Get instant delivery Of Rockstar Extreme Steel Plates, Extreme Rockstar Sheet

Rockstar Wear Plates is the hardest of all wear plates in the world. It has the Rockwell hardness 60 and HBW up to 700. There is no other hard steel that surpasses these measures. Suryadeep Industry is a Distributor and supplier of this Extreme abrasion resistance sheet and plates types. These are used in liner plates, cladding, covering and abrasion resistant layers of heavy machineries and so on. The sheets and plates come in various thicknesses ranging from 8mm to 19mm and widths up to 2000mm with lengths ranging up to 14630mm.

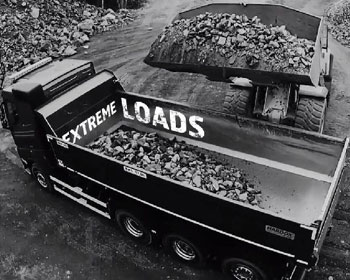

As the Rockstar® Extreme steel sheet is the world’s hardest steel plates type, it also has very high mechanical properties. The chemical composition includes carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel and molybdenum in the composition with nickel being 2.5% of the weight. The Rockstar® steel Plates has surface properties and tolerances according to EN 10163-2 and EN 10029. The Rockstar® Sheet is used in heavy applications with yield strengths ranging above 1300MPa. The material is used in excavator buckets, earth moving machines, storage containers, transportation systems and in linings of larger machinery components. Please contact us for more information about the Rockstar® Extreme Plates products and details.

Abrasion Rockstar Extreme Plate Sizes And Schedule Specifications

Specification Of Rockstar Extreme Wear Plates, Buy Abrasion Resistance Sheet Best Price & Fast Delivery.

| Item |

Abrasion Resistant Plate |

| Width |

up to 2000 milimeter |

| Hardness |

570 to 630 HBW |

| Heat Treatment |

N, Q+T |

| Thickness |

8 to 19 milimeter |

| Dimensions |

2000 x 4000 milimeter |

| Surface Paint |

EP, PE, HDP, SMP, PVDF |

Rockstar Extreme Sheets Chemical Composition Standard

Check Rockstar® Extreme Steel Sheet, Abrasion Resistant Rockstar Extreme Chemical Composition And Wear Rockstar Extreme Plates, Abrasion Rockstar Extreme Plates Mechanical Properties.

| Thickness (mm) |

Typical Hardness (HRC) |

| 8.0 - 19.0 |

57 - 63 |

Different Rockstar Extreme Wear Plate Types

Get Rockstar® Extreme Steel Plates At Best Price, Types Of Abrasion Resistant Rockstar Extreme Steel Plates, We provide Rockstar® Extreme Sheet, Rockstar Extreme Wear Sheet Expert Cutting Service In Bhopal, India.

Rockstar Extreme Steel Plates

Rockstar Extreme Steel Plates

Rockstar Extreme Plates

Rockstar Extreme Plates

Rockstar Extreme Wear Plate

Rockstar Extreme Wear Plate

Extreme Abrasion Resistance Sheet

Extreme Abrasion Resistance Sheet

Rockstar® Extreme Steel Sheet

Rockstar® Extreme Steel Sheet

Abrasion Resistant Rockstar Extreme

Abrasion Resistant Rockstar Extreme

Wear Rockstar Extreme Plates

Wear Rockstar Extreme Plates

Abrasion Rockstar Extreme Plate

Abrasion Rockstar Extreme Plate

Rockstar® Extreme Steel Plate

Rockstar® Extreme Steel Plate

Abrasion Resistant Rockstar Extreme Steel Plate

Abrasion Resistant Rockstar Extreme Steel Plate

Rockstar® Extreme Sheet

Rockstar® Extreme Sheet

Rockstar Extreme Wear Sheet

Rockstar Extreme Wear Sheet

Wear Rockstar Extreme Plates Mechanical Properties Database

Buy Rockstar Wear Resistant Steel Plates Certified & Tested Materials, We provide Multiple Payment Options Of Rockstar® Extreme Plates, Extreme Abrasion Resistance Plate Physical Properties Of Rockstar Sheets.

