12TM-B265 | ||

| AMS,4919, MIL-T-9046, DMS-2275, AMS-T-9046 | 6AL-2SN-4ZR-2MO | |

| GM-3104, B50TF21 | ||

| AMS-4918, MIL-T-9046, DMS-1879, AMS-T-9046 | 6AL-6V-2SN | |

| AMS-4909, 4910, MIL-T-9046, AMS-T-9046 | 5AL-2.55N, 5-2.5 ELI | |

| AMS-4915, 4916, DMS-1784 | BAL-IMO-1V | |

| AMS-4900, 4902 | CP-GRADES 1,2,3,4 | |

| MIL-T-9046, AMS-T-9046, DMS-1536, ASTM-B265 | ||

| AMS-4914 | 15V-3CR-3SN-3AL | |

Supplier Of Titanium Coil In Bhopal, India, Titanium Armor Plate Specification, Buy Titanium Polished Plate At Factory Price.

| Material | Pure Titanium plate and titanium alloy |

|---|---|

| Surface | Hot rolled plate (HR), Cold rolled sheet (CR), No.1 finish hot rolled ASTM B265 Titanium Plate, BA, No.3, No.4, No.6, No.1, No. 2D, No. 2B, BA NO(8), No.7, 2B, 2D, SATIN (Met with Plastic Coated), 2B, 1D, No.4, 8K, BA, hairline, brush, satin, mirror etc. |

| Standard | ASTM B265, ASME SB265, AMS 4900, AMS 4901, AMS 4902 |

| Thickness | 0.3 to 1200 milimeter or as required |

| Type | Clad Plate, Rolling Plate, Flat Shim, Plain Sheet, Rolling Sheet Rolls, Foils, Coils, Plate, Strip, Sheet, Flats, Blank (Circle), ,Flat Sheet, Shim Sheet, soft annealed, descaled, sheared, annealed, Checker Plate, tread plate |

| Process | Hot/ Cold Rolled |

| Length | 0-12 milimeter or as required |

| Width | 0 - 2500 milimeter or as required |

Pure Titanium Rib Plate Density

| Titanium alloy Plate density |

| 0.1630 lb/in³ 4.512 g/cm³ |

Titanium Armor Plate Melting Range

We provide Multiple Payment Options Of Titanium Metal Strip, Contact US Today For Buy Pure Titanium Rib Plate, Distributor Of Titanium Hot Rolled Plates In India.

| ASTM B265 Titanium Plate melting range |

| 3135°F 1725°C |

Titanium Coil Size chart

| Stocked Sizes | |

|---|---|

| Size (in inches) | Size (in milimeter) |

| .125" | 3.18 |

| .134" | 3.40 |

| .156" | 3.96 |

| .187" | 4.75 |

| .250" | 6.35 |

| .312" | 7.92 |

| .375" | 9.53 |

| .500" | 12.7 |

| .601" | 15.9 |

| .750" | 19.1 |

| .875" | 22.2 |

| 1" | 25.4 |

| 1.125" | 28.6 |

| 1.250" | 31.8 |

| 1.500" | 38.1 |

| 1.750" | 44.5 |

| 2" | 50.8 |

| 2.500" | 63.5 |

| 3" | 76.2 |

Common Types Of Titanium Plate

Pure Titanium Rib Plate

Pure Titanium Rib Plate

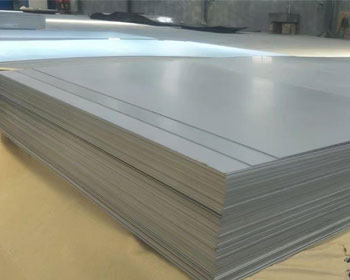

Pure Titanium Sheet

Pure Titanium Sheet

Titanium Coil

Titanium Coil

Titanium Armor Plate

Titanium Armor Plate

Titanium Polished Plate

Titanium Polished Plate

Titanium Metal Strip

Titanium Metal Strip

Titanium Hot Rolled Plates

Titanium Hot Rolled Plates

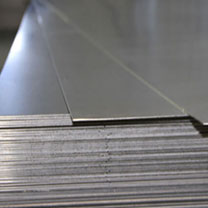

Titanium Sheet

Titanium Sheet

AMS 4901 Titanium Sheet

AMS 4901 Titanium Sheet

Titanium Strip

Titanium Strip

Ti Alloy Foil

Ti Alloy Foil

Titanium Rolling Sheet

Titanium Rolling Sheet

Titanium Polished Plate Thikness

Titanium Alloy Thin Sheet Stockist In India, Fastest Growing Supplier Of Titanium Sheet, Get at discount of Titanium Strip, Ti Alloy Foil Distributor In India.

