Check Attractive Price Offer On ASTM A204 16Mo3 Molybdenum Alloy Steel Sheet, 16Mo3 Pressure Vessel Steel Plates In India

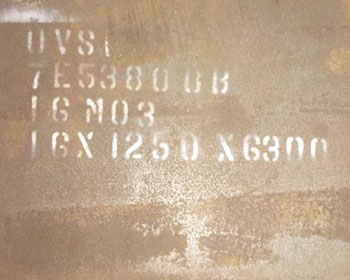

16MO3 Steel Plates is made up of a chromium nickel molybdenum alloy that has carbon, manganese, sulfur, nitrogen, copper, silicon and phosphorus in the composition as well. Suryadeep Industry is a leading distributor of the ASTM A204 16Mo3 Molybdenum Alloy Steel Plates products in various scales and standards. The plates are available under the specification ASTM 204 and the thickness ranges from 5mm to 150mm in this specification. The 16Mo3 Pressure Vessel Steel Plates are made in lengths of 3000mm to 18000mm with the width ranging from 1000mm to 4500mm. The plates could be hot rolled and treated. The treatment for SA 204 Gr B 16 molybdenum Plate could be rolling, normalizing, quenched and tempered. The material is strong and it gives the plates good strength and corrosion resistance properties.

The 16Mo3 Cr-Mo steel plates has 440-590MPa minimum tensile strength and 220-275MPa minimum yield strength depending on the grades. The material is known for its wear and tear resistance which is useful in different industrial applications. The 16 Molybdenum Alloy Steel hot rolled Plates are used in waste recycling, incineration, venting, industrial exhaust systems and power plants. The SA 204 Gr B 16 Molybdenum Plates can withstand temperatures up to 500 degrees Celsius. This makes the material suitable for high temperature services. While undergoing high temperatures, the ASME SA 204 16Mo3 EN10028 Plate is also resistant to creep; this is good at salt water and corrosive environments. There are different international specifications such as the Cr-Mo 16Mo3 WNR 1.5415 Steel Plate for these products. We manufacture and supply all different types of plates for different application requirements such as the 16Mo3 Chrome Moly Alloy Steel Cold Rolled Plates. Please contact us to know more technical details about the products, the storage and production capacities or the pricing information of the 16 Molybdenum Plates.

16Mo3 Pressure Vessel Steel Plates Most Common Specification

| Production |

Hot-Rolled (HR) / Cold-Rolled (CR) |

| Thickness |

6 milimeter to 300 milimeter |

| Heat Treatment |

Rolled/Normalised/N+T/QT |

| Length |

3000 milimeter to 15000 milimeter |

| Width |

1500 milimeter to 4050 milimeter |

| Dimension range |

1.5 milimeter -260 milimeter x 1000 milimeter-4000 milimeter x 1000 milimeter-18000 milimeter |

Suppliers Of SA 204 Gr B 16mo3 Plate In Bhopal, India, 16MO3 Steel Plate Specification, Buy Large Diameter 16Mo3 Cr-Mo steel plate At Factory Price.

SA 204 Gr B 16mo3 Plate Equivalent Material

| ASTM/ASME |

BS |

DIN |

EN |

| ASTM A204Gr.B |

1501–243b |

17155 |

10028-2 |

16Mo3 Cr-Mo steel plate Chemical Formula

16Mo3 Steel Sheet Suppliers In India, Mechanical Properties Of 16Mo3 Alloy Steel hot rolled Plates, Get at discount of SA 204 Gr B 16mo3 Plate.

| C |

Mn |

P |

S |

Si |

Cr |

Mo |

Ni |

N |

Cu |

| 0.12/0.20 |

0.40/0.90 |

0.025 |

0.010 |

0.35 |

0.030 |

0.25/0.35 |

0.30 |

0.012 |

0.30 |

ASME SA 204 16Mo3 EN10028 Plate Mechanical Strength

| YIELD (MPA) |

TENSILE (MPA) |

ELONG. A (%) |

IMPACT (J)* |

| 270 |

440 - 590 |

22 |

31 |

List Of 16MO3 Steel Plate Types

View ASME SA 204 16Mo3 EN10028 Plate Dimensions And Cr-Mo 16Mo3 WNR 1.5415 Steel Plate Properties, 16Mo3 Chrome Moly Alloy Steel Cold Rolled Plates Distributors In India, Get Cr Mo 16Mo3 Plates With Best Price & Fast Delivery.