| P |

C |

Cr |

Si |

Ni |

Mn |

Mo |

S |

B |

| 0.015 |

0.47 |

1.20 |

0.50 |

2.50 |

1.40 |

0.80 |

0.010 |

0.005 |

Rockstar Extreme Steel Plates Equivalent

| Thickness(mm) |

8.0 - 19.0 |

| Max CET(CEV) |

0.57 (0.69) |

| Typical CET(CEV) |

0.55 (0.66) |

Extreme Abrasion Resistance Sheet Temperatures Range

| Grade |

Plate thickness |

Minimum preheating temp. (°C) |

Maximum preheating temp. (°C) |

| Rockstar Extreme* |

8 – 19 mm |

100 |

100 |

Extreme Sheet Maximal Cutting Speed (Mm/min) For Oxy-fuel Cutting

| Max plate thickness |

Rockstar Extreme |

| 12 mm |

** |

| 15 mm |

** |

| 20 mm |

** |

| 25 mm |

|

| 30 mm |

|

| 35 mm |

|

| 40 mm |

|

| 45 mm |

|

| 50 mm |

|

| 60 mm |

|

| 70 mm |

|

| 80 mm |

|

| >80 mm |

|

Wear Rockstar Extreme Plates Laser Cutting

| Cutting method |

Kerf width |

HAZ |

Dim. tolerances |

| Laser cutting |

< 1 mm |

0.2-2 mm |

± 0.2 mm |

Abrasion Rockstar Extreme Plate Plasma Cutting

| Cutting method |

Kerf width |

HAZ |

Dim. tolerances |

| Plasma cutting |

2-6.5 mm |

2-5 mm |

± 1.0 mm |

Rockstar Extreme Wear Sheet Welding Method

| Welding method |

AWS classification |

EN classification |

| MAG/ GMAW, solid wire |

AWS A5.28 ER70X-X |

EN ISO 14341-A- G 38x |

| |

AWS A5.28 ER80X-X |

EN ISO 14341-A- G 42x |

| MAG/ MCAW, metal cored wire |

AWS A5.28 E7XC-X |

EN ISO 17632-A- T 42xH5 |

| |

AWS A5.28 E8XC-X |

EN ISO 17632-A- T 46xH5 |

| MAG/ FCAW, flux cored wire |

AWS A5.29 E7XT-X |

EN ISO 17632 -A- T 42xH5 |

| |

AWS A5.29 E8XT-X |

EN ISO 17632 -A- T 46xH5 |

| MMA (SMAW, stick) |

AWS A5.5 E70X |

EN ISO 2560-A- E 42xH5 |

| |

AWS A5.5 E80X |

EN ISO 2560-A- E 46xH5 |

| SAW |

AWS A5.23 F49X |

EN ISO 14171-A- S 42x |

| |

AWS A5.23 F55X |

EN ISO 14171-A- S 46x |

| TIG/ GTAW |

AWS A5.18 ER70X |

EN ISO 636-A- W 42x |

| |

AWS A5.28 ER80X |

EN ISO 636-A- W 46x |

Rockstar Extreme Wear Plate Solid Cemented Carbide Drill

| |

Rockstar Extreme |

| Vc (m/min) |

18-25 |

| fn (mm/rev) |

min-max |

| Diameter |

3.0-5.0 |

0.02-0.04 |

| 5.01-10.0 |

0.04-0.08 |

| 10.01-15.0 |

0.08-0.12 |

| 15.01-20.0 |

0.12-0.15 |

Extreme Abrasion Resistance Sheet Application

- Oil & Gas Suryadeep

- Petrochemical Suryadeep

- Aerospace Suryadeep

- Refineries Suryadeep

- Fertilizers Suryadeep

- Nuclear Power Plant Suryadeep

- Paper Suryadeep

- Chemical Suryadeep

Material Standards And Grades Of Hardox Extreme Plate

| USED FOR |

DIMENSIONS |

STANDARDS |

Wear Resistant

|

T: 8 - 19 mm

W: Up to 2000 mm

L: Up to 14630 mm |

EN 10029 |

Rockstar Extreme Steel Plates

Rockstar Extreme Steel Plates

Rockstar Extreme Plates

Rockstar Extreme Plates

Rockstar Extreme Wear Plate

Rockstar Extreme Wear Plate

Extreme Abrasion Resistance Sheet

Extreme Abrasion Resistance Sheet

Rockstar® Extreme Steel Sheet

Rockstar® Extreme Steel Sheet

Abrasion Resistant Rockstar Extreme

Abrasion Resistant Rockstar Extreme

Wear Rockstar Extreme Plates

Wear Rockstar Extreme Plates

Abrasion Rockstar Extreme Plate

Abrasion Rockstar Extreme Plate

Rockstar® Extreme Steel Plate

Rockstar® Extreme Steel Plate

Abrasion Resistant Rockstar Extreme Steel Plate

Abrasion Resistant Rockstar Extreme Steel Plate

Rockstar® Extreme Sheet

Rockstar® Extreme Sheet

Rockstar Extreme Wear Sheet

Rockstar Extreme Wear Sheet