| Thickness | Grades |

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN |

AMS 4901 Titanium Sheet Weight Chart

| Thickness (inches) | Density | Plate Weight per Unit Area |

|---|---|---|

| 3/16 | 0.315 lbs/in³8.72 g/cm³ | 0.06000 lbs/in²42.184176 kg/m² |

| 1/4 | 0.315 lbs/in³8.72 g/cm³ | 0.08 lbs/in²56.245568 kg/m² |

| 3/8 | 0.315 lbs/in³8.72 g/cm³ | 0.121 lbs/in²85.0714216 kg/m² |

| 1/2 | 0.315 lbs/in³8.72 g/cm³ | 0.161 lbs/in²113.1942056 kg/m² |

| 5/8 | 0.315 lbs/in³8.72 g/cm³ | 0.196 lbs/in²137.8016416 kg/m² |

| 3/4 | 0.315 lbs/in³8.72 g/cm³ | 0.235 lbs/in²165.221356 kg/m² |

| 7/8 | 0.315 lbs/in³8.72 g/cm³ | 0.274 lbs/in²192.6410704 kg/m² |

| 1 | 0.315 lbs/in³8.72 g/cm³ | 0.313 lbs/in²220.0607848 kg/m² |

| 1 1/4 | 0.315 lbs/in³8.72 g/cm³ | 0.391 lbs/in²274.9002136 kg/m² |

| 1 1/2 | 0.315 lbs/in³8.72 g/cm³ | 0.47 lbs/in²330.442712 kg/m² |

| 1 3/4 | 0.315 lbs/in³8.72 g/cm³ | 0.549 lbs/in²385.9852104 kg/m² |

| 2 | 0.315 lbs/in³8.72 g/cm³ | 0.627 lbs/in²440.8246392 kg/m² |

| 2 1/4 | 0.315 lbs/in³8.72 g/cm³ | 0.705 lbs/in²495.664068 kg/m² |

| 2 1/2 | 0.315 lbs/in³8.72 g/cm³ | 0.784 lbs/in²551.2065664 kg/m² |

| 2 3/4 | 0.315 lbs/in³8.72 g/cm³ | 0.862 lbs/in²606.0459952 kg/m² |

| 3 | 0.315 lbs/in³8.72 g/cm³ | 0.941 lbs/in²661.5884936 kg/m² |

Titanium Sheet Imperial Dimensions

| Plate Surface finish | Width (max inches) | Gauge (inches) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed Plate | 72* | 10–24 |

| 2D – Cold rolled, heat treated, pickled plate | 60 | 12–24 |

| BA Mexinox only | 48 | 18–28 |

| Polished plate (not brushed) | 60 | 11–24 |

| Temper rolled plate Mexinox only | 48 | 13–29 |

Titanium Metal Strip Metric Dimensions

Refer Titanium Rolling Sheet Dimensions And Weight Chart, Looking to buy Titanium Plate? contact Suryadeep Industry, A Reliable Perforated Titanium Sheet Distributor in India

| Plate Surface finish | Width (max milimeter) | Thickness (milimeter) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed plate | 2032 | 0.25–8.0 |

| 2D – Cold rolled, heat treated, pickled plate | 1524 | 0.4–6.35 |

| 2E – Cold rolled, heat treated, mechanically descaled plate | 2032 | 0.4–8.0 |

| 2R – Cold rolled, bright annealed plate | 1524 | 0.25–3.5 |

| 2H – Work hardened plate | 1524 | 0.4–6.35 |

| Polished, brushed plate | 1524 | 0.5–4.0 |

Ti Alloy Foil Composition Chart

| Titanium Grade | 1 | 2 | 3 | 4 | 5 | 7 | 9 | 12 |

|---|---|---|---|---|---|---|---|---|

| Al | ... | ... | ... | ... | 5.5~6.75 | ... | 2.5~3.5 | ... |

| C | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| Ni | ... | ... | ... | ... | ... | ... | ... | 0.2~0.4 |

| O | 0.18 | 0.25 | 0.35 | 0.40 | 0.20 | 0.25 | 0.15 | 0.25 |

| Mo | ... | ... | ... | ... | ... | ... | ... | 0.6~0.9 |

| N | 0.03 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.03 |

| Pd | ... | ... | ... | ... | ... | 0.12~0.25 | ... | ... |

| H | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 |

| V | ... | ... | ... | ... | 3.5~4.5 | ... | 2.0~3.0 | ... |

| Iron | 0.20 | 0.30 | 0.30 | 0.50 | 0.40 | 0.30 | 0.25 | 0.30 |

| Other | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Total Maximum | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