ASTM A204 16Mo3 Alloy Steel plates

ASTM A204 16Mo3 Alloy Steel plates

16Mo3 Cr-Mo Steel Plates

16Mo3 Cr-Mo Steel Plates

16Mo3 High Tensile Alloy Steel Plate

16Mo3 High Tensile Alloy Steel Plate

Alloy Steel ASTM A204 16MO3 Plates

Alloy Steel ASTM A204 16MO3 Plates

ASTM A204 AS 16MO3 Sheets

ASTM A204 AS 16MO3 Sheets

16mo3 Alloy Cr Plates

16mo3 Alloy Cr Plates

Alloy 16mo3 Cold Rolled Plate

Alloy 16mo3 Cold Rolled Plate

DIN 1.5415 Plates

DIN 1.5415 Plates

UNS K11562 Plates

UNS K11562 Plates

CrMo 16Mo3 Plates

CrMo 16Mo3 Plates

16Mo3 Pressure Vessel Steel Plates

16Mo3 Pressure Vessel Steel Plates

SA 204 Gr B 16mo3 Plate

SA 204 Gr B 16mo3 Plate

Cr-Mo 16Mo3 WNR 1.5415 Steel Plate Size Chart

| 1/8" |

3/8" |

3/4" |

1-1/2" |

3" |

| 3/16" |

1/2" |

1" |

2" |

4" |

| 1/4" |

5/8" |

1-1/4" |

2-1/2" |

|

Cr Mo 16Mo3 Plates Thickness

We provide Multiple Payment Options Of ASME SA 204 EN10028 16Mo3 Chrome Moly plate, Contact US Today to Buy 16MO3 Steel Plate Stockist In India, Distributors Of 16Mo3 (1.5415) Molybdenum Alloy Steel Plates In India.

| Thickness |

Length |

Width |

| 4mm |

6000milimeter |

2000milimeter |

| 5mm |

6000milimeter |

2000milimeter |

| 6mm |

6000milimeter |

2000milimeter |

| 6mm |

6000milimeter |

2500milimeter |

| 8mm |

6000milimeter |

2000milimeter |

| 8mm |

6000milimeter |

2500milimeter |

| 10mm |

6000milimeter |

2000milimeter |

| 12mm |

6000milimeter |

2000milimeter |

| 15mm |

6000milimeter |

2000milimeter |

| 16mm |

6000milimeter |

2000milimeter |

| 20mm |

6000milimeter |

2000milimeter |

| 25mm |

6000milimeter |

2000milimeter |

| 32mm |

6000milimeter |

2000milimeter |

| 40mm |

6000milimeter |

2000milimeter |

| 50mm |

6000milimeter |

2000milimeter |

| 60mm |

3400milimeter |

1800milimeter |

ASTM A204 16Mo3 Molybdenum Alloy Steel Plate Tensile Requirements

|

Grade A |

Grade B |

Grade C |

| [MPa] |

ksi |

ksi |

[MPa] |

[MPa] |

ksi |

| Elongation in 8 |

17B |

19B |

16B |

|

|

|

| Tensile strength |

[450-585] |

65-85 |

70-90 |

[485-620] |

[515-655] |

75-95 |

| Elongation in 2 |

21B |

23B |

20B |

|

|

|

| Yield strength, min.A |

[255] |

37 |

40 |

[275] |

[295] |

43 |

16Mo3 Sheets Elasticity module

| Qualities |

Temperature |

| 20ºC |

300ºC |

400ºC |

500ºC |

600ºC |

| 16 Mo3 |

21.000 kg/mm2 |

18.500 kg/mm2 |

17.500 kg/mm2 |

16.500 kg/mm2 |

15.500 kg/mm2 |

ASTM A204 Alloy Steel 16mo3 Plates Temperature

| Qualities |

Rate of dilatation |

Temperature |

| 100 ºC |

200 ºC |

300 ºC |

400 ºC |

500 ºC |

600 ºC |

| 16 Mo 3 |

10-6 mm ºC |

11,1 |

12,1 |

12,9 |

13,5 |

13,9 |

14,1 |

Grade 16MO3 Alloy Steel Plates Elastic warm limit values

| Qualities |

Elastic limit |

Temperature |

| 20 ºC |

200 ºC |

250 ºC |

300 ºC |

350 ºC |

400 ºC |

450 ºC |

500 ºC |

| 16 Mo 3 |

kg/mm2 mínimo |

30 |

27 |

25 |

22 |

20 |

19 |

18 |

16 |

SA204 Alloy Steel 16MO3 Plates Approximate equivalents

|

IHA |

AFNOR |

ASTM |

BS |

| 16 Mo3 |

F-251 |

15 D 3 |

A-204 |

240-1501 |

16Mo3 / SA 204 Plates Application

- Conveyor Buckets

- Drag line Bucket Wear Liners

- Dump Truck Liners

- Cutting Edges

- Crusher Liner Plates

- Screen Plates - Chute Liners

- Ripper Tyne

- Loading Buckets

- Bulldozers

- Hoppers

DIN 1.5415 Sheets Material Testing

- Mechanical Testing Such as Tensile of Area

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Positive Material Identification – PMI Testing

- Flattening Test

- Micro and MacroTest

- Pitting Resistance Test

- Flaring Test

- Intergranular Corrosion (IGC) Test

Finishes Of 16Mo3 Sheets & Plates

| Surface Finish |

Definition |

Application |

| 2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA |

Those processed with bright heat treatment after cold rolling. |

Kitchen utensils, Electric equipment, Building construction. |

| NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS RGr 51. |

Kitchen utensils, Building construction. |

| NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction, Medical equipment. |

| HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. |

Building Construction. |

| NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

Chemical tank, pipe |

16Mo3 2B Finish Sheets Sizs

| GAUGE (inches) |

WIDTH (inches) |

LENGTH (inches) |

| 0.3750 |

60/96/120 |

480 |

| 0.5000 |

60/96/120 |

480 |

| 0.6250 |

60/96/120 |

480 |

| 0.7500 |

60/96/120 |

480 |

| 0.8750 |

60/96/120 |

480 |

| 1.0000 |

60/96/120 |

480 |

| 1.1250 |

60/96/120 |

480 |

| 1.2500 |

60/96/120 |

480 |

| 1.5000 |

60/96/120 |

480 |

| 1.7500 |

60/96/120 |

480 |

| 2.0000 |

60/96/120 |

480 |

| 2.2500 |

60/96/120 |

480 |

| 2.5000 |

60/96/120 |

480 |

| 2.7500 |

60/96/120 |

480 |

| 3.0000 |

60/96/120 |

480 |

| 3.5000 |

60/96/120 |

480 |

| 4.0000 |

60/96/120 |

480 |

Alloy Steel 16MO3 Plate Weight Chart

Sheet – Metric

Thickness

mm |

Size

m |

Weight

kg/sheet |

| 0.300 |

2 x 1 |

4.7 |

| 0.376 |

2 x 1 |

5.9 |

| 0.400 |

2 x 1 |

6.3 |

| 0.457 |

2 x 1 |

7.2 |

| 0.500 |

2 x 1 |

7.9 |

| 0.559 |

2 x 1 |

8.8 |

| 0.600 |

2 x 1 |

9.4 |

| 0.710 |

2 x 1 |

11.1 |

| 0.800 |

2 x 1 |

12.6 |

| 0.914 |

2 x 1 |

14.3 |

| 1.000 |

2 x 1 |

15.7 |

| 1.200 |

2 x 1 |

18.8 |

| 1.220 |

2 x 1 |

19.2 |

| 1.270 |

2 x 1 |

19.9 |

| 1.420 |

2 x 1 |

22.3 |

| 1.600 |

2 x 1 |

25.1 |

| 1.780 |

2 x 1 |

28.0 |

| 2.000 |

2 x 1 |

31.4 |

| 2.030 |

2 x 1 |

31.9 |

| 2.286 |

2 x 1 |

35.9 |

| 2.500 |

2 x 1 |

39.3 |

| 2.540 |

2 x 1 |

39.9 |

| 2.640 |

2 x 1 |

41.4 |

| 3.000 |

2 x 1 |

47.1 |

| 3.250 |

2 x 1 |

51.0 |

| 4.000 |

2 x 1 |

62.8 |

| 4.060 |

2 x 1 |

63.7 |

| 4.460 |

2 x 1 |

70.0 |

| 4.760 |

2 x 1 |

74.7 |

| 5.000 |

2 x 1 |

78.5 |

| 6.000 |

2 x 1 |

94.2 |

Sheet – Imperial

Thickness

in |

Size

ft |

Weight

lbs/sheet |

| 0.012 |

10×3 |

14.7 |

| 0.014 |

10×3 |

17.2 |

| 0.016 |

10×3 |

19.6 |

| 0.018 |

10×3 |

22.1 |

| 0.020 |

10×3 |

24.5 |

| 0.022 |

10×3 |

27.0 |

| 0.024 |

10×3 |

29.4 |

| 0.028 |