Titanium Strip Mechanical Properties Chart

| Grade | Tensisle Strength | Yield Strength | Bend Test | Elogation in 2 in. or 50mm min.,% | |||||

|---|---|---|---|---|---|---|---|---|---|

| Min | Min | Min | Min | Max | Max | Under 0.070 in. (1.8mm) Thickness | 0.070 to 0.187 in. (1.8mm to 4.75mm) Thickness | ||

| Mpa | Ksi | Mpa | Ksi | Mpa | Ksi | ||||

| 1 | 240 | 35 | 138 | 20 | 310 | 45 | 1.5T | 2T | 24 |

| 2 | 345 | 50 | 275 | 40 | 450 | 65 | 2T | 2.5T | 20 |

| 3 | 450 | 65 | 380 | 55 | 550 | 80 | 2T | 2.5T | 18 |

| 4 | 550 | 80 | 483 | 70 | 655 | 95 | 2.5T | 3T | 15 |

| 5 | 895 | 130 | 828 | 120 | ... | ... | 4.5T | 5T | 10 |

| 7 | 345 | 50 | 275 | 40 | 450 | 65 | 2T | 2.5T | 20 |

| 9 | 620 | 90 | 483 | 70 | ... | ... | 2.5T | 3T | 15 |

| 12 | 483 | 70 | 345 | 50 | ... | ... | 2T | 2.5T | 18 |

| COMMERCIALLY PURE TITANIUM SHEET | |||

|---|---|---|---|

| GRADE | FRANCE | BRITISH STANDARD |

GERMAN AEROSPCE |

| GR.1 | T-35 | BS 2TA 1 | 3.7024 |

| GR.2 | T-40 | BS 2TA 2 | 3.7034 |

| GR.3 | T-50 | DTD5023 | 3.7054 |

| GR.4 | T-60 | BS 2TA 6 | 3.7064 |

| AMS | Properties |

|---|---|

| 4900L | Sheet, Strip and Plate, C.P., Annealed, 55.0 ksi (379 MPa) Yield Strength |

| 4901M | Sheet, Strip, and Plate, C.P. Annealed, 70.0 ksi (485MPa) |

| 4902G | Sheet, Strip, and Plate, C.P. Annealed, 40.0 ksi (276 MPa) Yield Strength |

| 4905B | Damage-Tolerant Grade Plate 6AL – 4V, Beta, Annealed |

| 4907F | Sheet, Strip, and Plate 6AL-4V, Extra Low Interstitial Annealed |

| 4908F | Sheet and Strip, 8Mn, Annealed, 110,000 psi (760 MPa) Yield Strength |

| 4909F | Sheet, Strip, and Plate 5AL -2.5Sn, Extra Low Interstitial, Annealed |

| 4910K | Sheet, Strip and Plate 5AL – 2.5Sn Annealed |

| 4911H | Sheet, Strip, and Plate, 6AL – 4V, Annealed |

| 4914A | Cold Rolled Sheet and Strip, 15V - 3AL – 3Cr – 3Sn Solution Heat Treated |

| 4915G | Sheet, Strip, and Plate, 8AL – 1V – 1Mo, Single Annealed |

| 4916F | Sheet, Strip, and Plate, 8AL – 1Mo – 1V, Duplex Annealed |

| 4917E | Sheet, Strip, and Plate, 13.5V – 11Cr – 3.0AL, Solution Heat Treated |

| 4918H | Sheet, Strip, and Plate, 6AL – 6V- 2Sn Annealed |

| 4919C | Sheet, Strip, and Plate, 6AL– 2Sn – 4Zr – 2M0 – 0.08Si, Duplex Annealed |

Equivalent Of Titanium Rolling Sheet

| Specification | Equivalent Spec | Equivalent Grade | |||

|---|---|---|---|---|---|

| British Standard | USA | Rolls Royce | Germany | France | General Engineering |

| TA11 | AMS4928 | MSRR8652 | 3.7164-2 | AIR 9183 TA6V | 6AL-4V |

| TA12 | AMS4935 | MSRR8614 | 6AL-4V | ||

| MIL-T-9047 | 6AL-4V | ||||

| Titanium Sheet | |

|---|---|

| Grade | Specification |

| C.P.3, A40, 55A | AMS-4902 / MIL-T 9046, TYPE 1 COMP. A / C.P.3 |

| C.P.1, A70, 75A | AMS-4901 / MIL-T 9046, TYPE 1 COMP. B / C.P.1, DMS 1536 |

| 6AL-4V ANN | AMS-4911 / MIL-T 9046, TYPE 3 COMP.C / AB1, DMS 1592 |