10×3 |

34.4 |

| 0.032 |

10×3 |

39.3 |

| 0.036 |

10×3 |

44.2 |

| 0.040 |

10×3 |

49.1 |

| 0.047 |

10×3 |

57.7 |

| 0.048 |

10×3 |

58.9 |

| 0.050 |

10×3 |

61.3 |

| 0.056 |

10×3 |

68.7 |

| 0.063 |

10×3 |

77.3 |

| 0.070 |

10×3 |

85.9 |

| 0.078 |

10×3 |

95.7 |

| 0.080 |

10×3 |

98.2 |

| 0.090 |

10×3 |

110.4 |

| 0.100 |

10×3 |

120.2 |

| 0.098 |

10×3 |

120.2 |

| 0.104 |

10×3 |

122.7 |

| 0.118 |

10×3 |

144.8 |

| 0.128 |

10×3 |

157.0 |

| 0.157 |

10×3 |

192.6 |

| 0.160 |

10×3 |

196.3 |

| 0.176 |

10×3 |

215.9 |

| 0.187 |

10×3 |

229.4 |

| 0.197 |

10×3 |

241.7 |

| 0.236 |

10×3 |

289.5 |

Plate – Metric

Thickness

mm |

Size

m |

Weight

kg/plate |

| 6.35 |

2 x 1 |

99.7 |

| 10.00 |

2 x 1 |

157.0 |

| 12.70 |

2 x 1 |

199.4 |

| 15.00 |

2 x 1 |

235.5 |

| 20.00 |

2 x 1 |

314.0 |

| 25.40 |

2 x 1 |

398.8 |

| 30.00 |

2 x 1 |

471.0 |

| 38.10 |

2 x 1 |

598.2 |

| 40.00 |

2 x 1 |

628.0 |

| 50.00 |

2 x 1 |

785.0 |

| 50.80 |

2 x 1 |

797.6 |

| 60.00 |

2 x 1 |

942.0 |

| 63.50 |

2 x 1 |

997.0 |

| 70.00 |

2 x 1 |

1099.0 |

| 76.20 |

2 x 1 |

1196.3 |

| 80.00 |

2 x 1 |

1256.0 |

| 90.00 |

2 x 1 |

1413.0 |

| 100.00 |

2 x 1 |

1570.0 |

| 101.60 |

2 x 1 |

1595.1 |

| 110.00 |

2 x 1 |

1727.0 |

| 120.00 |

2 x 1 |

1884.0 |

| 127.00 |

2 x 1 |

1993.9 |

| 130.00 |

2 x 1 |

2041.0 |

| 140.00 |

2 x 1 |

2198.0 |

| 150.00 |

2 x 1 |

2355.0 |

| 152.40 |

2 x 1 |

2392.7 |

Plate – Imperial

Thickness

in |

Size

ft |

Weight

lbs/plate |

| 1/4 |

10 x 3 |

306.7 |

| 1/2 |

10 x 3 |

613.4 |

| 3/4 |

10 x 3 |

920.2 |

| 1 |

10 x 3 |

1226.9 |

| 1 1/4 |

10 x 3 |

1533.6 |

| 1 1/2 |

10 x 3 |

1840.3 |

| 2 |

10 x 3 |

2453.8 |

| 2 1/2 |

10 x 3 |

3067.2 |

| 2 3/4 |

10 x 3 |

3373.9 |

| 3 |

10 x 3 |

3680.6 |

| 4 |

10 x 3 |

4907.5 |

| 5 |

10 x 3 |

6134.4 |

| 5 1/2 |

10 x 3 |

6747.8 |

| 6 |

10 x 3 |

7361.3 |

ASTM A204 16Mo3 Alloy Steel plates

ASTM A204 16Mo3 Alloy Steel plates

16Mo3 Cr-Mo Steel Plates

16Mo3 Cr-Mo Steel Plates

16Mo3 High Tensile Alloy Steel Plate

16Mo3 High Tensile Alloy Steel Plate

Alloy Steel ASTM A204 16MO3 Plates

Alloy Steel ASTM A204 16MO3 Plates

ASTM A204 AS 16MO3 Sheets

ASTM A204 AS 16MO3 Sheets

16mo3 Alloy Cr Plates

16mo3 Alloy Cr Plates

Alloy 16mo3 Cold Rolled Plate

Alloy 16mo3 Cold Rolled Plate

DIN 1.5415 Plates

DIN 1.5415 Plates

UNS K11562 Plates

UNS K11562 Plates

CrMo 16Mo3 Plates

CrMo 16Mo3 Plates

16Mo3 Pressure Vessel Steel Plates

16Mo3 Pressure Vessel Steel Plates

SA 204 Gr B 16mo3 Plate

SA 204 Gr B 16mo3 Plate